Efficiency improving method for biochar addition-based anaerobic membrane bioreactor

An anaerobic membrane bioreactor technology, which is applied in the field of efficiency enhancement of anaerobic membrane bioreactors, can solve the problems of low treatment efficiency, poor system stability, and reduce membrane fouling rate, etc., so as to promote anaerobic digestion and improve stability. The effect of sex, effective use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

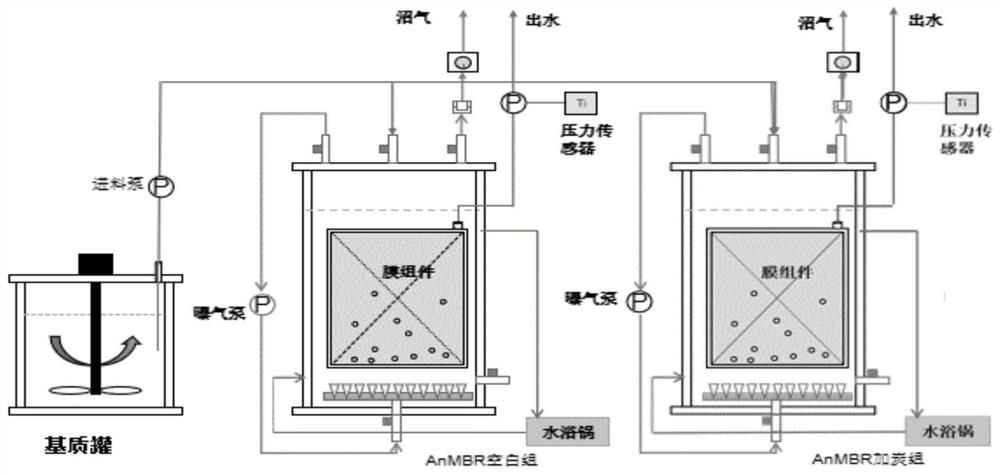

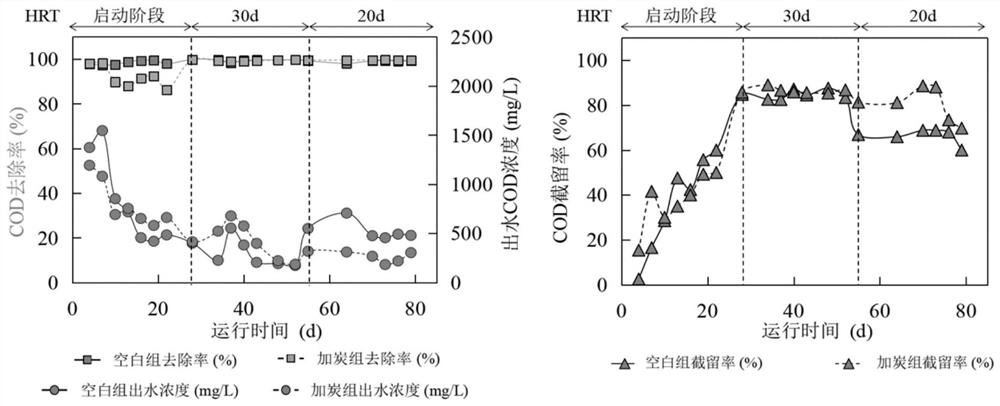

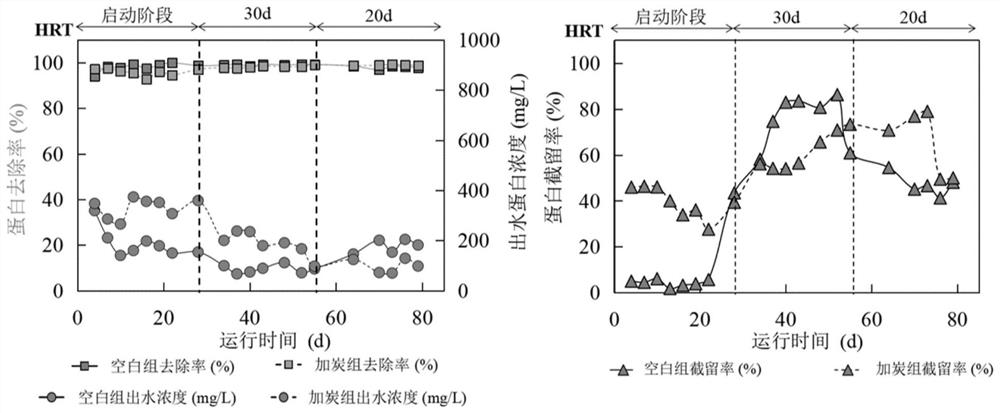

[0025] The specific implementation method of the present invention is as follows: artificially synthesized kitchen waste is used as a substrate and added to an anaerobic membrane bioreactor. When the gas group and gas volume of the anaerobic membrane bioreactor reach the theoretical value, the reactor is considered to be started successfully. Then add biochar to one of the reactors. During the operation, the gas production and gas components of the reactor are regularly measured, and the COD, polysaccharide, and protein contents of water and sludge are measured by sampling two to three times a week. The change of transmembrane pressure difference is recorded in real time to monitor membrane fouling. The specific steps are as follows.

[0026] (1) Preparation of walnut shell biochar: Take a certain amount of walnut shells and place them in the atmosphere furnace, blow nitrogen into the furnace for 5 minutes to eliminate the oxygen in the furnace, and then start the program to ke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com