Intelligent storage spraying device for electrostatic spraying

An electrostatic spraying and spraying device technology, which is applied to spraying devices, spraying discharge devices and other directions, can solve the problems of limited use of spray guns, inconvenient use, and inconvenience to carry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

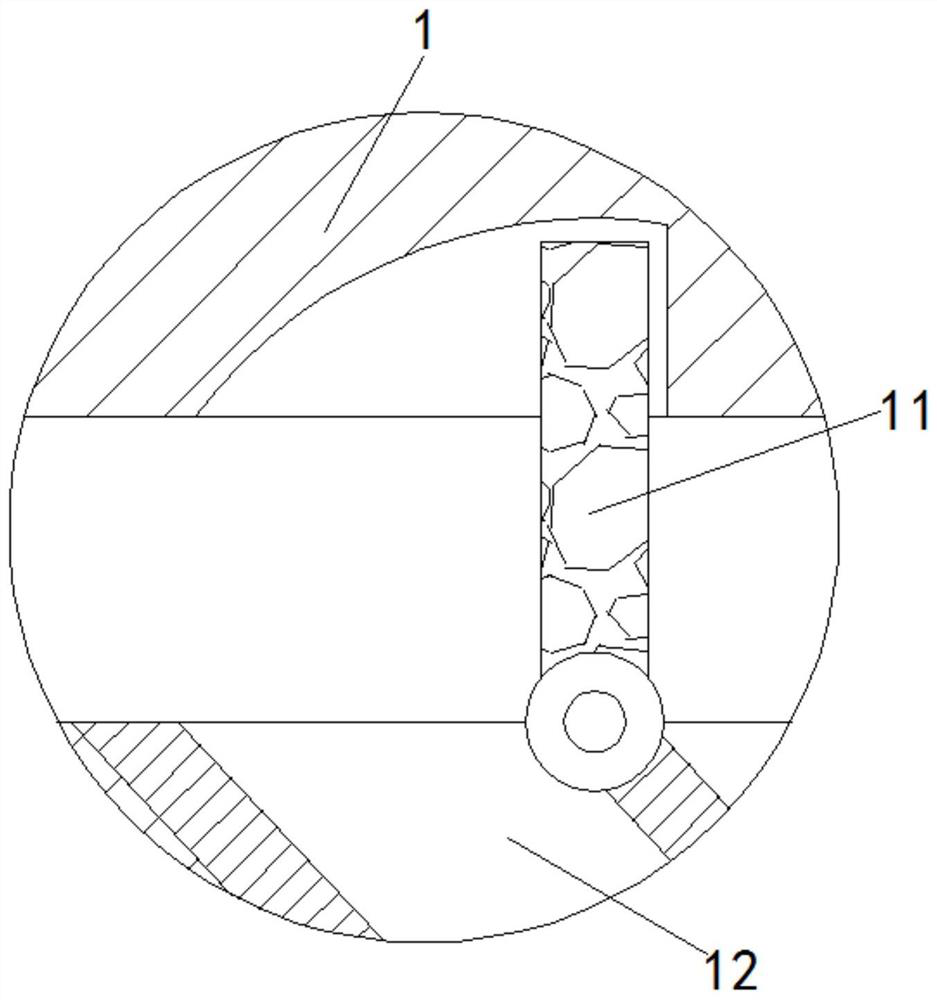

[0029] see Figure 1-3 , an intelligent storage and injection device for electrostatic spraying, including a spray gun 1, an air pressure mechanism 2 is inserted on the right side of the spray gun 1, a storage mechanism 3 is inserted on the top of the spray gun 1, and the left side of the storage mechanism 3 is fixed A backup power supply 4 is connected, the top of the spray gun 1 is fixedly connected with a sliding rheostat 5, the top of the sliding rheostat 5 is slidably connected with an adjusting piece 6, the top of the spray gun 1 is clamped with a knob 7, and the knob 7 is connected to the adjusting piece 6 through a pull cord , so that the knob 7 can drive the adjustment plate 6 to rotate, the bottom of the knob 7 is slidably connected with a rotating shaft 8, the outer side of the rotating shaft 8 is sleeved with a reel 9, the inner wall of the reel 9 is hinged with a buffer claw 10, and the inner wall of the spray gun 1 is hinged with a pendulum The plate 11 and the b...

Embodiment 2

[0031] see Figure 1-4 , an intelligent storage injection device for electrostatic spraying, comprising a spray gun 1, the right side of the spray gun 1 is plugged with an air pressure mechanism 2, the left side of the air pressure mechanism 2 is fixedly connected with an interface 21, and the interface 21 is threaded on the side of the spray gun 1 On the right side, it is convenient to fix the air pressure mechanism 2. The left side of the interface 21 is clamped with a transmission wheel 22. The right side of the transmission wheel 22 is welded with a screw 23. The outer thread of the screw 23 is connected with a slider 24, and the slider 24 is slidably connected to the interface. 21, ensure that the slide block 24 will not rotate with the screw rod 23, the right side of the slide block 24 is hinged with a push rod 25, the right side of the push rod 25 is hinged with an air valve 26, the drive wheel 22 drives the screw rod 23 to rotate, and the screw rod 23 Drive the slider ...

Embodiment 3

[0033] see Figure 1-6, an intelligent storage and injection device for electrostatic spraying, including a spray gun 1, an air pressure mechanism 2 is inserted on the right side of the spray gun 1, a storage mechanism 3 is inserted on the top of the spray gun 1, and the right side of the storage mechanism 3 is fixed Connected with a scale plate 31, the bottom of the material storage mechanism 3 is plugged with a material tube 32, the inside of the material tube 32 is fixedly connected with a discharge wheel 33, the back of the discharge wheel 33 is engaged with a transmission rod 34, and the front of the transmission rod 34 is engaged with a Adjusting rod 35, the outer thread of adjusting rod 35 is connected with regulating plate 36, and the inside of regulating plate 36 is provided with material hole, and material hole restricts baffle plate 37 to swing upwards, and simultaneously material hole passes the feeding material on the top of material storage mechanism 3 through hos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com