Method for forming three-dimensional structure of multi-layer conductive sheet

A technology of three-dimensional structure and forming method, applied in multilayer circuit manufacturing, 3D structure electroforming, electroforming, etc., can solve the problems of reduced feature size, high equipment requirements, and no technical solutions, etc., to achieve line hole formation The process is mild, the depth of drilling is controlled, and the effect of lowering the threshold of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

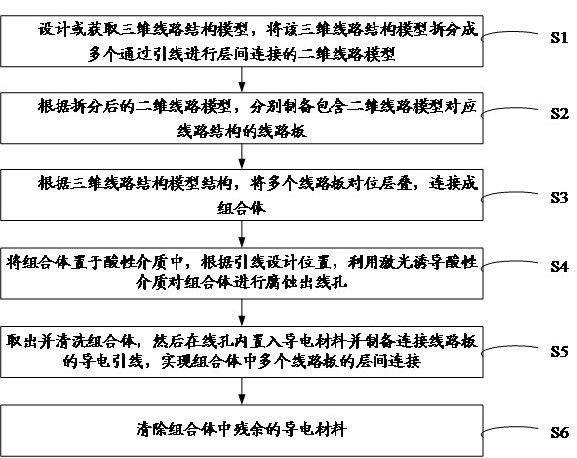

Method used

Image

Examples

Embodiment 1

[0062] According to the use requirements, design a three-dimensional circuit structure model with a three-layer circuit structure, decompose the three-dimensional circuit structure model into three two-dimensional circuit models connected by vertical leads, and prepare three corresponding copper-containing circuit models by laser sintering. The circuit boards of high-quality circuits, the three circuit boards are connected in sequence and facing positions through glass spacers and adhesive glue to form an assembly, and the assembly is placed in the designated position of sulfuric acid solution with pH=5.2, according to the three-dimensional The position of the lead in the circuit structure model is irradiated with an ultraviolet laser with a wavelength of 357nm to heat the circuit on the circuit board, so that the temperature of the irradiation position is raised to above 50°C, and the sulfuric acid solution corrodes the circuit at the heated position to form a line hole of the ...

Embodiment 2

[0064] According to the use requirements, design a three-dimensional line structure model with a three-layer line structure, decompose the three-dimensional line structure model into three two-dimensional line models connected by vertical leads, and prepare glass blocks with openings corresponding to the positions of the leads , using laser sintering to prepare three corresponding circuit boards containing copper circuits on the glass block, and connecting the three circuit boards in sequence and facing the glass to form an assembly through adhesive glue. The assembly is placed in a designated position in a formic acid atmosphere containing water vapor, and the defect position is irradiated with an ultraviolet laser 5 with a wavelength of 357nm to heat the circuit on the circuit board, and the temperature of the irradiation position is raised to above 80°C, and the formic acid atmosphere containing water vapor Erosion the line at the heating position to form a line hole with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com