Thermally activated polyurethane hot melt adhesive and preparation method thereof

A technology of polyurethane hot melt adhesive and heat activation, which is applied in the direction of polyurea/polyurethane adhesive, adhesive, adhesive type, etc., and can solve the problem of short storage period of hot melt adhesive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

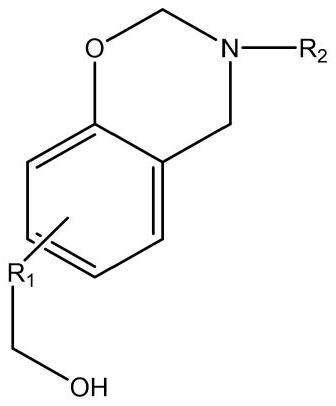

Image

Examples

preparation example Construction

[0027] The preparation of polyurethane involves:

[0028] Step 1. In the presence of a protective gas, put the polymer polyol, optional chain extender, catalyst, and auxiliary agent into the reaction vessel, heat up to 110-135° C. and vacuumize and dehydrate for 1-3 hours;

[0029] Step 2, cooling the mixture obtained in step 1 to 55-70°C, adding polyisocyanate, raising the temperature to 90-100°C and continuing the reaction for 1-2 hours to obtain polyurethane with an NCO mass content of 2-5%;

[0030] Among them, the test of NCO mass content is to use the -NCO group contained in the polyurethane obtained by the reaction to react with excess di-n-butylamine to produce urea, and then titrate the excess di-n-butylamine with hydrochloric acid to quantitatively calculate the mass content of NCO.

[0031] The protective gas is a gas with stable chemical properties and does not participate in the reaction process or reaction. Preferably, the protective gas is nitrogen;

[0032] Pr...

Embodiment 1

[0072] Preparation method of heat-activated polyurethane hot-melt adhesive: In the presence of nitrogen, control the temperature of polyurethane (a1) to 90°C to make it in a molten state, add an active hydrogen-containing oxazine small molecule compound and a catalyst, stir and react for 1 hour, pack saved;

[0073] Wherein, the molar ratio of the active hydrogen to the NCO of the polyurethane in the oxazine small molecular compound containing active hydrogen is 1:1.

Embodiment 2

[0075] Preparation method of heat-activated polyurethane hot-melt adhesive: In the presence of nitrogen, control the temperature of polyurethane (a2) to 110°C to make it in a molten state, then add an active hydrogen-containing oxazine small molecule compound and a catalyst to stir and react for 0.8h, The packaging is preserved;

[0076] Wherein, the molar ratio of the active hydrogen to the NCO of polyurethane in the oxazine small molecular compound containing active hydrogen is 1:0.8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com