Block type stator forming method under full-size control, block type stator and motor

A full-scale, stator technology, used in the manufacture of stator/rotor bodies, manufacturing tools, electric components, etc., can solve problems such as the inability to align the stator and rotor cores of motors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

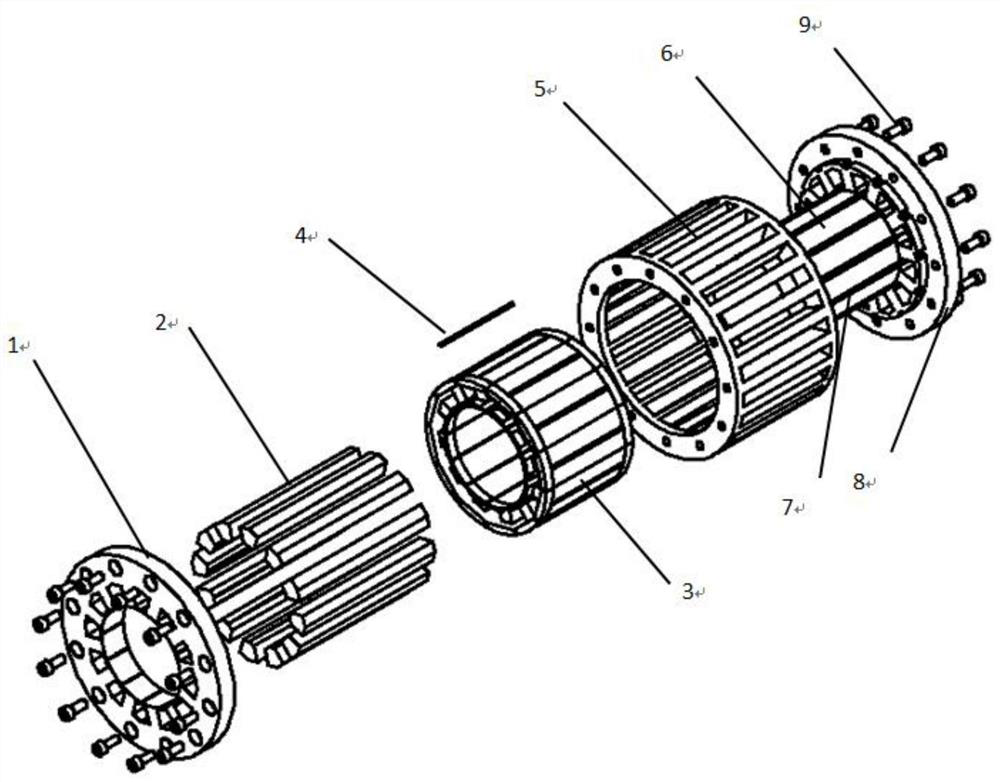

[0064] A method for forming a segmented stator under full-scale control, which includes a set of tooling used in two processes of stator core forming and welding and its use method, as follows:

[0065] The tooling includes a mandrel, a notch positioning rod, a toothed positioning rod, an upper pressing plate, a lower pressing plate, a screw and an outer ring fixing hoop. The outer ring fixing hoop is composed of upper, middle, and lower parts. Only the upper and lower parts are used for the round fixing hoop, and the upper, middle and lower parts are used for the outer round fixing hoop in the stator core welding process.

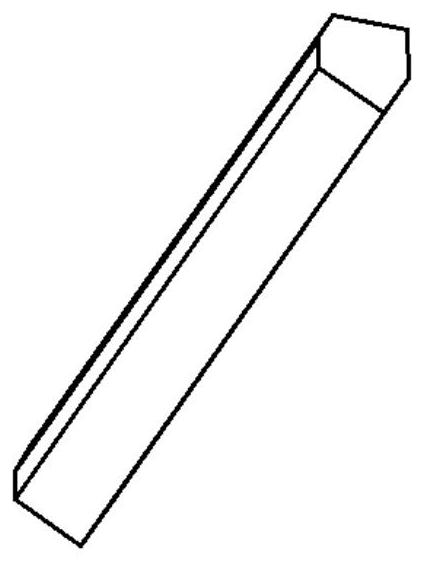

[0066] Press the notch positioning rod into the mandrel, and then match the two with the inner circle part of the lower pressing plate; then insert the toothed positioning rod into the corresponding position of the lower pressing plate.

[0067] Put the laminated stator core into the position corresponding to the tooling in step 2.

[0068] Install the ou...

Embodiment 2

[0074] The invention relates to an iron core shaping method, which realizes the full-scale control of the shape and position tolerance of the iron core through the cooperation of the laminated stator iron core and various parts of the tooling.

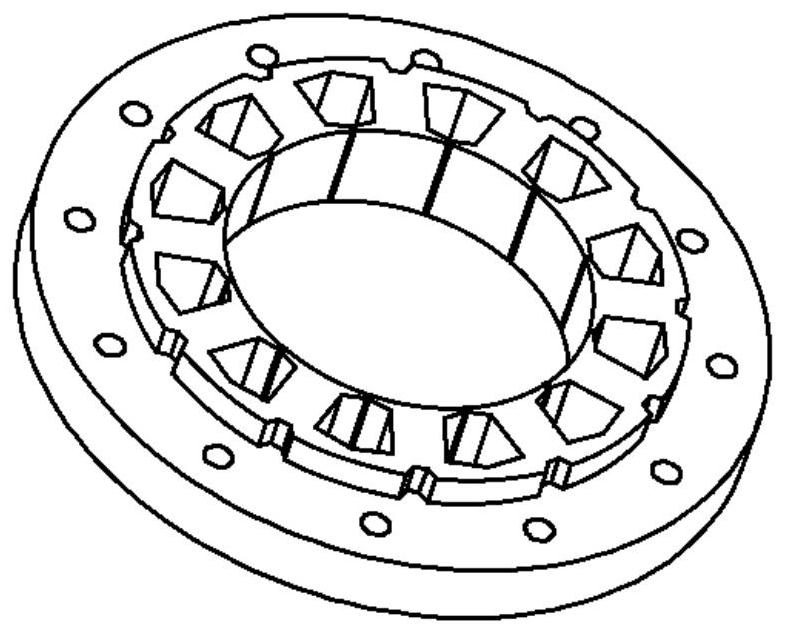

[0075] The method of lamination and shaping of the stator core, through the cooperation of the V-shaped buckle and the tooling, the size is shaped, which is convenient for the installation of the skeleton, and can ensure that the size error of the iron core meets the expected requirements after the winding of the stator is completed.

[0076] One set of tooling is used for two processes, in which the outer circle positioning hoop of tooling 5 adopts a three-section block structure. With the cooperation of other parts of the tooling, the full-size positioning of several iron core blocks can be carried out. The V-shaped buckle is put into the corresponding position in the middle of the stator core from the gap in the middle of the positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com