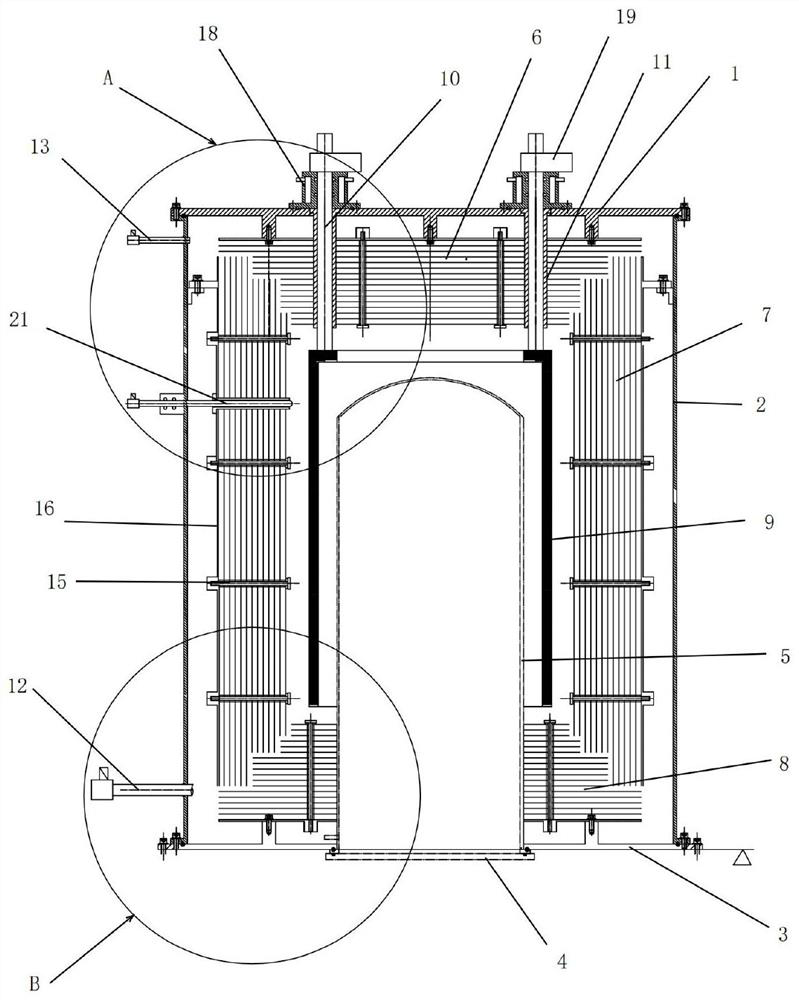

Vacuum sealing reflecting screen hearth structure of vertical high-temperature furnace

A technology of vacuum sealing and furnace structure, which is applied in the field of annealing furnace and high temperature oxidation furnace, can solve the problems that the application of high temperature furnace cannot be realized, and achieve the effects of ensuring safety and product qualification rate, avoiding the influence of high temperature, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

