Processing technology of die casting and its cutting system

A technology of processing technology and cutting system, which is applied in the direction of metal processing equipment, manufacturing tools, abrasive jet machine tools, etc., can solve the problems of poor cutting accuracy, achieve the effects of ensuring cutting accuracy, stable width, and improving cutting accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

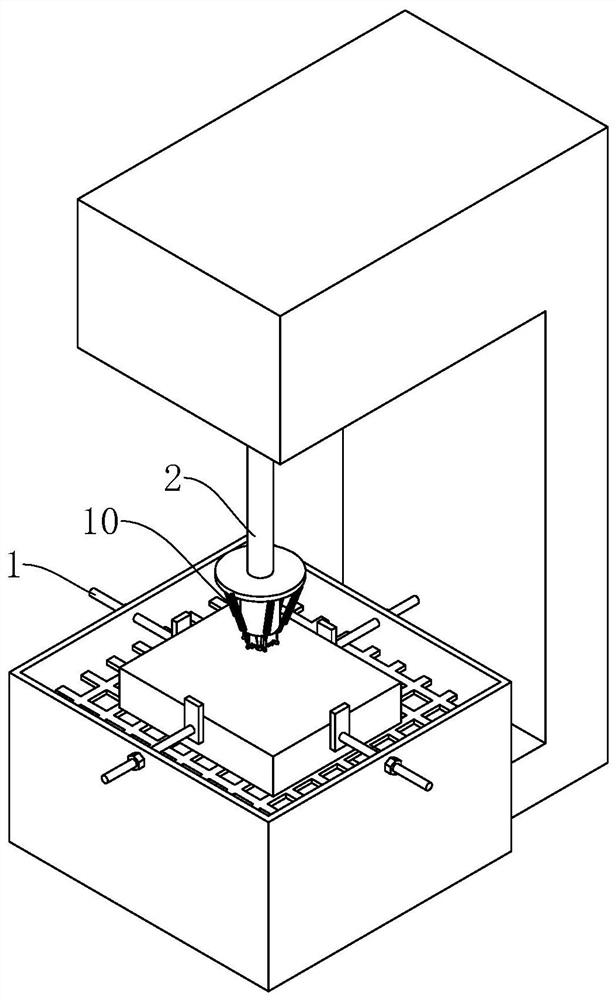

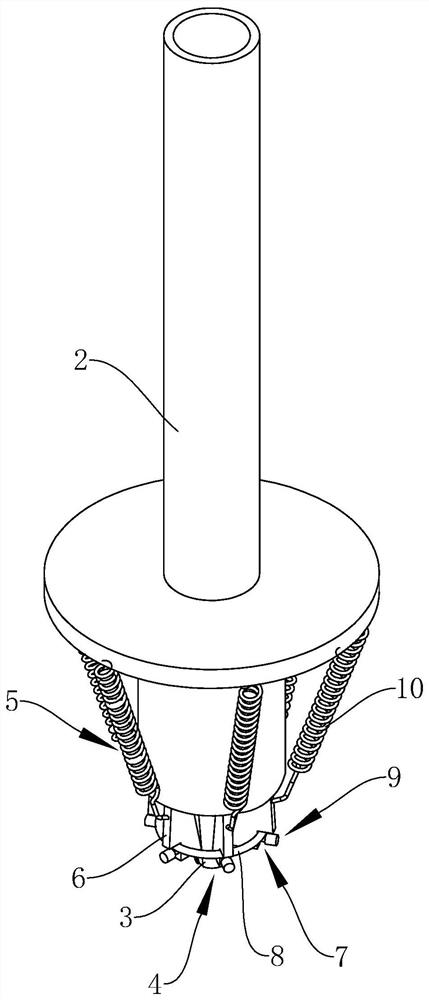

[0043] Attached to the following Figure 1-5 This application will be described in further detail.

[0044] The embodiments of the present application disclose a processing technology and a cutting system of a die casting.

