High-temperature-resistant valve rod for steam turbine

A high-temperature-resistant, steam-turbine technology, applied to valve devices, mechanical equipment, engine components, etc., can solve problems such as inconvenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

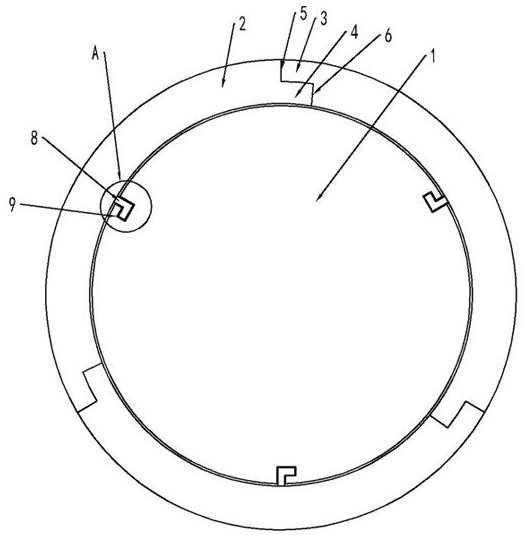

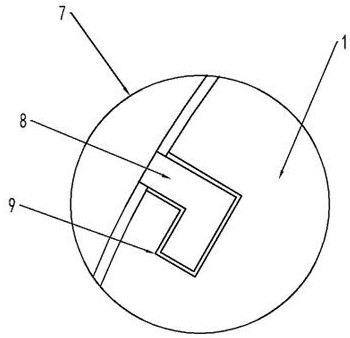

[0022] Examples such as figure 1 and 2 As shown, a high-temperature-resistant valve stem for a steam turbine includes a rod body 1. A high-temperature-resistant unit is arranged outside the rod body 1. The high-temperature-resistant unit is connected to the rod body 1 through a detachable unit to facilitate later maintenance and replacement and improve the use convenience.

[0023] The high temperature resistant unit includes a plurality of guard plates 2 , the cross section of the guard plates 2 is arc-shaped, and the plurality of guard plates 2 are arrayed in a ring on the outer circumference of the rod body 1 .

[0024] The plurality of guard plates 2 are sequentially connected end-to-end through connecting units, so as to realize complete coverage of the rod body 1 and improve the service life of the rod body 1 .

[0025] The length of the guard plate 2 is equal to the length of the rod body 1, and the guard plate 2 and the rod body 1 are bonded together, and the outer p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com