Modification method of all-silicon Beta molecular sieve containing three-membered ring

A technology of molecular sieves and three-membered rings, which is applied in molecular sieve catalysts, chemical instruments and methods, organic chemistry, etc., can solve problems such as unfavorable environmental protection, ungreen synthesis process, and inability to achieve green environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

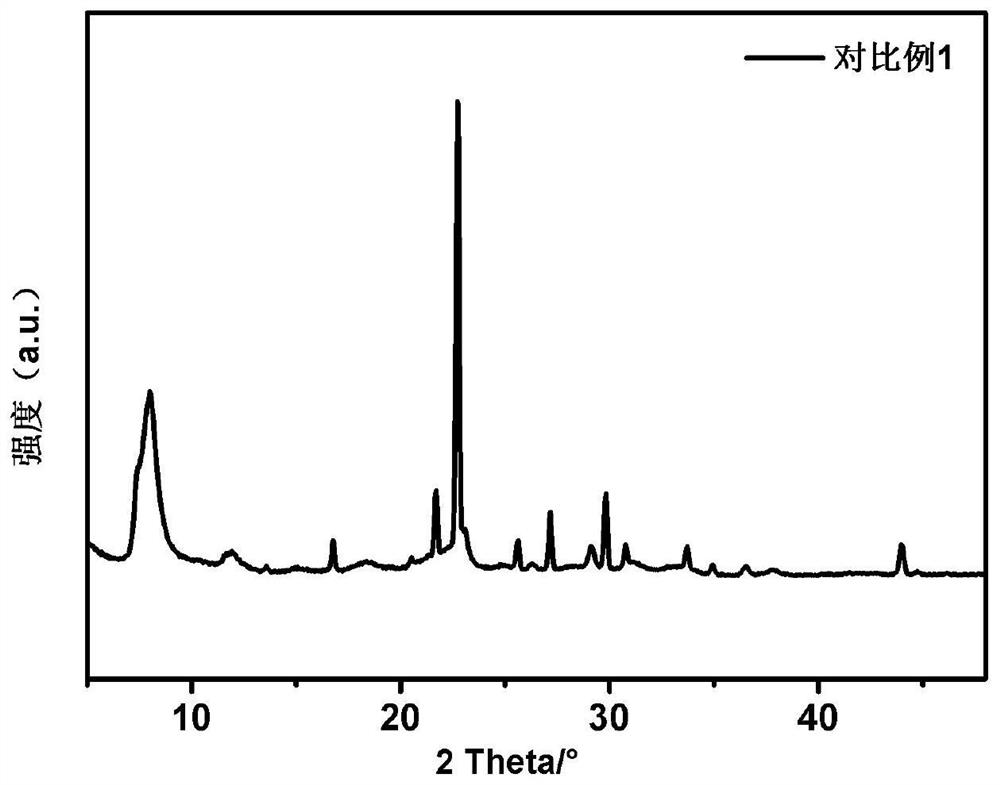

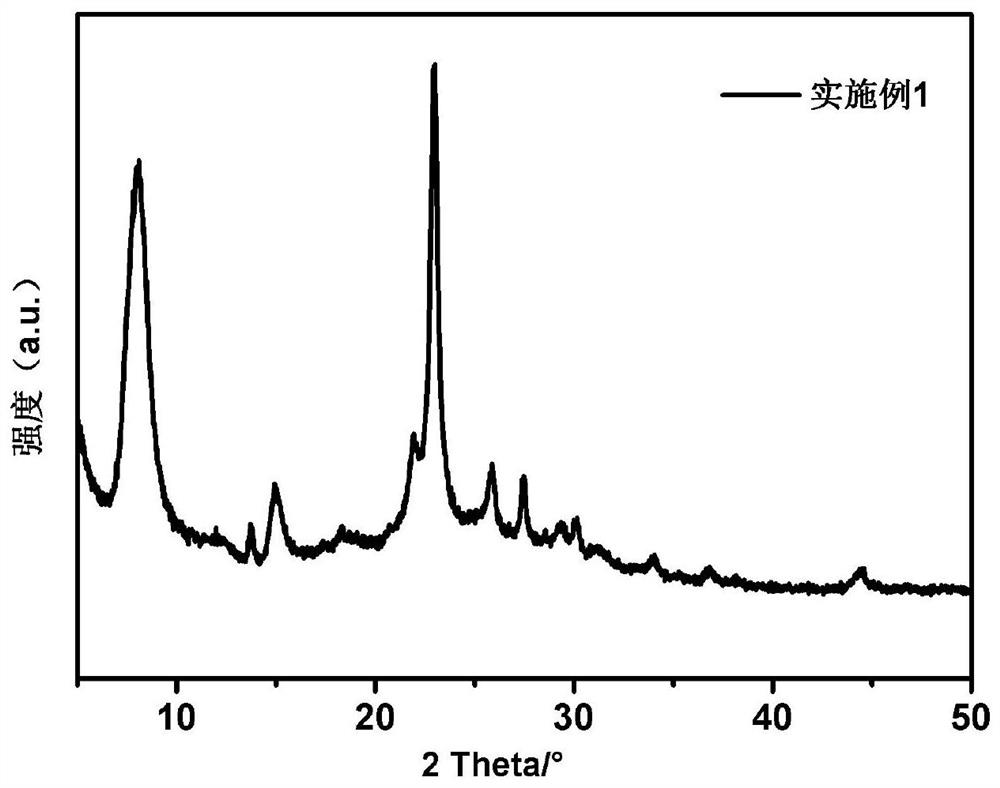

[0046] Such as figure 2 As shown, take 630 grams of nitric acid (mass fraction 65%-68%) and place it in a 500ml volumetric flask, then use deionized water to make up to 500ml to obtain a nitric acid solution, which is designated as A solution. Weigh 25g of Beta molecular sieve powder (Si / Al=10.6) and mix it with A solution evenly and transfer it to a round bottom flask. Place the round bottom flask in an oil bath and heat it through the oil bath at a temperature of 100°C. The heating rate is 1°C / min, the heating time is 12 hours, the magnet is placed at the bottom of the round bottom flask for stirring, and the outlet of the top of the round bottom flask is equipped with a serpentine condenser for condensation and reflux, and the dealuminated modified all-silicon Beta molecular sieve Si- Beta. The Si-Beta was washed several times with deionized water until the supernatant obtained after centrifugation had pH ≈ 7. The washed Si-Beta molecular sieves were placed in an oven an...

Embodiment 2

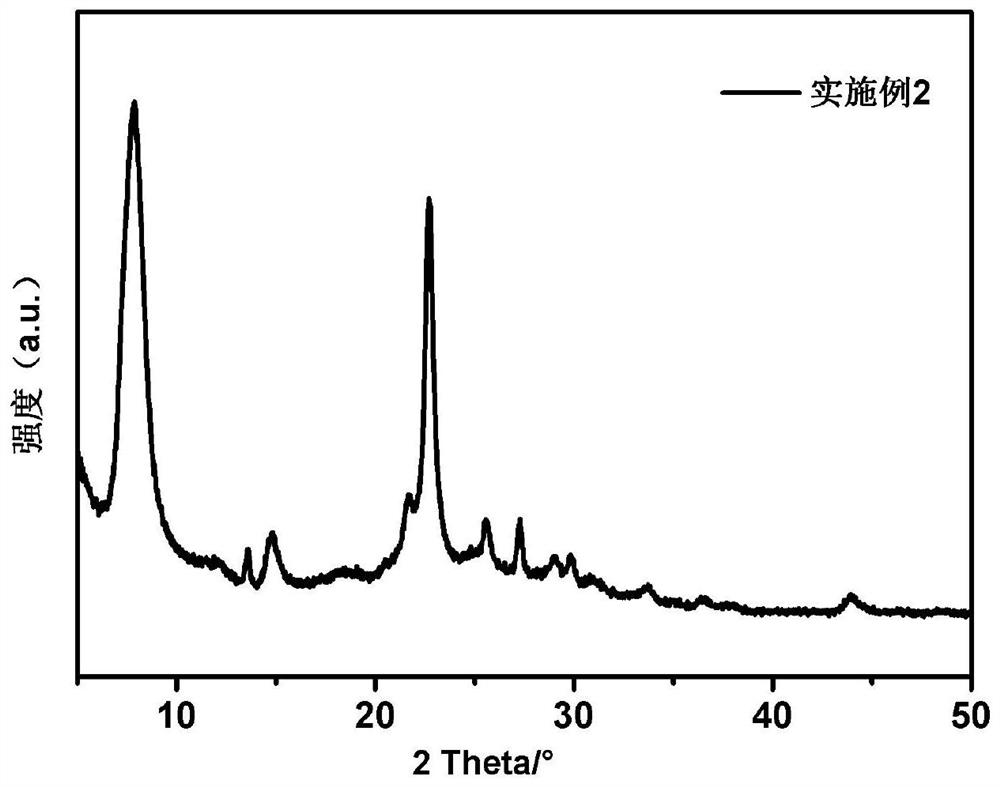

