Two-dimensional material, preparation and assembly method and application of two-dimensional material in artificial nerve component

A technology of two-dimensional materials and assembly methods, applied in the field of two-dimensional materials, can solve problems such as unfavorable applications, small size, and large thickness of two-dimensional materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

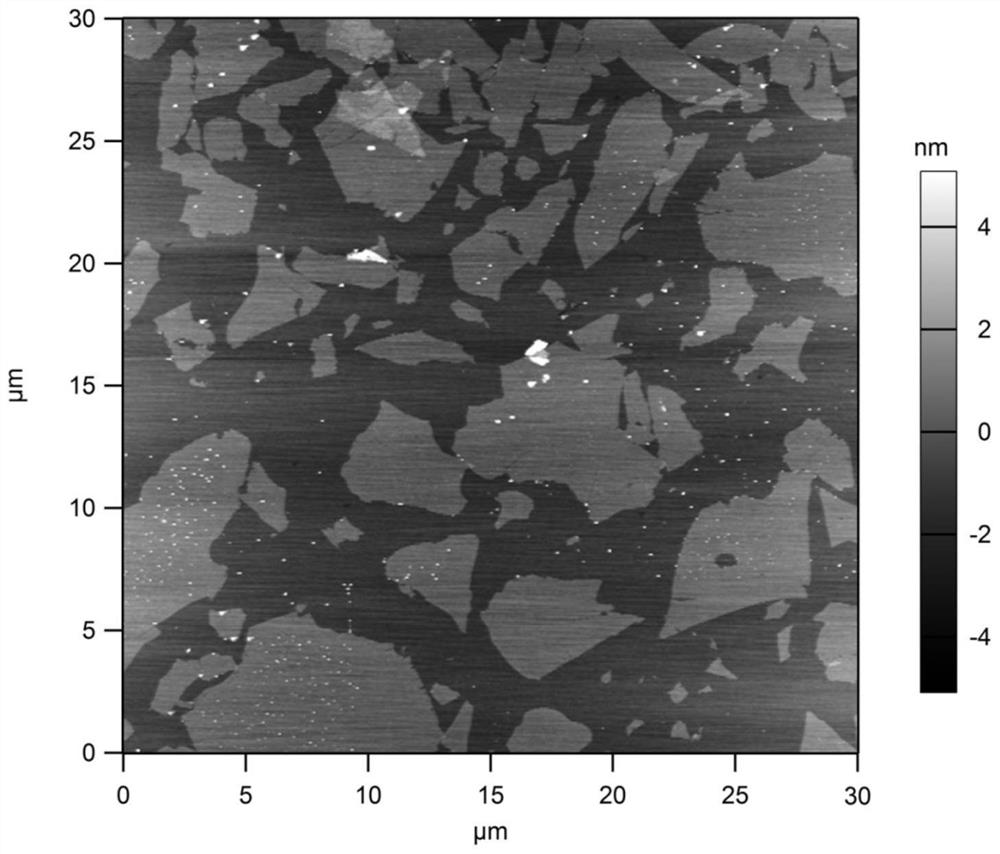

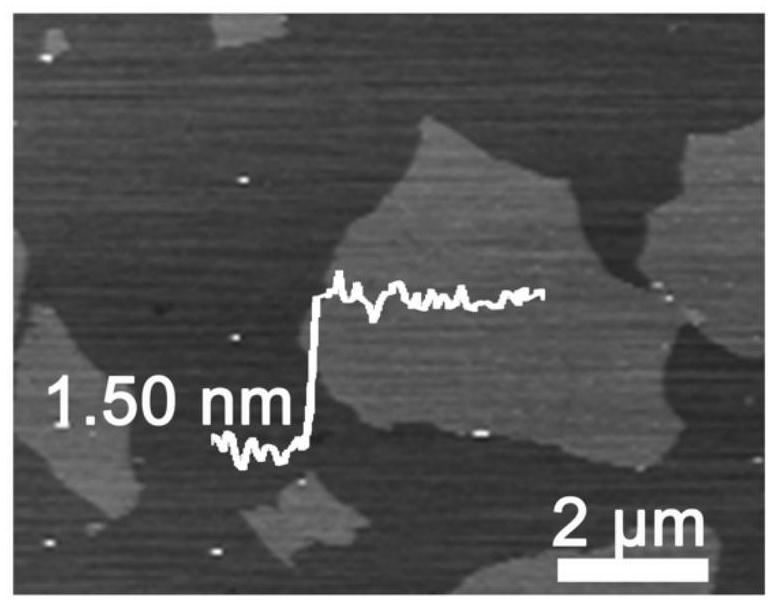

[0081] This embodiment provides a two-dimensional material. The two-dimensional material is high-quality two-dimensional titanium dioxide. The specific preparation process includes the following steps:

[0082] (1) Take 10.4 g of rutile phase titanium dioxide powder, mix with 2.4 g of potassium carbonate and 0.8 g of lithium carbonate, and calcined at 1000° C. for 5 hours to obtain a calcined product. After grinding at room temperature, calcined at 1000° C. for 20 hours to obtain the final calcined product.

[0083] (2) 1 g of the final calcined product was mixed with 200 mL of 1 mol / L hydrochloric acid solution and stirred for 4 days, so that hydrogen ions were fully intercalated into the titanium dioxide layer of the calcined product to obtain a primary intercalation product.

[0084] (3) Immerse the primary intercalation product in 10% w / v tetrabutylammonium hydroxide (TBAOH) solution for 5 hours, using TBA + The ions open up the interlayers to obtain secondary intercalatio...

Embodiment 2

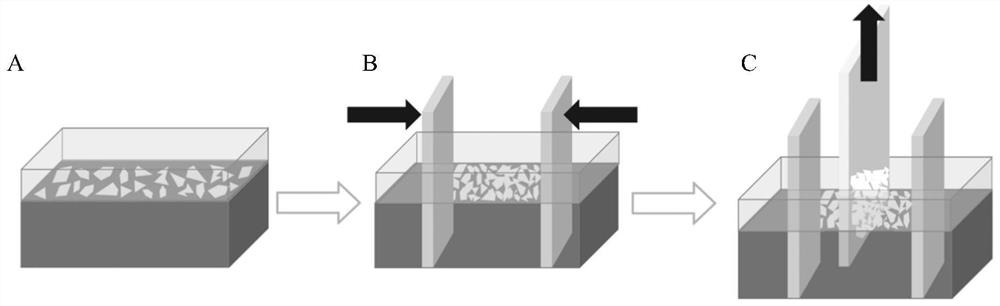

[0088] This embodiment provides a two-dimensional film, the two-dimensional film is ultra-thin large-area two-dimensional titanium dioxide, assembled from the two-dimensional material in Example 1, the assembly method is as follows image 3 As shown, it specifically includes the following steps:

