Regenerated polyester staple fiber material and preparation method thereof

A technology for recycled polyester and staple fibers, which is applied in the fields of staple fiber formation, fiber treatment, and fiber chemical characteristics. It can solve problems such as unfavorable industrial production and broken filaments of recycled polyester staple fibers, achieve good wettability and softness, and improve antistatic properties. Sexy, smooth feel effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

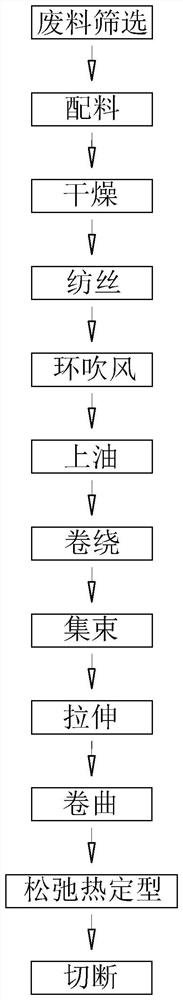

Image

Examples

preparation example 1

[0054] Weigh 141.5g of deionized water and add it to a four-necked flask with stirring, add 1.2g of Pingpinga O, 4.0g of geramine, 1.0g of WA water dispersant and 50g of octamethylcyclotetrasiloxane, and heat it in a water bath Raise the temperature to 40°C and stir for 1 h, add 0.2 g of catalyst KOH, adjust the rotation speed to 300 R, and control the temperature at 70°C for 4 h. Add 0.4g KH602, continue the reaction for 3h to end the reaction; cool to 50°C and add acetic acid to neutralize, adjust the pH to about 7; cool to room temperature and discharge. The lotion is milky with a bluish tinge.

preparation example 2

[0056] Weigh 141.5g of deionized water and add it to a four-neck flask with stirring, add 1.2g of Pingpinga O, 4.0g of germine, 1.0g of WA water dispersant and 60g of octamethylcyclotetrasiloxane, and heat it in a water bath Raise the temperature to 40°C and stir for 1 h, add 0.2 g of catalyst KOH, adjust the rotation speed to 300 R, and control the temperature at 70°C for 4 h. Add 0.5g KH602, continue the reaction for 3h to end the reaction; cool to 50°C and add acetic acid to neutralize, adjust the pH to about 7; cool to room temperature and discharge. The lotion is milky with a bluish tinge.

preparation example 3

[0058] Weigh 141.5g of deionized water and add it to a four-neck flask with stirring, add 1.2g of Pingpinga O, 4.0g of germine, 1.0g of WA water dispersant and 70g of octamethylcyclotetrasiloxane, and heat it in a water bath Raise the temperature to 40°C and stir for 1 h, add 0.2 g of catalyst KOH, adjust the rotation speed to 300 R, and control the temperature at 70°C for 4 h. Add 0.6g KH602, continue the reaction for 3h to end the reaction; cool to 50°C and add acetic acid to neutralize, adjust the pH to about 7; cool to room temperature and discharge. The lotion is milky with a bluish tinge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com