Biodiesel distillation vacuum tail gas treatment device

A tail gas treatment and tail gas technology, applied in the fields of biofuel, vapor condensation, distillation adjustment/control, etc., can solve the problems of methanol waste, affecting the production environment and safety, and achieve the effect of ensuring safe operation and no environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The biodiesel distillation vacuum tail gas treatment device of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

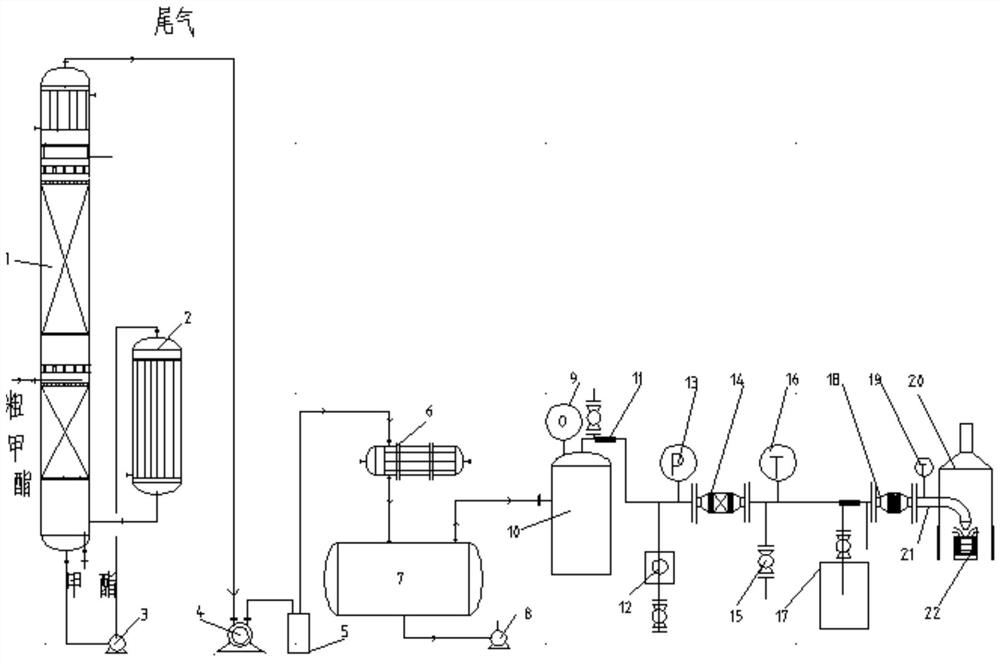

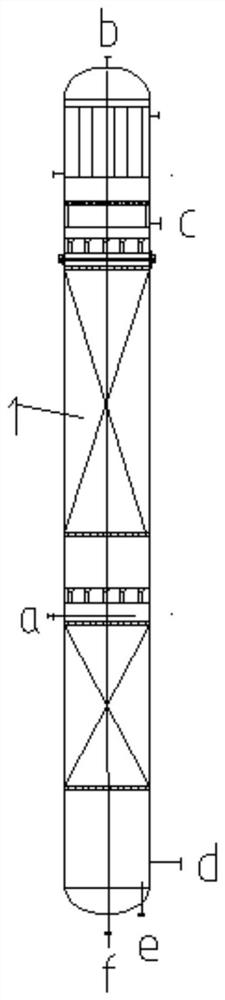

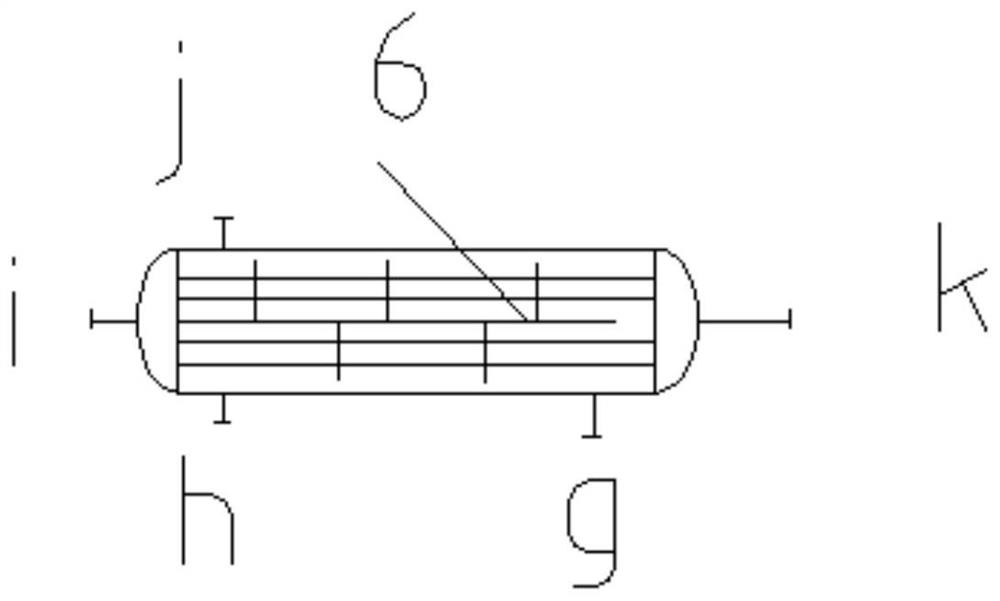

[0021] Figure 1-Figure 5As shown, the biodiesel distillation vacuum tail gas treatment device of the present invention includes a tail gas vacuum unit 4, a working fluid tank 5 of the tail gas vacuum unit, a horizontal condenser 6, a methanol receiving tank 7, an outlet pump 8 of the methanol separation receiving tank, and an oxygen content control system 9 , methanol separator 10, mixing heat pipe 11, pipe separator 12, pressure control system 13, gravel flame arrester 14, fire extinguishing steam pipe 15, front temperature control system 16, safety water seal 17, stainless steel flame arrester 18, rear temperature control system 19. Combustion furnace 20, vacuum tail gas pipe 21, coal furnace 22; the inlet of the tail gas vacuum unit 4 is connected to the vacuum outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com