A kind of preparation method of tunable solid-state fluorescent carbon dots

A technology of solid-state fluorescence and carbon dots, applied in chemical instruments and methods, luminescent materials, nano-optics, etc., can solve the problems of complex synthesis process, low photoluminescence quantum yield, and increased synthesis cost, and achieve simple preparation methods, Convenient purification and convenient supply of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for preparing adjustable solid-state fluorescent carbon dots for LEDs, the steps of which are:

[0036] (1) Add 0.15 mmol of dithiosalicylic acid to 10 mL of saturated acetic acid aqueous solution (36 wt.%), and ultrasonically mix for 10 minutes;

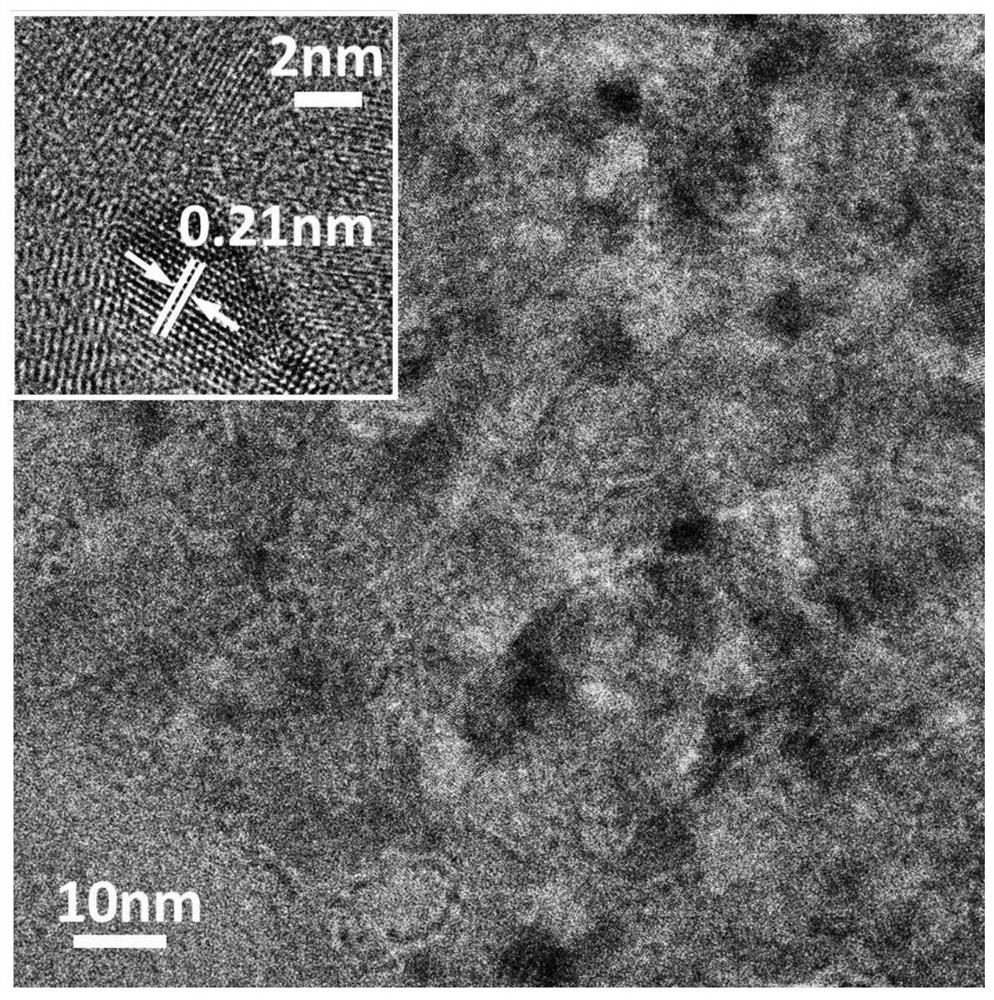

[0037] (2) Transfer the sonicated solution into a 50mL and tetrafluoroethylene liner, react in the reactor at 180°C for 15h, cool down to room temperature naturally after the reaction, add deionized water into the reacted solution, and the solution becomes cloudy rapidly , the turbid solution was centrifuged at a speed of 6500 rad / min for 10 minutes, and the supernatant was removed to obtain a precipitate. Repeat this process 2-3 times to obtain purified carbon dots. The purified carbon dot precipitate mixed with a small amount of solution was frozen in a refrigerator at -20°C until the solution became solid, and the solid was placed in a freeze dryer for 24 hours to obtain dry carbon dot powder.