[0089] (1) Take 3 mL of the initial two-dimensional titanium dioxide solution after shaking for 2 days in Example 1, and evaporate it to 99% dryness at 80° C. under normal pressure. Then directly add 8 mL of volatile organic solvent (the volume ratio of ethanol and chloroform is 1:1), ultrasonically disperse for 24 hours, and prepare a dispersion liquid of 0.3 mg / mL titanium dioxide two-dimensional nanosheets.

[0090] (2) Wash the pre-prepared sink with ethanol and ultrapure water for 3 times continuously, and mark the effective compression area as 105cm 2 , to fix the starting positions of the sliders at both ends.

[0091] (3) Slowly fill the ultrapure water into the water tank ...

Embodiment 3

[0100] This embodiment provides a two-dimensional film. The two-dimensional film is a large-area and highly transparent titanium dioxide ultra-thin film. thin glass.

[0101] The photos of the large-area and highly transparent titanium dioxide ultra-thin film prepared by this example are as follows: Figure 9 As shown, it can be seen from the figure that the prepared titanium dioxide nanosheet assembled film is extremely transparent, and the background of the part covered by the assembled film on the right is still clearly visible.

[0102] Take the assembled films with different numbers of layers prepared by different pulling times, and measure their transmittance for 550nm light. The results are as follows: Figure 10 As shown, it can be seen from the figure that the transmittances of the high-transmittance films with different layers provided in this embodiment are all greater than 98% under 550nm light.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com