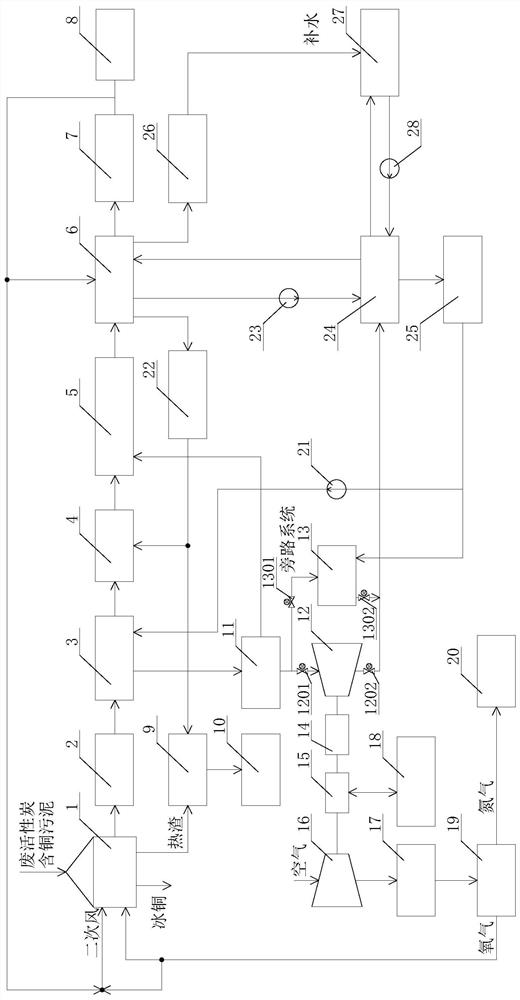

Energy-saving and water-saving coupled carbon complementation solid hazardous waste treatment system and method

A treatment system and replenishment technology, which is applied in the field of solid and hazardous waste treatment systems with energy saving and water saving coupled with carbon replenishment, can solve the problems of high comprehensive energy consumption of the system, high carbon dioxide gas, difficulty in meeting carbon emission indicators, etc., and achieve combustion intensity. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

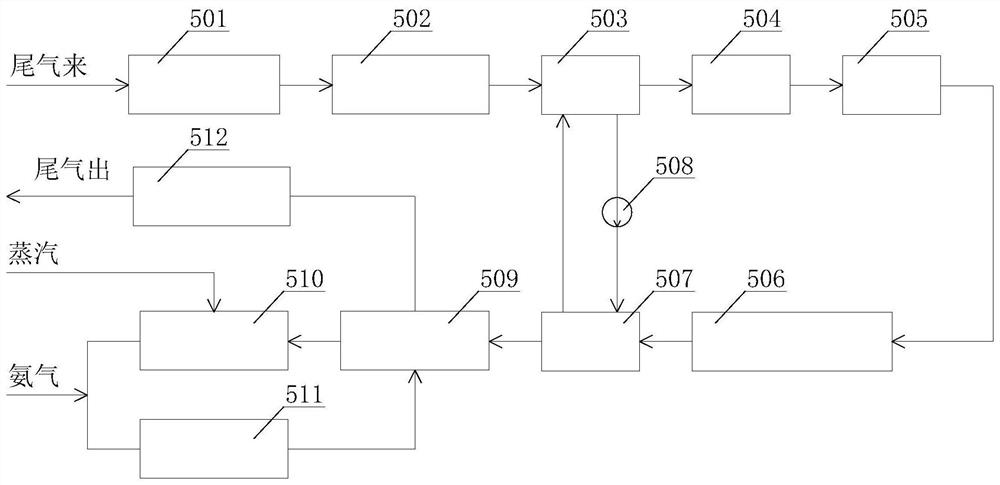

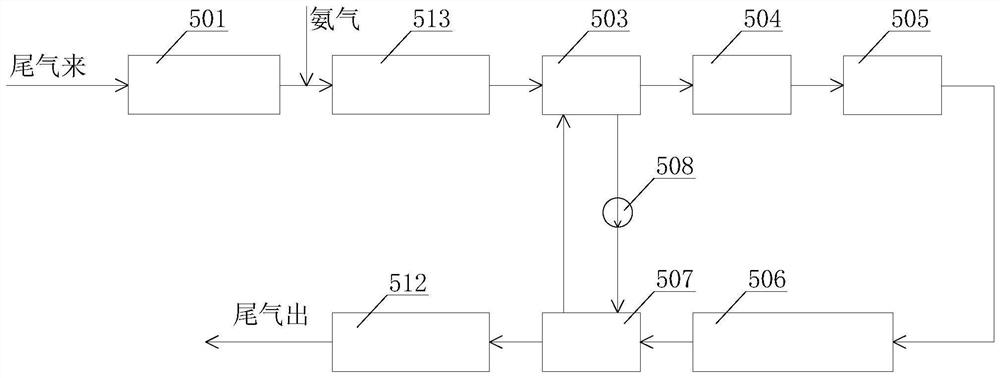

[0060] The following is an analysis of operating parameters in conjunction with a 2×100,000-ton annual copper-containing sludge disposal production line. The exhaust gas purification system adopts the second scheme. The specific operating parameters are as follows:

[0061] Oxygen-enriched side-blowing furnace processing scale: 100,000 t / a,

[0062] Oxygen-enriched side blowing furnace top exhaust gas temperature: 1050°C,

[0063] Oxygen consumption of oxygen-enriched side-blowing furnace: 28000Nm 3 / h

[0064] Oxygen-enriched side blowing furnace reflux carbon dioxide volume: 41000Nm 3 / h

[0065] (1) Main components of furnace top exhaust gas:

[0066] Exhaust gas flow: 72000Nm 3 / h

[0067] Tail gas water vapor volume fraction: 5.87%,

[0068] Tail gas carbon dioxide volume fraction: 90.3%,

[0069] Exhaust oxygen volume fraction: 3.83%,

[0070] Concentration of major pollutants in furnace top exhaust gas:

[0071] Exhaust gas NOx concentration: 250mg / Nm 3 ,

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com