Method for characterizing short-cut nitrification and denitrification stability of sewage based on SOUR online detection

A short-range nitrification and denitrification technology, applied in chemical instruments and methods, test water, biological water/sewage treatment, etc., can solve problems such as changes in the performance of sewage treatment processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

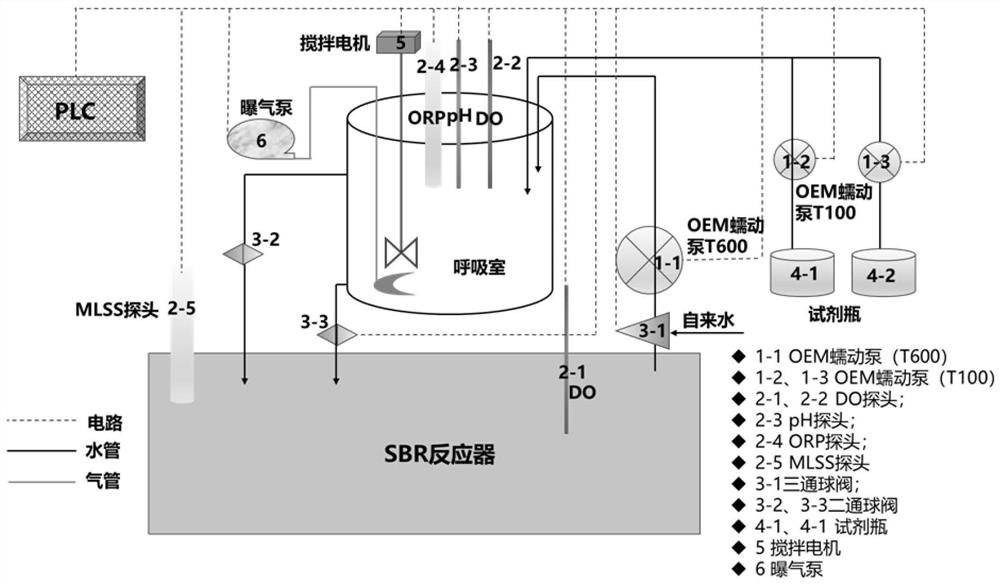

[0065] Embodiment 1SOUR on-line continuous detection characterizes microbial activity

[0066] 1. Use SBR reactor to treat synthetic wastewater, and add culture medium to the reactor to obtain synthetic wastewater. Specifically: In the SBR reactor, add medium and activated sludge, the concentration of activated sludge is 3500-6000mg / L; the formula of the medium is: ammonia nitrogen 30mg / L, COD 210mg / L, inorganic salt medium. The way of adding the culture medium is: slowly adding the culture medium during the water inlet process in each reaction cycle of each stage, so, after each cycle of each stage, when entering the next cycle, the feed water in the reaction chamber The water is synthetic waste water (medium will be added).

[0067] Wherein, the formula of inorganic salt medium is: Na 2 HPO 4 12H 2 O 1000mg / L, KH 2 PO 4 1000mg / L, (NH 4 ) 2 SO 4 300mg / L, MgSO 4 ·7H 2 O 250mg / L, trace elements 5.0mL / L.

[0068] The formula of trace elements is: EDTA 0.5g / L, ZnSO ...