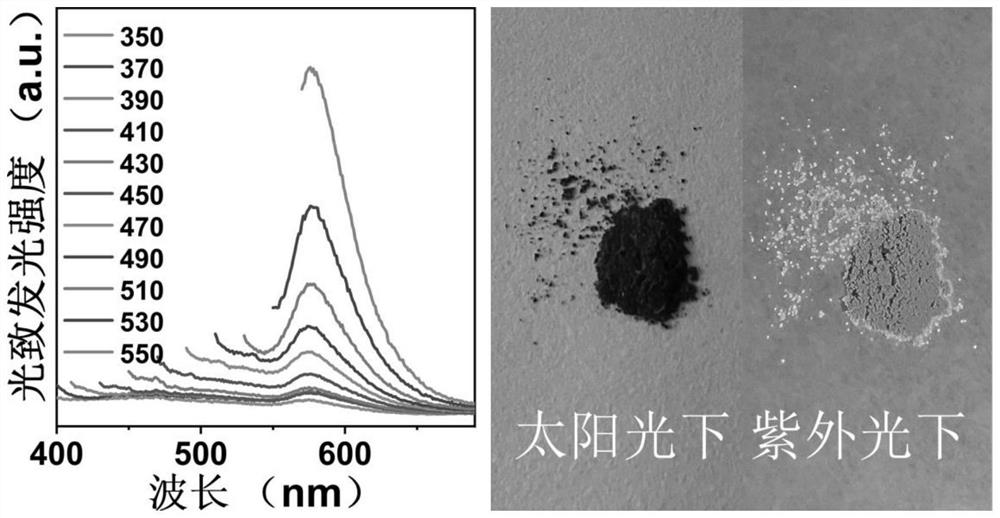

[0038] (3) Dispe...

Embodiment 2

[0040] (1) Add 0.5 mmol of dithiosalicylic acid to 10 mL of saturated aqueous acetic acid solution (36 wt.%), and ultrasonically mix for 10 minutes;

[0041] (2) Transfer the sonicated solution into a 50mL and tetrafluoroethylene liner, react in the reactor at 180°C for 15h, cool down to room temperature naturally after the reaction, add deionized water into the reacted solution, and the solution becomes cloudy rapidly , the turbid solution was centrifuged at a speed of 6500 rad / min for 10 minutes, and the supernatant was removed to obtain a precipitate. Repeat this process 2-3 times to obtain purified carbon dots. The purified carbon dot precipitate mixed with a small amount of solution was frozen in a refrigerator at -20°C until the solution became solid, and the solid was placed in a freeze dryer for 24 hours to obtain dry carbon dot powder.

[0042] (3) Disperse 0.2 g of the purified carbon dots in 3 mL of toluene solution mixed with 1 g of polystyrene, and stir at 60° C....

Embodiment 3

[0044] (1) Add 1 mmol of dithiosalicylic acid to 10 mL of saturated aqueous acetic acid solution (36 wt.%), and ultrasonically mix for 10 minutes;

[0045](2) Transfer the sonicated solution into a 50mL and tetrafluoroethylene liner, react in the reactor at 180°C for 15h, cool down to room temperature naturally after the reaction, add deionized water into the reacted solution, and the solution becomes cloudy rapidly , the turbid solution was centrifuged at a speed of 6500 rad / min for 10 minutes, and the supernatant was removed to obtain a precipitate. Repeat this process 2-3 times to obtain purified carbon dots. The purified carbon dot precipitate mixed with a small amount of solution was frozen in a refrigerator at -20°C until the solution became solid, and the solid was placed in a freeze dryer for 24 hours to obtain dry carbon dot powder.

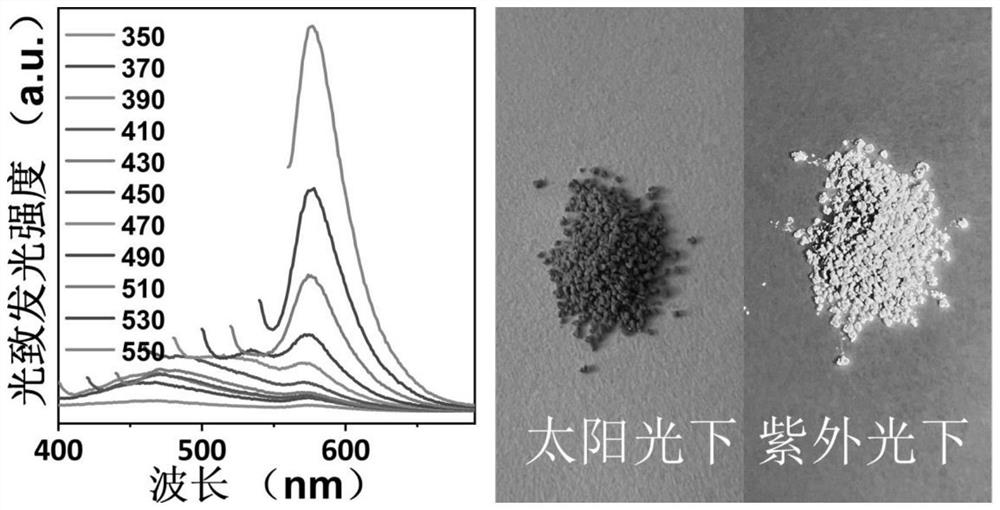

[0046] (3) Disperse 0.2 g of the purified carbon dots in 3 mL of toluene solution mixed with 1 g of polystyrene, and stir at 60° C. fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com