Method and device for impurity removal and dehydration of waste engine oil by applying compound field force

A technology of compound field force and waste oil, which is applied in the fields of electric/magnetic dehydration/demulsification, dehydration/demulsification regulation/control, and processing of hydrocarbon oil, etc., which can solve problems such as economic loss and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

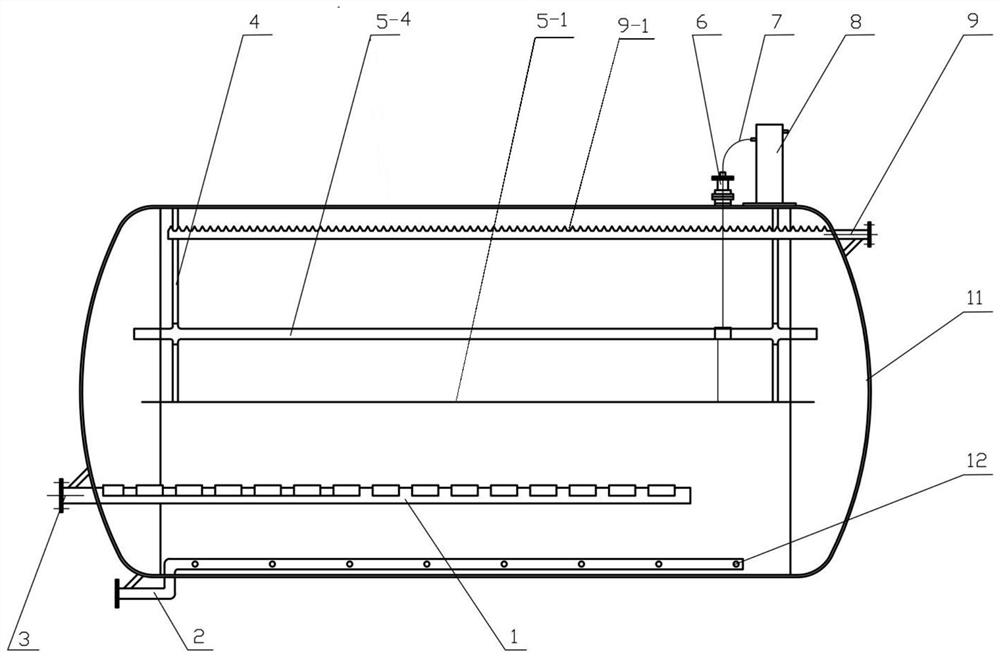

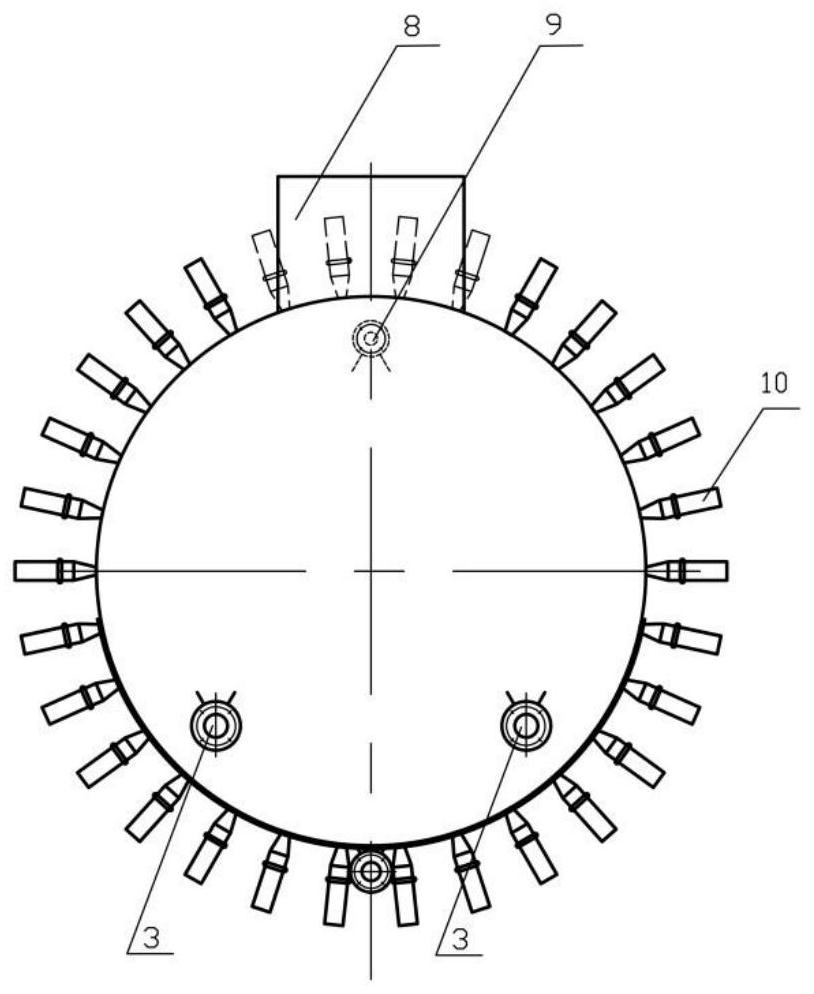

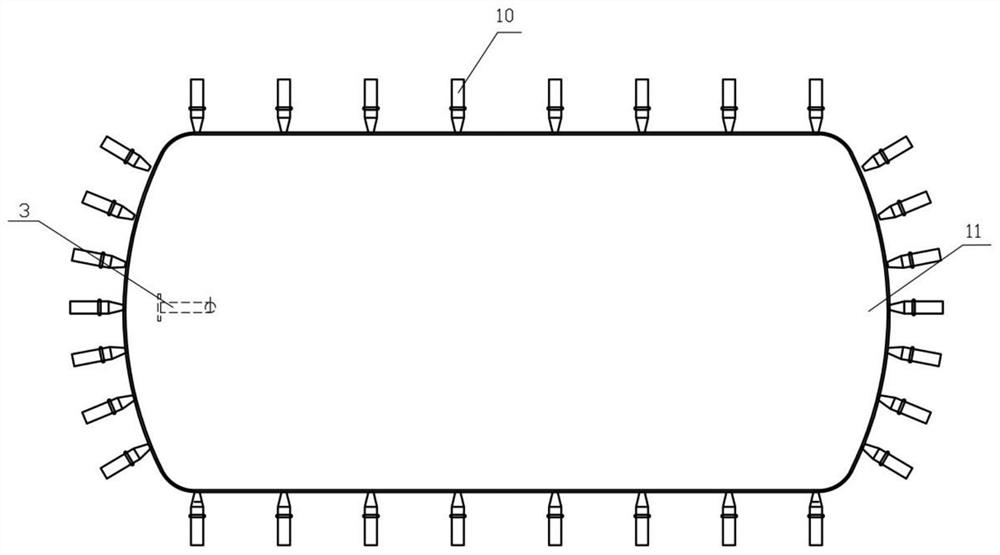

[0046] Such as figure 1 As shown, a device for removing impurities and dehydrating waste engine oil by applying compound field force, including: reaction tank 11, liquid distributor 1, drain pipe 2, seepage hole 12, liquid input pipe 3, insulating suspension plate 4, electrode plate , High-pressure introduction pipe 6, high-pressure connecting bellows 7, automatic frequency conversion voltage regulator 8, liquid output pipe 9 and ultrasonic generation pipe 10.

[0047] The reaction tank 11 adopts a horizontal 50m 3 Standard storage tanks are manufactured and processed in accordance with GB150-2011 "Pressure Vessels". The tank body should be insulated with thermal insulation materials, and the outer casing of the tank should be grounded for insulation treatment. The thermal insulation materials and insulation treatment methods are implemented in accordance with GB150-2011 "Pressure Vessels".

[0048] Drainage pipe 2 is arranged around the inner bottom of reaction tank 11, ado...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com