Rapid flame-retardant solid combustion particle sampling device and sampling steps thereof

A sampling device and flame-retardant technology, which are applied in the field of rapid flame-retardant solid combustion particle sampling device and sampling steps, can solve the problems of sample distortion, inaccurate experimental results, loss of sampling significance, etc., and achieve tight connection and connection. tight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

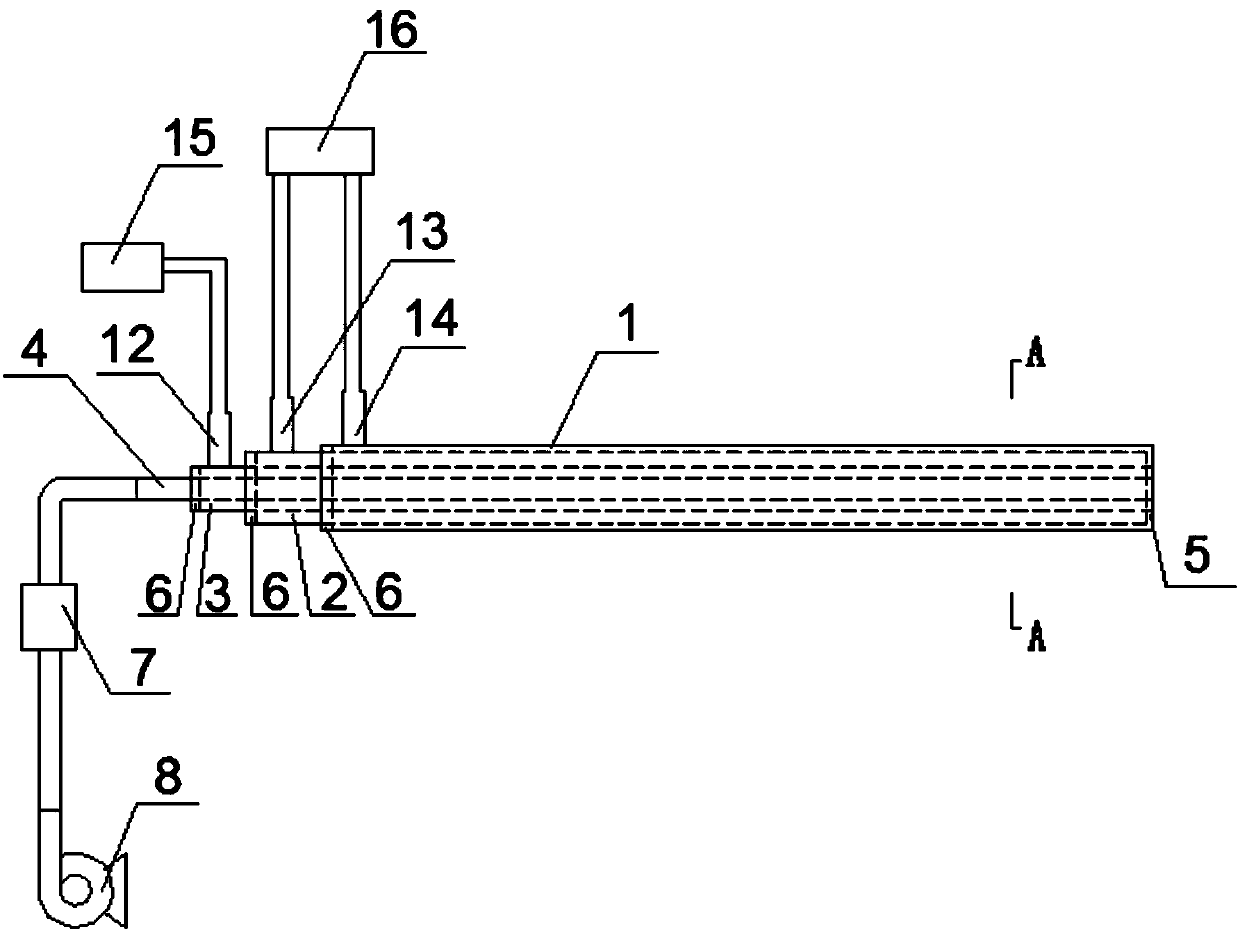

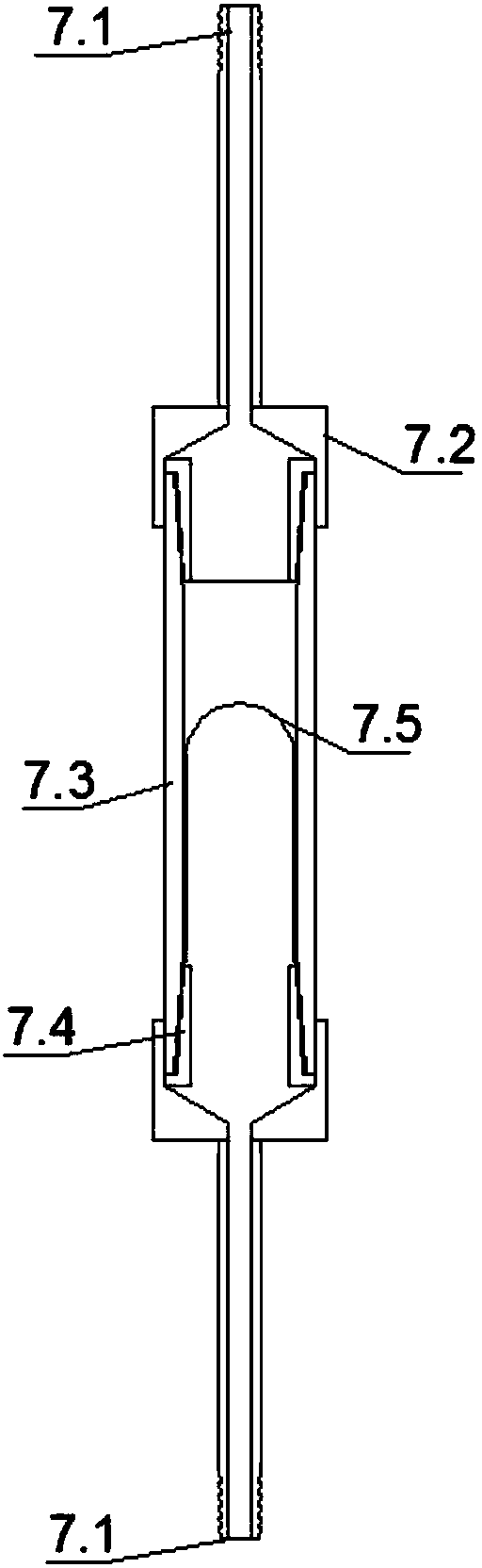

[0027] Such as figure 1 As shown, the present invention is a fast flame-retardant solid combustion particle sampling device, including a sleeve, a filter cartridge 7 and an air pump 8, and the sleeve includes an outer tube 1 and a cooling tube 2 that are sequentially sleeved from the outside to the inside. , flame retardant tube 3 and sampling tube 4, one end of the sleeve is the sampling end, a blocking plate 5 is provided at the end of the sampling end, and an annular plate 6 is provided at the other end of the sleeve, and the annular plate 6 is located at every two Between two adjacent pipe bodies, and the sampling pipe 4 communicates with the filter cartridge 7 and the air pump 8 in sequence, such as figure 2 As shown, the blocking plate 5 and the annular plate 6 respectively form interlayers between the outer pipe 1 and the cooling pipe 2, the cooling pipe 2 and the flame-retardant pipe 3, the flame-retardant pipe 3 and the sampling pipe 4, and the interlayers are divide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com