Embodiment 2A

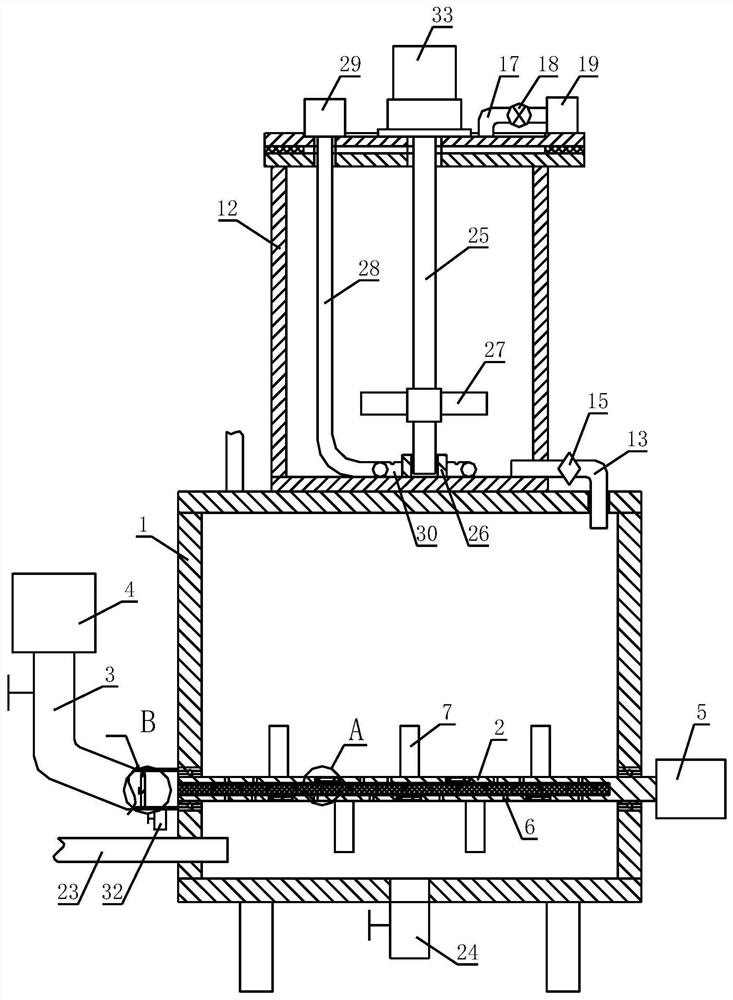

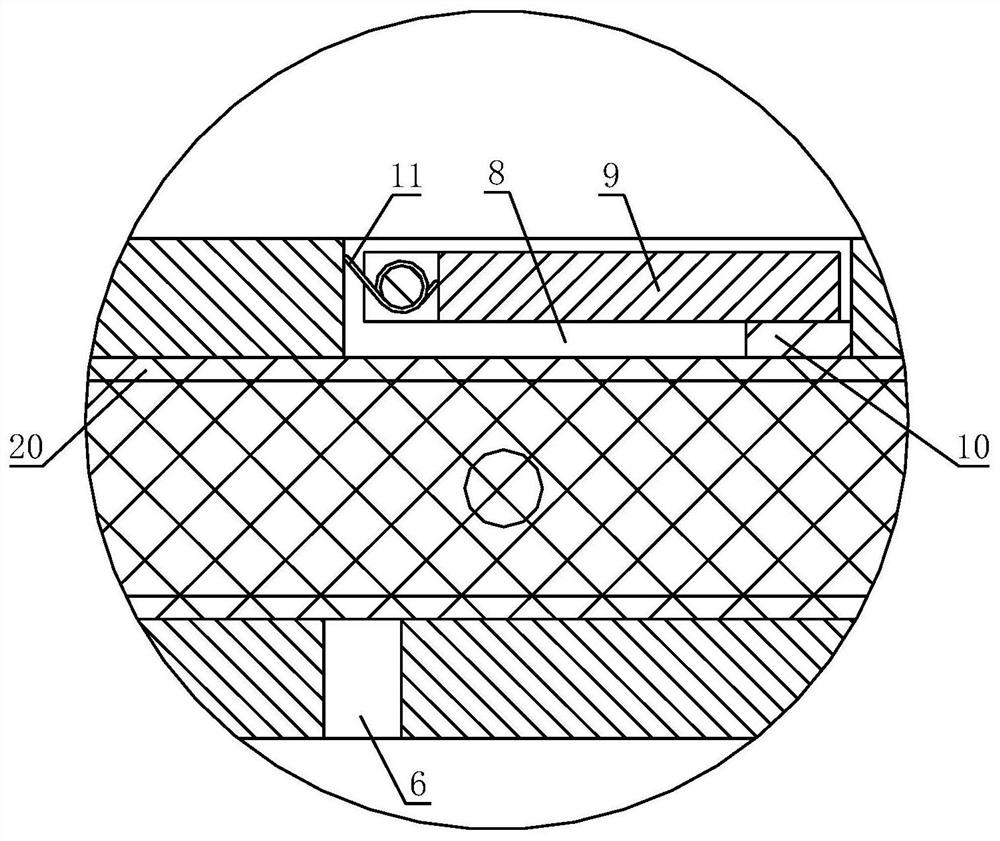

[0082] The SOUR detection of embodiment 2AOB, NOB

[0083] In the SBR reactor, the aerobic operation is about 30 minutes, and the mud-water mixture in the SBR reactor is pumped into the breathing chamber. The volume of the breathing chamber is 2L. At this time, close the two-way ball valve on the overflow pipe to prevent the mud-water mixture from flowing to In the reaction chamber; turn on the stirring motor and the aeration pump, aerate until the DO rises to 8mg / L, stop the aeration and seal it, and automatically add sodium chlorate solution when the DO drops to 6mg / L to make the concentration in the mixed solution be 0.02mol / L; when DO drops to 4mg / L, allylthiourea is automatically added to make the concentration in the mixture 20mg / L, and the measurement is continued until DO drops to 0mg / L. This process is an intermittent online detection. During this process, the breathing chamber is aerated until the DO reaches mg / L and stops. The timing of the detection is: during the...

Embodiment 3

[0087] Embodiment 3 Ammonia oxidation, nitrite oxidation rate detection

[0088] The activated sludge samples in the whole stage, commissioning stage and short stage of the SBR reactor were taken, washed three times with distilled water, and shake flask experiments were used to investigate the ammonia oxidation rate and nitrite oxidation rate of the active samples in each stage. The amount of activated sludge inoculum at different stages was 20%, the shaking table speed was controlled at 120rpm, and the temperature was 25°C. Water samples were taken for 0h, 1h, and 3h to detect the concentration of ammonia nitrogen and nitrite. The results are shown in Table 5 below.

[0089] Table 5 Ammonia nitrogen concentration and nitrite concentration in different time periods

[0090]

[0091] As shown in the table, during the full nitrification stage, the ammonia oxidation rate (SAOR) and nitrite oxidation rate (SNOR) of the activated sludge were 1.37mg / L / h and 1.80mg / L / h respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com