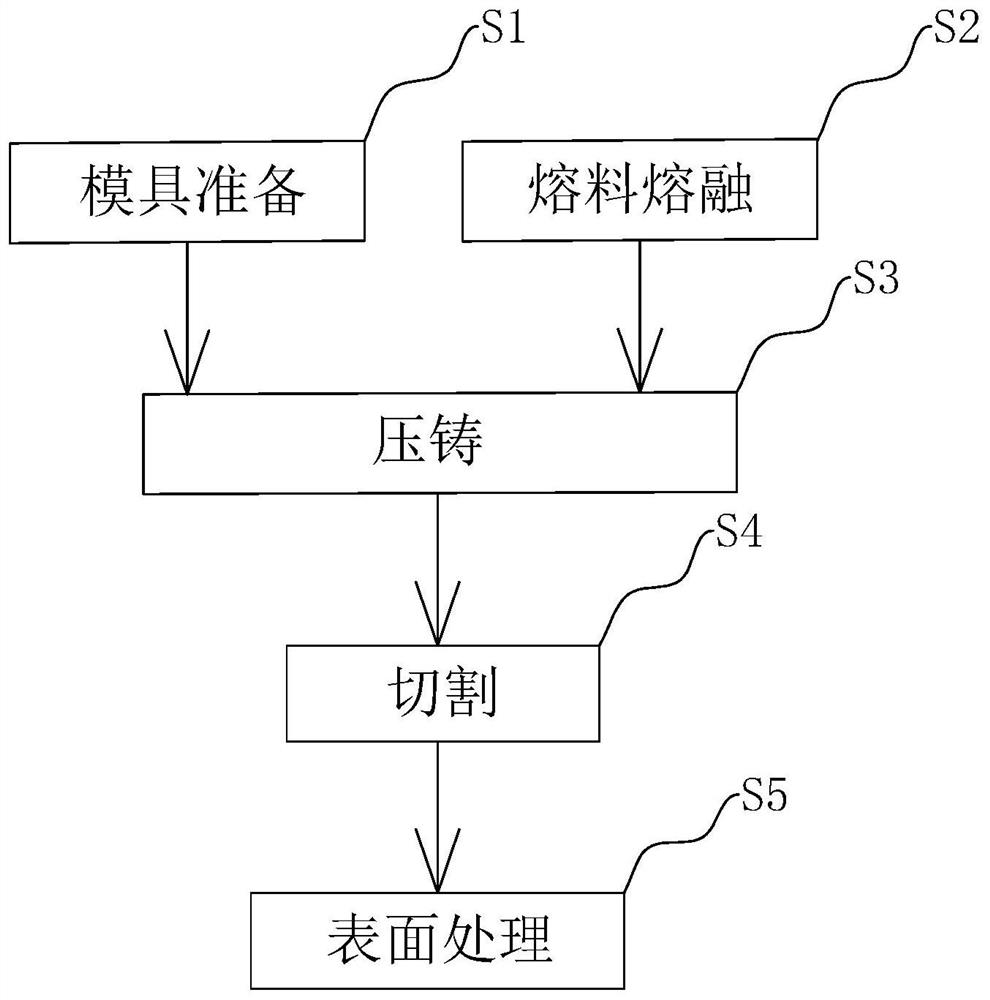

[0045] refer to figure 1 , a processing technology of a die casting includes the following steps:

[0046] S1. Mold preparation process, replace the matching mold, preheat the mold and spray mold release agent;

[0047] S2. molten material melting process, use melting furnace to melt solid metal to obtain liquid metal;

[0048] S3. Die-casting process, the mold in step S1 is evacuated to form a negative pressure in the mold, the liquid metal obtained in step S2 is absorbed into the mold under the communication of the injection tube, and the cavity in the mold is completely Filling, the mold is die-casting the liquid metal to obtain a die-casting part;

[0049] S4. In the cutting process, the die-casting parts are removed from the mold, and the die-cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com