Disc dryer convenient in tail gas treatment

A technology for disc dryers and dryers, applied in non-progressive dryers, dryers, drying solid materials, etc., which can solve problems such as large tail gas volume, excessive air particle size, and air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

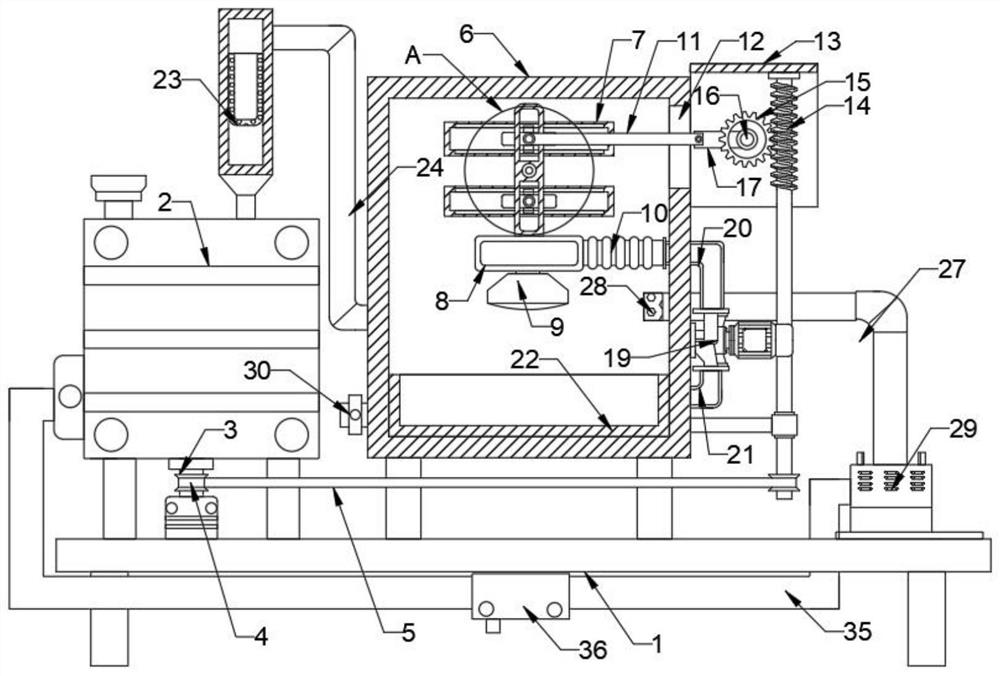

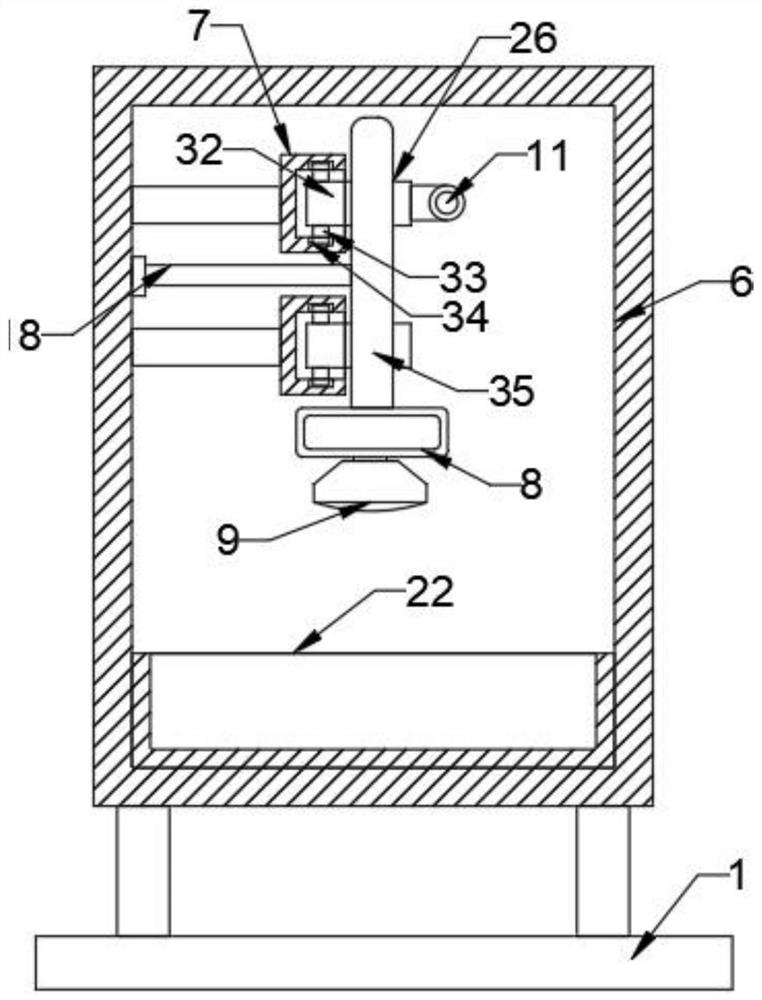

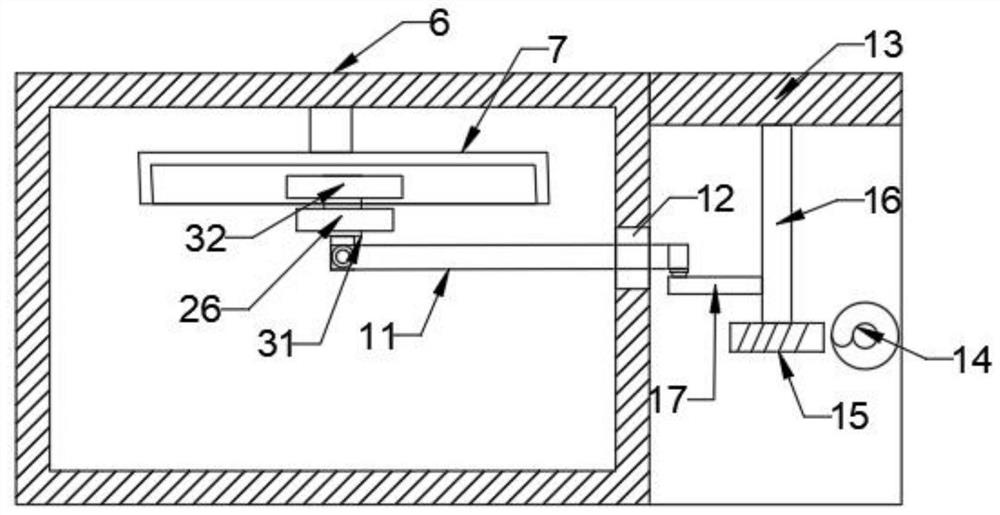

[0027] refer to Figure 1-4 , including a base 1, characterized in that the top side of the base 1 is fixedly connected with a dryer body 2, the dryer body 2 includes a main shaft 3, the top side of the base 1 is fixedly connected with a box body 6, and the upper part of the box body 6 is along the Two bearing frames 7 are fixedly connected in the vertical direction, and the inner sides of the two bearing frames 7 are slidingly connected with movable blocks 32, and the two movable blocks 32 are fixedly connected with projections 31, one of the two bearing frames 7 The side is provided with a moving rod 26 that is rotatably connected to the inner wall of the box body 6, and the upper and lower parts of the moving rod 26 are provided with movable grooves 25 for use with the protrusions 31, and one of the two protrusions 31 is rotated by a pin shaft. A movable rod 11 that runs through the side wall of the box body 6 is connected, a fixed frame 13 is fixedly connected to one side ...

Embodiment 2

[0030] refer to Figure 1-4 , the moving rod 26 is fixedly connected with a support rod 18 near the inner wall side of the box body 6, and one end of the support rod 18 is rotationally connected with the inner wall of the box body 6 through a rotating shaft, and the top and bottom of the two movable blocks 32 are fixedly connected There is a sliding block 33, and the sliding block 33 is slidably connected with the inner wall of the bearing frame 7 through the chute 34, and the sliding block 33 is used to slide in the chute 34, thereby further enhancing the stability of the movable block 32.

Embodiment 3

[0032] refer to Figure 1-4 , the air inlet of the blower fan 29 is connected with an air outlet pipe 27, and the air inlet of the air outlet pipe 27 is connected with the middle part of the box body 6, and the air outlet of the fan 29 is connected with a return pipe 35, and the return pipe 35 The extended end of the dryer body 2 communicates with each other, and a low-temperature water removal device 36 is installed on the return pipe 35. The high-humidity gas is processed in the low-temperature water removal device 36 to remove water vapor, and enters the dryer again through the return pipe 35 In the heater on the body 2, a closed cycle is achieved to avoid emissions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com