Flexible single-electrode friction nano generator

A nano-generator and single-electrode technology, which is applied in the direction of friction generators, etc., can solve problems affecting stability and durability, and achieve the effect of low cost, simple method and strong conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

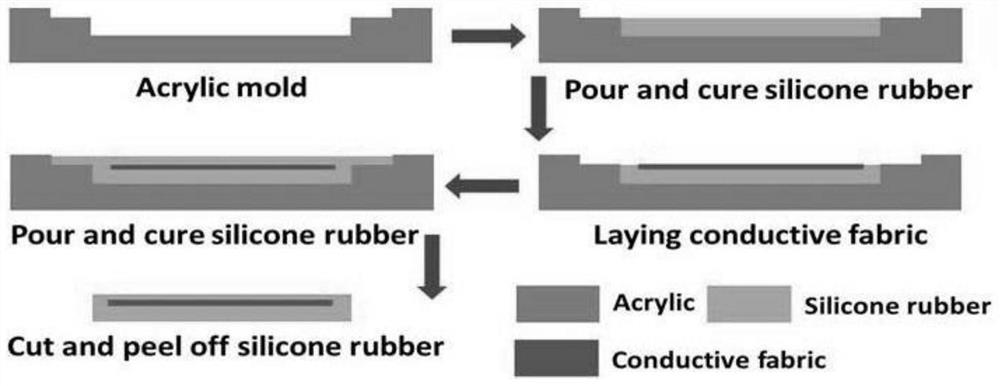

[0040] 1) Take an appropriate amount of liquid silica gel and propyl orthosilicate curing agent (the volume ratio of liquid silica gel and curing agent is 100:2.5), stir evenly in one direction with a glass rod; inject the liquid silica gel into the concave of the first step of the acrylic mold In a groove (55x115mm), wait for the silicone to fully cure at room temperature to obtain a silicone layer with a thickness of about 2.5mm.

[0041] 2) Take a flexible conductive cloth of a certain length and width, cut it into the desired shape (40x100mm), and spread it on the first layer of silicone sheet. A small tail should be left out of the conductive cloth to expose the silicone sheet, which is convenient for connecting wires later.

[0042] 3) Take an appropriate amount of liquid silica gel and propyl orthosilicate curing agent (the volume ratio of liquid silica gel and curing agent is 100:2.5), stir evenly in one direction with a glass rod; inject the liquid silica gel into the...

Embodiment 2

[0045] 1) Take an appropriate amount of liquid silica gel and propyl orthosilicate curing agent (the volume ratio of liquid silica gel and curing agent is 100:2.5), stir evenly in one direction with a glass rod; inject the liquid silica gel into the concave of the first step of the acrylic mold In a groove (55x90mm), wait for the silicone to fully cure at room temperature to obtain a silicone layer with a thickness of about 2.5mm.

[0046] 2) Take a flexible conductive cloth of a certain length and width, cut it into the desired shape (40x75mm), and spread it on the first layer of silicone sheet. A small tail should be left out of the conductive cloth to expose the silicone sheet, which is convenient for connecting wires later.

[0047] 3) Take an appropriate amount of liquid silica gel and propyl orthosilicate curing agent (the volume ratio of liquid silica gel and curing agent is 100:2.5), stir evenly in one direction with a glass rod; inject the liquid silica gel into the c...

Embodiment 3

[0050] 1) Take an appropriate amount of liquid silica gel and propyl orthosilicate curing agent (the volume ratio of liquid silica gel and curing agent is 100:2.5), stir evenly in one direction with a glass rod; inject the liquid silica gel into the concave of the first step of the acrylic mold In a groove (55x65mm), wait for the silicone to fully cure at room temperature to obtain a silicone layer with a thickness of about 2.5mm.

[0051] 2) Take a flexible conductive cloth of a certain length and width, cut it into the desired shape (40x50mm), and spread it on the first layer of silicone sheet. A small tail should be left out of the conductive cloth to expose the silicone sheet, which is convenient for connecting wires later.

[0052] 3) Take an appropriate amount of liquid silica gel and propyl orthosilicate curing agent (the volume ratio of liquid silica gel and curing agent is 100:2.5), stir evenly in one direction with a glass rod; inject the liquid silica gel into the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com