Intelligent constant-temperature variable-frequency drying system based on terahertz heat radiation

A drying system and terahertz technology, applied in the field of terahertz heating, can solve the problems of unsatisfactory drying effect, old electric heating drying technology, uneven heating area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The terahertz heating plate of the present invention is formed by sintering the modified tin dioxide electrothermal radiation film and glass ceramics; the terahertz circuit board is embedded in a high-temperature-resistant black glass-ceramic plate as a heat radiation source, and the target object is heated and dried ;

[0047] As an example provided by the present invention, preferably, the modified tin dioxide electrothermal radiation film is doped with nitrogen element, and the percentage content of nitrogen element in the tin dioxide film doped with nitrogen element is 0.4- 0.6, through the optimization of the formula of tin dioxide electrothermal radiation film, the terahertz radiation intensity produced by sintering with glass ceramics is high, combined with the intelligent control system provided by the present invention, the terahertz action distance can reach more than 2 meters, and the conversion efficiency is improved To more than 97%, the industrial applicat...

Embodiment 2

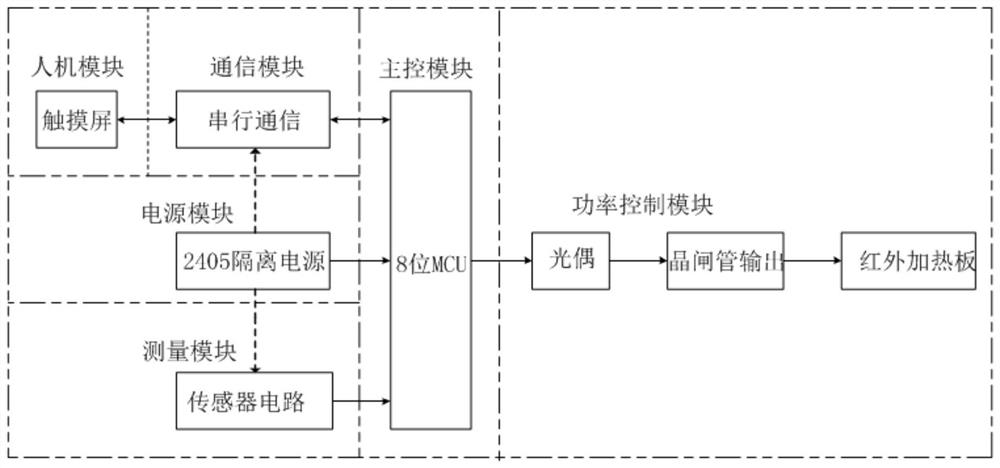

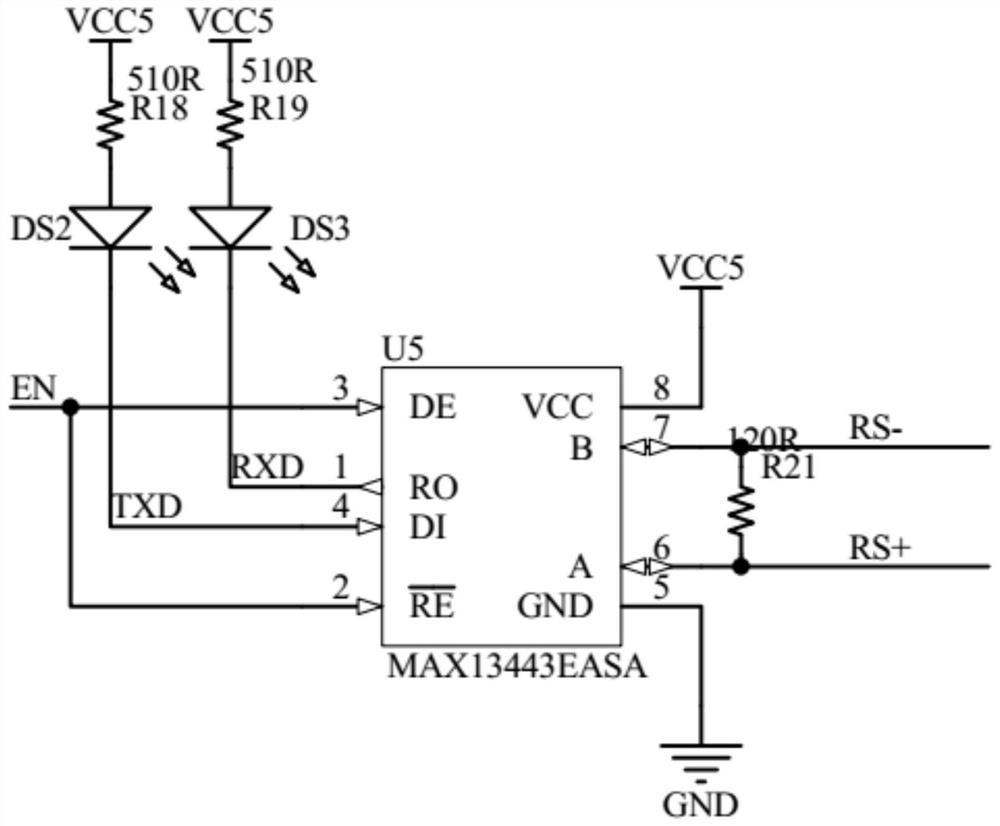

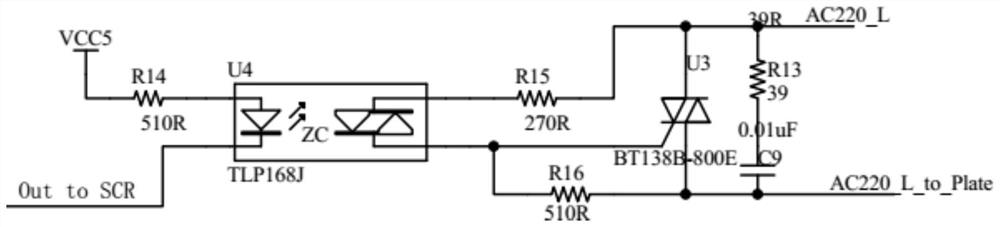

[0052] Depend on figure 1 It can be seen that the system takes an 8-bit microprocessor as the core, and the touch screen of the man-machine module exchanges data with the PC through the 485 chip. The target heating temperature can be input through the touch screen and exchange data with the PC through RS-485 communication. The current heating temperature is determined by the The temperature-to-digital converter with built-in bandgap temperature sensor and Σ-Δ analog-to-digital conversion function can provide overheat output and also serve as a temperature detector LM75A temperature sensor detection, directly convert the detected temperature signal into a digital signal, and transmit it to the microcontroller , and processed by the microcontroller; the microcontroller compares the current heating temperature with the set temperature, gives the control amount through a certain intelligent control algorithm, controls the optocoupler, and then controls the conduction angle of the t...

Embodiment 3

[0055] As an embodiment provided by the present invention, preferably, the main control module compares the current heating temperature with the set temperature, and obtains the control amount through an intelligent control algorithm, and the main control module includes a PIC16F1829-E / ML single-chip microcomputer, an external clock circuit , Reset circuit; MCU reset includes power-on reset (POR), brown-out reset (BOR), Reset, WDT reset, RESET instruction, stack overflow, stack underflow, programming mode exit 8 reset modes, the present invention adopts is reset mode. is an optional external input that resets the device, The function is controlled by the MCLRE bit of configuration word 1 and the LVP bit of configuration word 2. The specific control mode is shown in Table 1 configuration shown. when enabled And when the pin remains low, the device will remain in the reset state, the MCLR pin is connected to VDD through an internal weak pull-up, and the reset will not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com