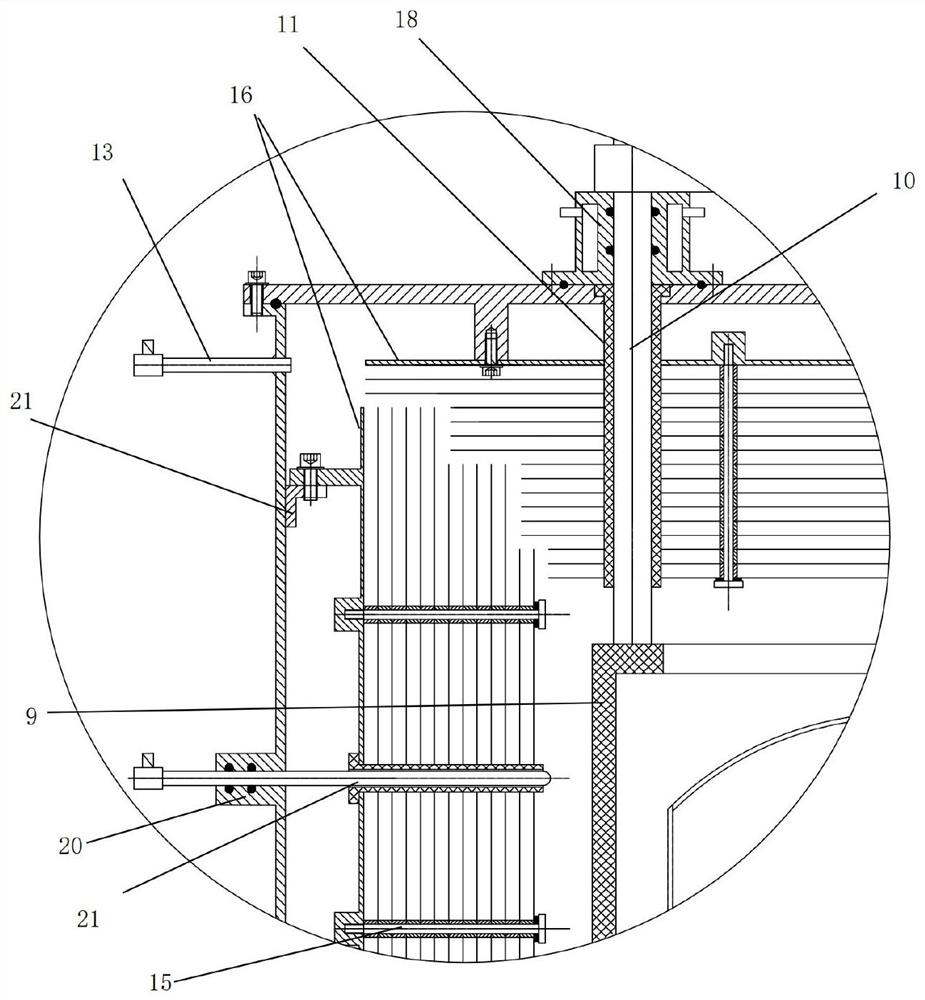

[0033] In the second embodiment, the heat shield 6 of the furnace cover, the heat shield 7 of the furnace shell, and the heat shield 8 of the furnace bottom are all composed of heat shields 14 stacked at intervals. Among them, the interval is generally between 8-10mm. This setting can firstly facilitate the formation of a labyrinth-shaped sealing seam. Second, it can also prevent the heat shields between each layer from affecting each other, because each group of heat shields The material of the heat shield 14 in the direction from the inside to the outside is changed, for example, from the inside to the outside, it is tungsten, molybdenum, stainless steel, and the material type can be two or more, depending on the maximum temperature in the furnace And the heat resistance of the heat shield material, in addition, the material selection according to the temperature also reduces the cost.

[0034] The heat shield 14 is installed on the heat shield mounting plate 16 through the ...

no. 3 example

[0036] In the third embodiment, based on the first embodiment, the outer part of the heater electrode 10 is sleeved with an electrode insulating water-cooling sealing sleeve 18, the heater electrode 10 and the electrode insulating water-cooling sealing sleeve 18 are sealed by a sealing ring, and the electrode insulating water-cooling sealing sleeve 18 It is sealed and solidified with the furnace cover 1 through a sealing ring, and a wiring assembly 19 is provided at the end of the heater electrode 10 for external power supply.

no. 4 example

[0037] In the fourth embodiment, based on the first embodiment, a furnace shell vacuum tube 12 is set through the furnace shell heat shield 7 and the furnace shell 2 to form a vacuum state in the vacuum-sealed furnace, and a furnace shell intake pipe 13 is used for Fill inert gas into the vacuum-sealed furnace, wherein the inert gas is Ar 2 or N 2One of. After evacuation to form a vacuum, the inert gas is then filled to further ensure that the furnace is in an oxygen-free state, and protect the heater 9 and the heat shield 6 of the furnace cover, the heat shield 7 of the furnace shell, and the heat shield 8 of the furnace bottom. performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com