A grid spring and positioning grid with improved anti-abrasion performance and reduced resistance

A positioning grid and performance technology, applied in the direction of nuclear power generation, greenhouse gas reduction, climate sustainability, etc., to achieve the effect of improving abrasive performance, increasing contact area, and reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

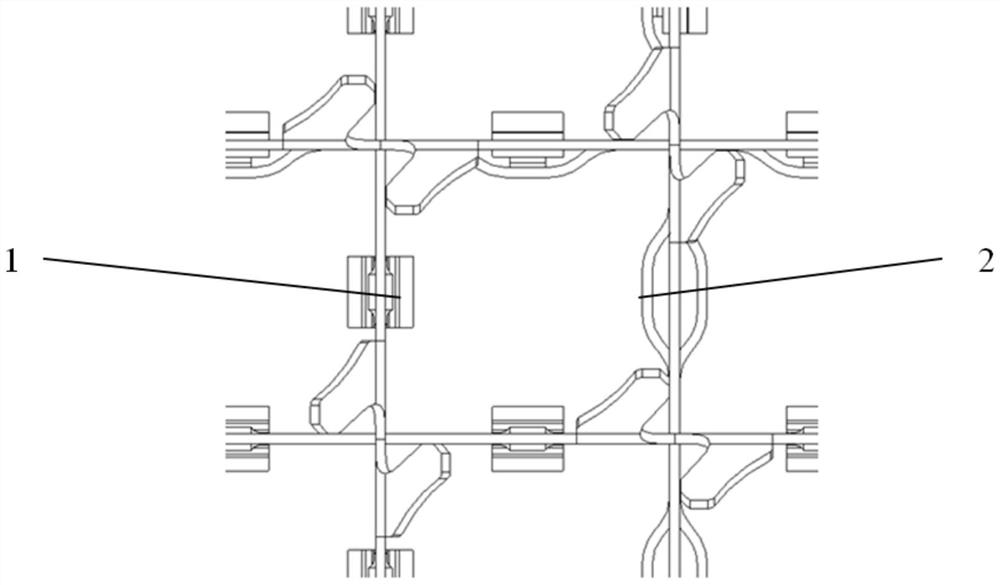

[0035] In the positioning grid cell, such as figure 1 As shown, the clamping structure is formed by the spring 1 and the opposite rigid protrusion 2, which jointly exert positive pressure on the fuel rods. The cell structure is used to achieve radial positioning of the fuel rods, and at the same time, the static friction is used to achieve axial restraint on the fuel rods.

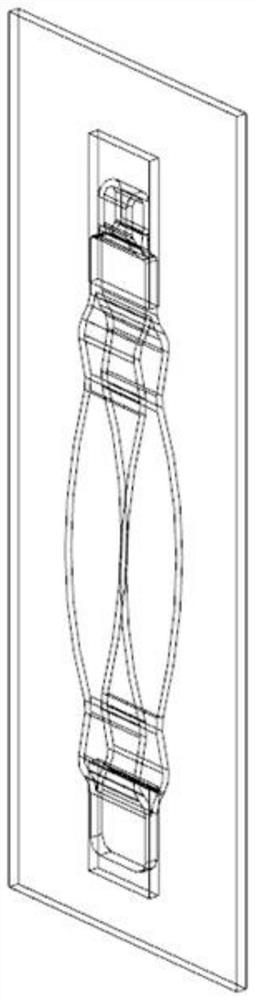

[0036] Such as figure 2 The AFA3G spacer grid spring shown is a separate spring bar, which is compressed to generate elastic force on the fuel rods by using the three-bend arch structure. The spring structure greatly hinders the coolant flow channel and increases the overall resistance of the grid.

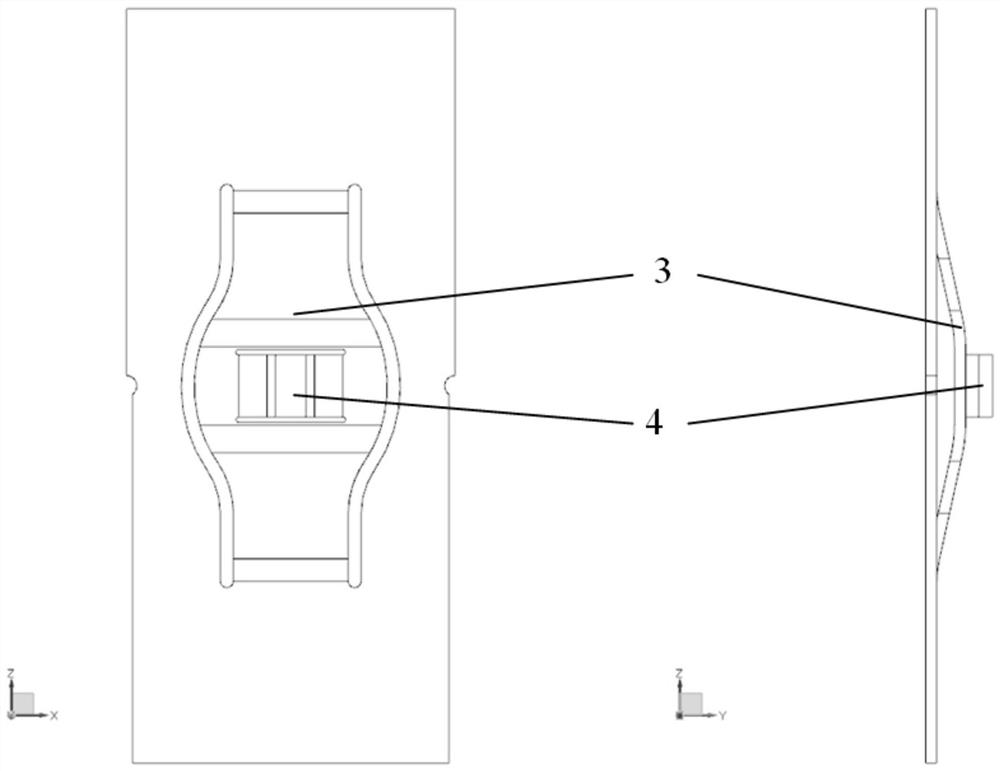

[0037] In order to solve the problem that the existing spring structure increases the overall resistance of the grid, this embodiment proposes the following image 3 The shown lattice spring structure uses the superposition of the elastic member 3 and the rigid member 4 to improve the anti-abrasion performa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com