Compressor surge prediction control method based on magnetic suspension axial position control

A technology of axial position and predictive control, applied in pump control, mechanical equipment, machine/engine, etc., can solve problems such as working range limitation, reduce system energy loss, etc., to eliminate surge, avoid surge, and reduce surge The effect of margin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

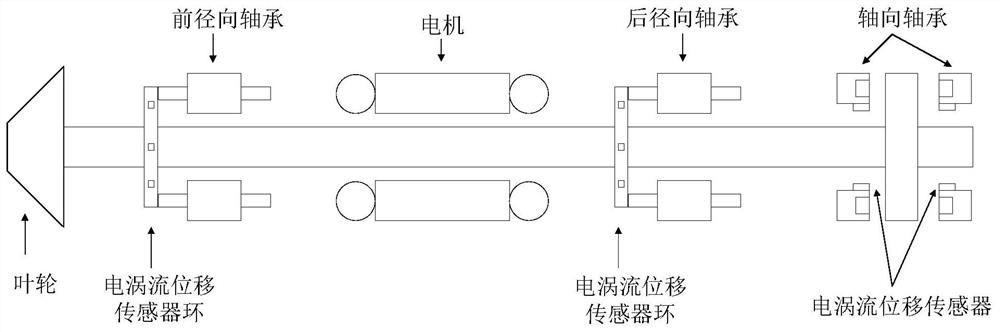

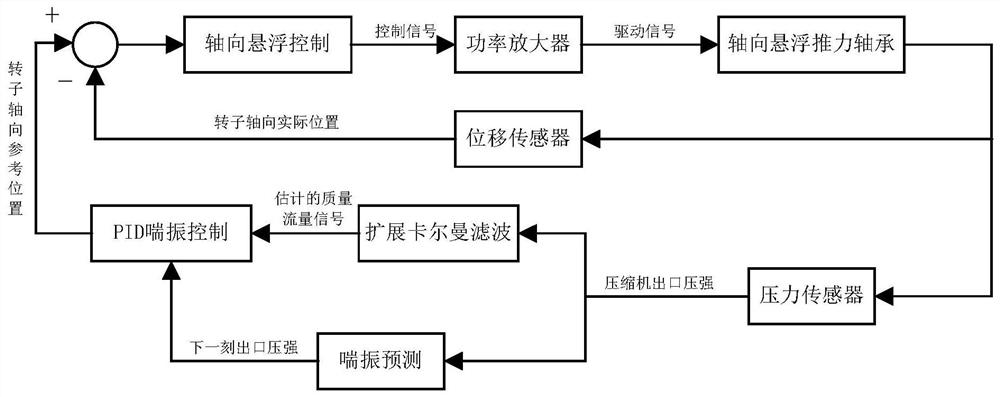

[0064] The invention will be further described below in conjunction with the accompanying drawings and specific implementation examples. The method of the present invention is an integrated compressor surge prediction control method based on axial magnetic levitation position control. Before the compressor system is officially started, the system characteristics are tested to determine the prediction point and draw the surge curve, and the compressor outlet is collected. Pressure information, using the support vector machine based on the least square method to judge whether there is surge, and when the surge is about to occur, adjust the control strategy in advance to increase the control current of the radial magnetic bearing, thereby suppressing the rotational disturbance force of the impeller due to stall, At the same time, by adjusting the axial position of the rotor to produce a small "offset" fluctuation on the output pressure of the compressor to suppress system surge, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com