Stage-skip AAO sewage treatment method adopting filter tank

A sewage treatment method and filter tank technology, which are applied in the field of water treatment, can solve the problems of lack of anaerobic zone and sludge return, inability to install fans, and large workload of on-site installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

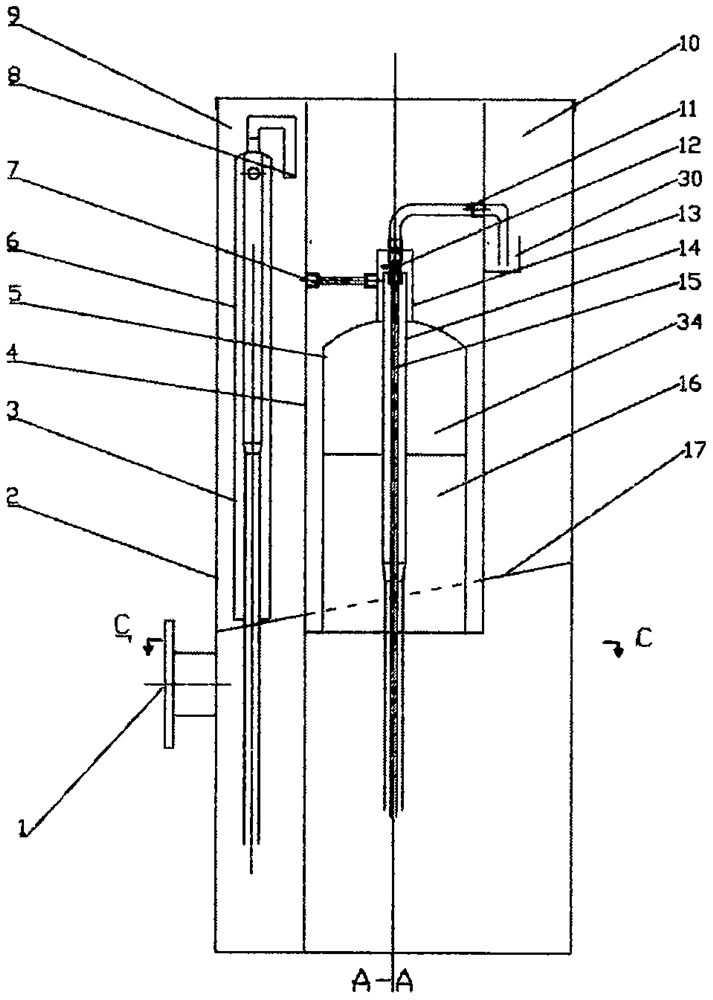

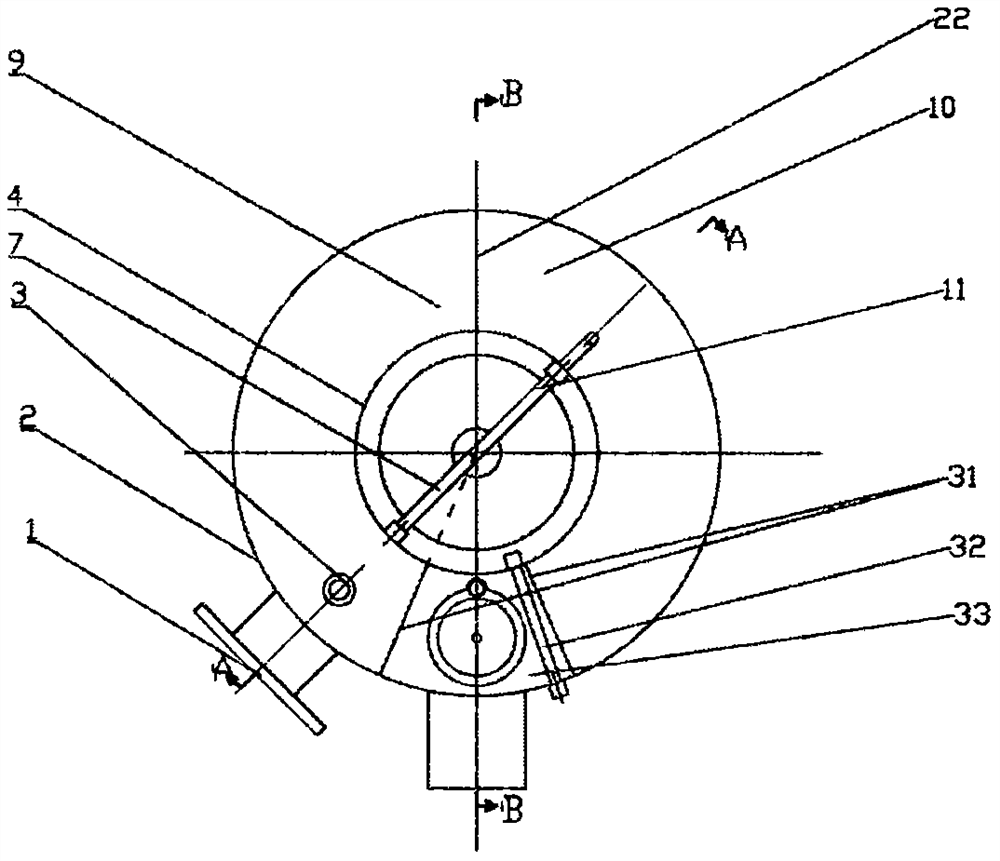

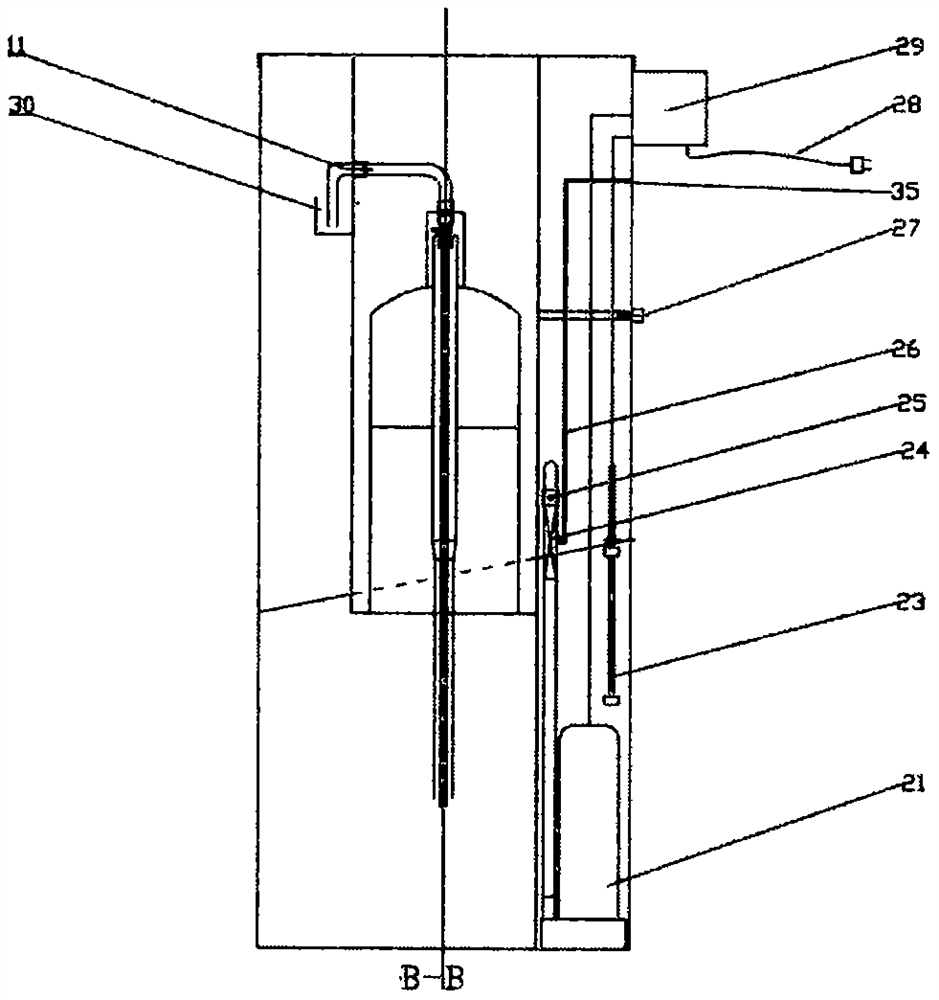

[0025] As shown in the attached picture, the integrated sewage processor has a treatment capacity of 5 tons per day and uses a 180W pump. In the figure, the inclined middle partition 17 separates the whole bucket body 2 into upper and lower layers, but there is a gap at the equipment compartment 33; the inclined middle partition 17 forms the lowest point near the top of the sewage water inlet 1 of the secondary sedimentation tank 9, In order to accumulate sludge; the anaerobic zone 18 and the anoxic zone 19 are located in the lower floor respectively, separated by a partition 20; the filter tank 5 and the backwash water reservoir 4 are located in the upper floor; the vertical partition 22 and two 31 buckets The annular pool between the body 2 and the reservoir 4 is divided into an aerobic zone 10, a secondary settling tank 9 and an equipment warehouse 33, wherein the aerobic zone 10 is basically above the anoxic zone 19, and the secondary settling tank 9 is in the anaerobic zon...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap