Soybean meal enzymolysis feed additive production system and production method

A feed additive and production system technology, which is applied in the methods of stress-stimulated microbial growth, biochemical equipment and methods, and feed, etc., can solve the problems of unstable product quality, low enzymatic hydrolysis efficiency, and high post-processing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

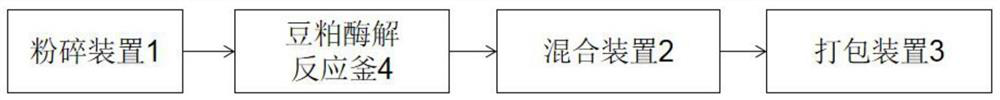

[0071] This embodiment provides a production method of soybean meal enzymatic hydrolysis feed additive, the specific steps are as follows:

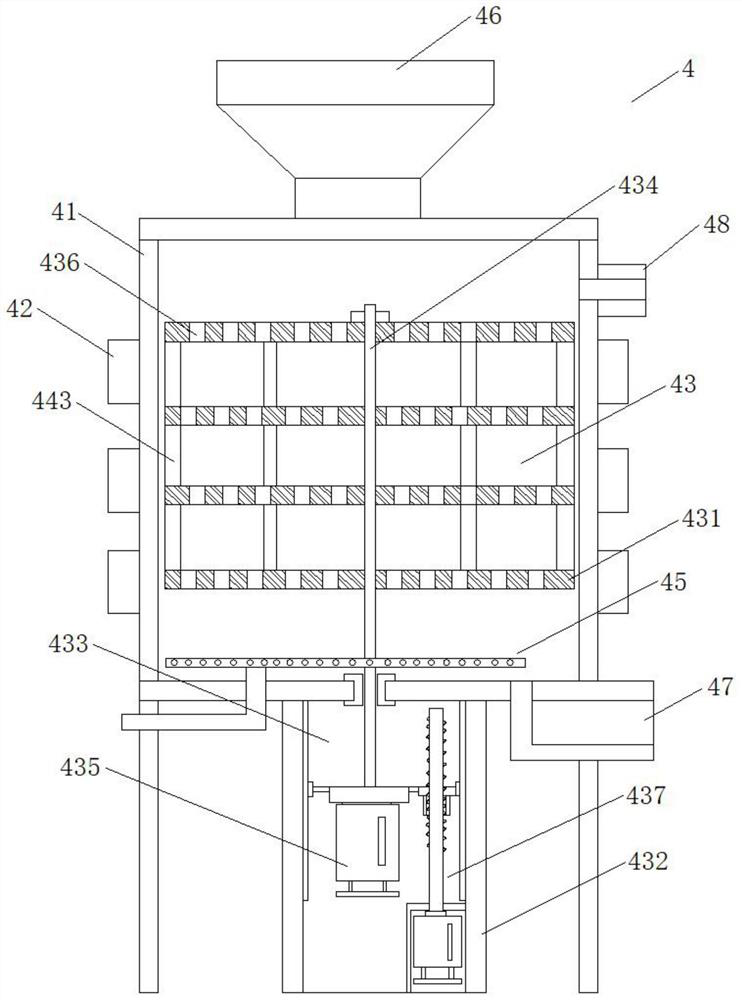

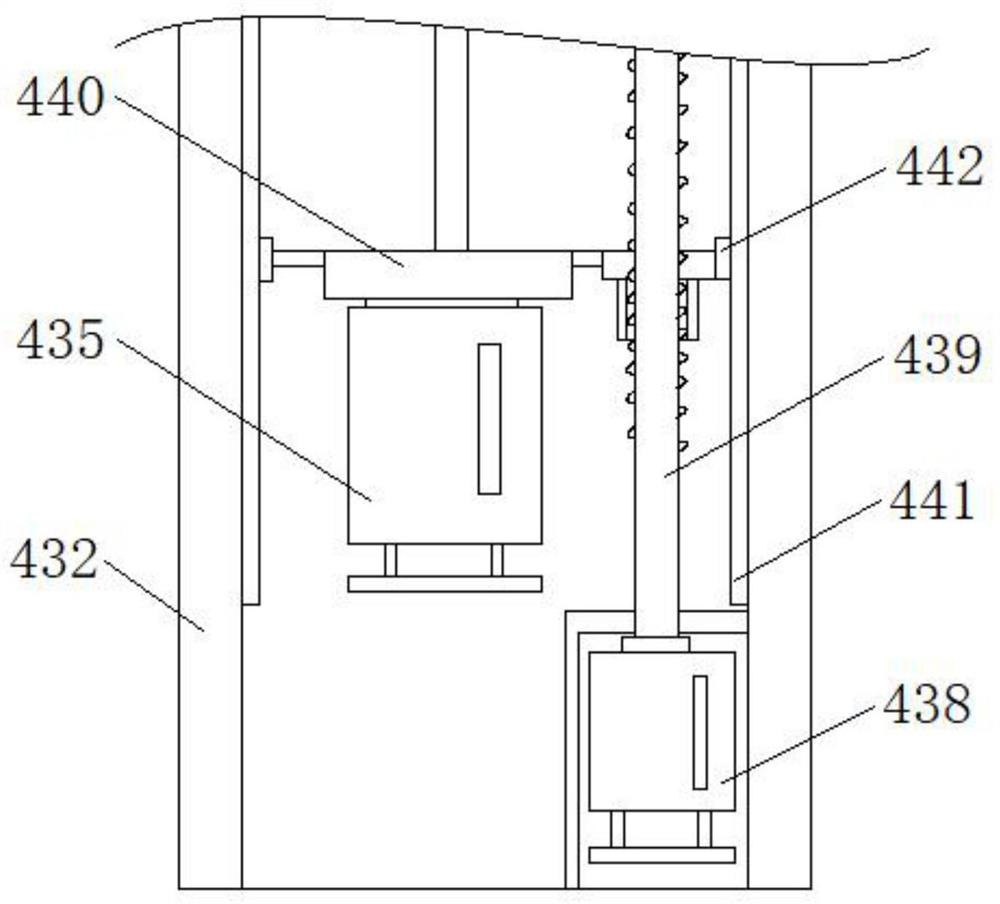

[0072] Step 1: Put the soybean meal into a crushing device and crush it to below 100 mesh, weigh 100 parts by weight of soybean meal powder and put it into a soybean meal enzymatic hydrolysis reaction kettle, add 2 parts by weight of acid protease for enzymolysis, and control the enzymatic hydrolysis temperature at 45 ℃, the time is 30 minutes, the vibration period of the ultrasonic generator in the soybean meal enzymatic hydrolysis reactor is controlled to 0.5 cycles / min, the power is 200-250W, and the frequency is 120kHz;

[0073] Step 2, after the enzymatic hydrolysis, add 10 parts by weight of magnesium oxide, adjust the pH to 3.0 with hydrochloric acid, and react at a constant temperature for 1.8 hours;

[0074] Step 3: adding ethanol to wash, and controlling the centrifugal rotation of the reactor to obtain the desired soybean meal ...

Embodiment 2

[0076] This embodiment provides a production method of soybean meal enzymatic hydrolysis feed additive, the specific steps are as follows:

