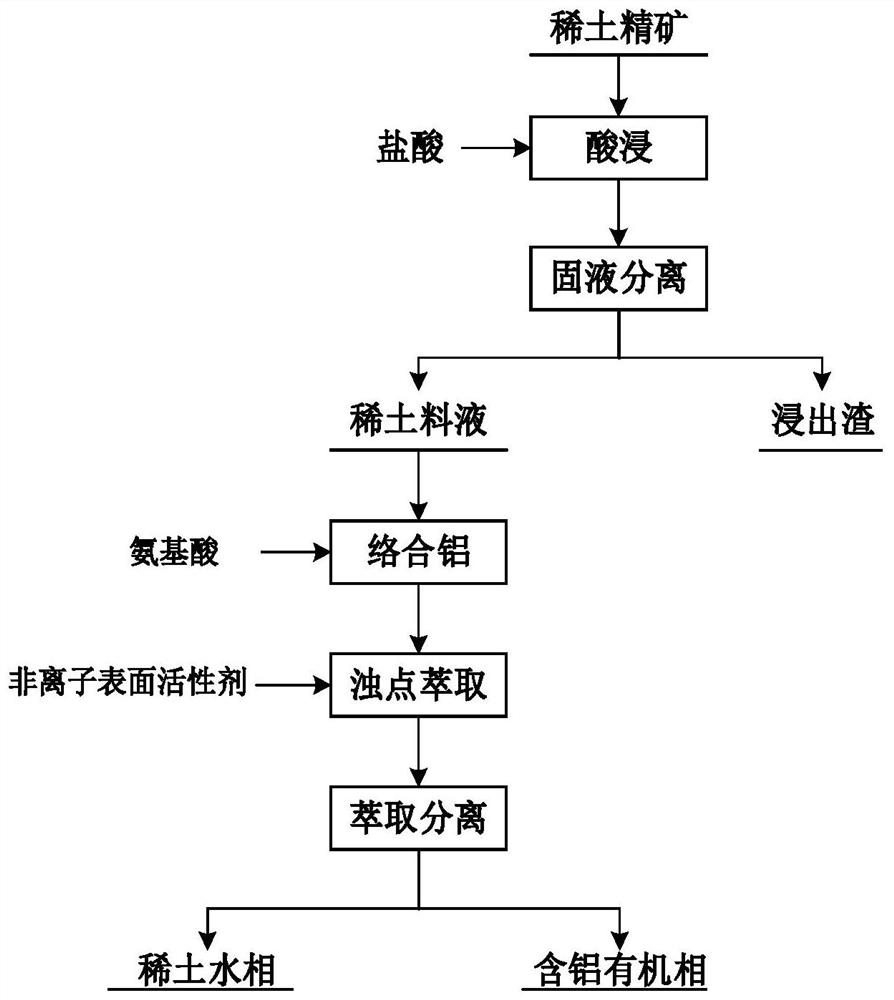

Method for removing aluminum from rare earth feed liquid through complexing-cloud point extraction

A technology of rare earth material liquid and cloud point, which is applied in the fields of materials, hydrometallurgy, and chemistry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0029] (1) Rare earth hydrochloric acid leaching solution: aluminum content 3.036g / L, rare earth content 5g / L, solution pH=0.5.

[0030] (2) Pipette 50mL of rare earth leaching solution into a 300mL conical flask, put it into a magnetic stirring constant temperature water bath, weigh 2.482g of glutamic acid, stir at a constant temperature at 40°C, and slowly add it to the conical flask. Slowly adjust the pH of the rare earth solution to 4.5 with ammonia-ammonium chloride buffer solution, continue to stir for 20 minutes, then add 10mL Triton X-114, keep the temperature at 40°C and stir for 10 minutes, then extract and separate phases, equilibrate for 10 minutes, extract and separate phases to obtain an aluminum-containing organic phase And the rare earth solution after removing aluminum, through the above operations, the primary extraction rate of aluminum is 78.01%, and the extraction rate of rare earth is 5.09%, realizing the separation of rare earth and aluminum.

specific Embodiment 2

[0032] (1) Rare earth hydrochloric acid leaching solution: aluminum content 1.745g / L, rare earth content 0.1g / L, solution pH=0.5.

[0033] (2) Pipette 50mL of rare earth leaching solution into a 300mL conical flask and put it into a magnetic stirring constant temperature water bath, weigh 1.4263g of glutamic acid, stir at a constant temperature at 40°C and slowly add it to the conical flask, and add it after the feeding is completed and stirred evenly Slowly adjust the pH of the rare earth solution to 4.5 with ammonia-ammonium chloride buffer solution, continue to stir for 20 minutes, add 10 mL of Triton X-114, keep the temperature at 35°C and stir for 10 minutes, then extract and separate phases. The equilibration time was 15 minutes, and the extraction and phase separation were carried out to obtain the aluminum-containing organic phase and the rare earth solution after removing aluminum. Through the above operations, the primary extraction rate of aluminum was 78.85%, and th...

specific Embodiment 3

[0035] (1) Rare earth hydrochloric acid leaching solution: aluminum content 3.036g / L, rare earth content 50g / L, solution pH=0.5.

[0036](2) Pipette 50mL of rare earth leaching solution into a 300mL conical flask and put it into a magnetically stirred constant temperature water bath, weigh 2.617g of histidine, stir at a constant temperature at 40°C and slowly add it to the conical flask, and add it after the feeding is completed and stirred evenly Slowly adjust the pH of the rare earth solution to 4.5 with ammonia-ammonium chloride buffer solution, continue to stir for 20 minutes, then add 10 mL of Triton X-114, keep the temperature at 50°C and stir for 10 minutes, then extract and separate phases. Equilibrium time is 20 minutes, extraction and phase separation are carried out to obtain an aluminum-containing organic phase and a rare earth solution after removing aluminum. Through the above operations, the primary extraction rate of aluminum is 70.85%, and the extraction rate o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com