[0048] Such as image 3 As shown, take 630 grams of nitric acid (mass fraction 65%-68%) and place it in a 500ml volumetric flask, then use deionized water to make up to 500ml to obtain a nitric acid solution, which is designated as A solution. Weigh 25g of Beta molecular sieve raw powder (Si / Al=10.6) and mix it evenly with solution A, then transfer it to a round bottom flask, place the round bottom flask in an oil bath, and heat it through the oil bath at a temperature of 100°C , the heating rate is 1°C / min, the heating time is 12 hours, the magnet is placed at the bottom of the round bottom flask for stirring, and the outlet of the top of the round bottom flask is equipped with a serpentine condenser for condensing and reflux, that is, the dealuminated modified all-silicon Beta molecular sieve Si -Beta. The Si-Beta was washed several times with deionized water until the supernatant obtained after centrifugation had pH ≈ 7. The washed Si-Beta molecular sieves were placed in ...

Embodiment 3

[0050] if Figure 4 As shown, take 630 grams of nitric acid (mass fraction 65%-68%) and place it in a 500ml volumetric flask, then use deionized water to make up to 500ml to obtain a nitric acid solution, which is designated as A solution. Weigh 25g of Beta molecular sieve raw powder (Si / Al=10.6) and mix it evenly with solution A, then transfer it to a round bottom flask, place the round bottom flask in an oil bath, and heat it through the oil bath at a temperature of 100°C , the heating rate is 1°C / min, the heating time is 12 hours, the magnet is placed at the bottom of the round bottom flask for stirring, and the outlet of the top of the round bottom flask is equipped with a serpentine condenser for condensing and reflux, that is, the dealuminated modified all-silicon Beta molecular sieve Si -Beta. The Si-Beta was washed several times with deionized water until the supernatant obtained after centrifugation had pH ≈ 7. The washed Si-Beta molecular sieves were placed in an o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com