[0077] Step 1: Put the soybean meal into a crushing device and crush it to below 100 mesh, weigh 100 parts by weight of soybean meal powder and put it into a soybean meal enzymatic hydrolysis reaction kettle, add 2 parts by weight of acid protease for enzymolysis, and control the enzymatic hydrolysis temperature at 45 ℃, the time is 30min, the vibration period of the ultrasonic generator in the soybean meal enzymatic hydrolysis reactor is controlled to 0.5 cycle / min, the power is 200-250W, and the frequency is 130kHz;

[0078] Step 2, after the enzymatic hydrolysis, add 10 parts by weight of magnesium oxide, adjust the pH to 3.0 with hydrochloric acid, and react at a constant temperature for 1.8 hours;

[0079] Step 3: adding ethanol to wash, and controlling the centrifugal rotation of the reactor to obtain the desired soybean meal enzyma...

Embodiment 3

[0081] This embodiment provides a production method of soybean meal enzymatic hydrolysis feed additive, the specific steps are as follows:

[0082] Step 1: Put the soybean meal into a crushing device and crush it to below 100 mesh, weigh 100 parts by weight of soybean meal powder and put it into a soybean meal enzymatic hydrolysis reaction kettle, add 2 parts by weight of acid protease for enzymolysis, and control the enzymatic hydrolysis temperature at 45 ℃, the time is 30min, the vibration period of the ultrasonic generator in the soybean meal enzymatic hydrolysis reactor is controlled to 0.5 cycles / min, the power is 200-250W, and the frequency is 140kHz;

[0083] Step 2, after the enzymatic hydrolysis, add 10 parts by weight of magnesium oxide, adjust the pH to 3.0 with hydrochloric acid, and react at a constant temperature for 1.8 hours;

[0084] Step 3: adding ethanol to wash, and controlling the centrifugal rotation of the reactor to obtain the desired soybean meal enzym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com