Rapid cooling equipment for aluminum alloy handrail welding based on water-cooling heat dissipation

A water-cooled heat dissipation and rapid cooling technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of rapid temperature rise and affect the cooling efficiency of railings, so as to reduce noise, improve quietness, and improve cooling efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

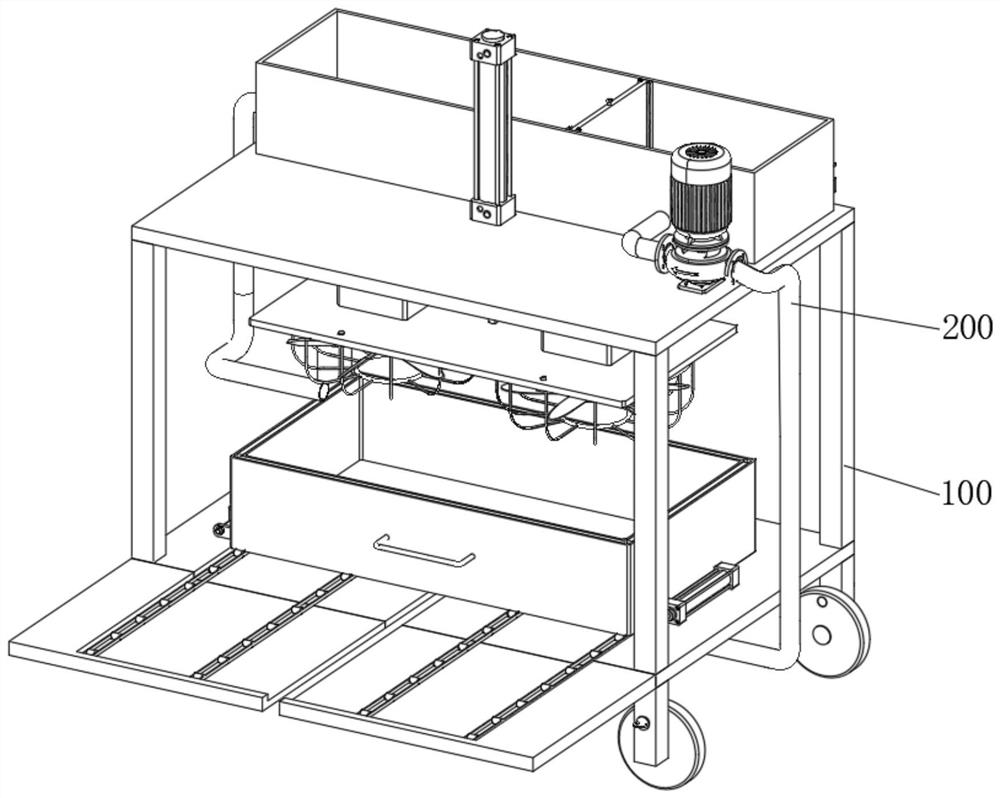

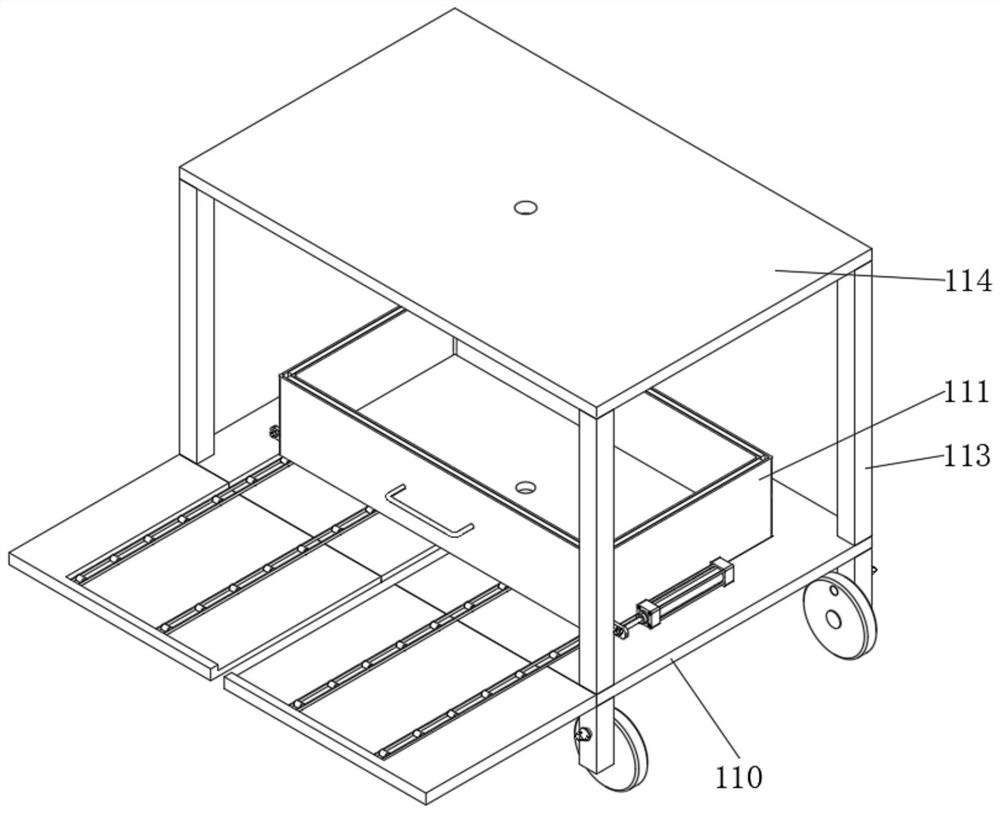

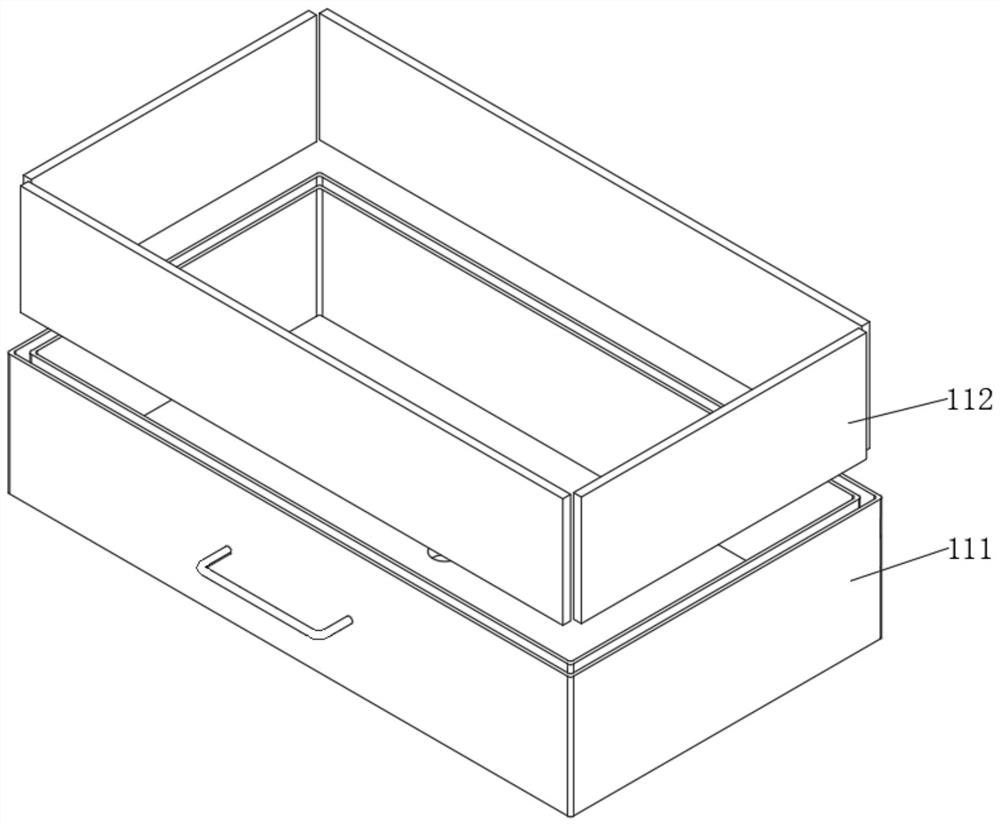

[0052] see Figure 1-Figure 9As shown, a rapid cooling equipment for aluminum alloy railing welding based on water cooling and heat dissipation is provided, including an installation device 100 and a refrigeration device 200 installed on the installation device 100, the installation device 100 includes a bottom plate 110, and a water storage tank 111 is provided on the top of the bottom plate 110 , the inner wall and the outer wall of the water storage tank 111 are provided with an installation cavity, the first cooling plate 112 is installed in the installation cavity, the four corners of the top of the bottom plate 110 are fixedly connected with a support rod 113, and one end of the support rod 113 is fixedly connected with a support plate 114, Refrigeration device 200 at least includes:

[0053] Stirring mechanism 210, stirring mechanism 210 comprises the second telescopic rod 211 that is installed on the top of support plate 114, the movable end of second telescopic rod 21...

Embodiment 2

[0062] In order to realize when removing impurity, prevent the outflow of water, carry out following improvement on the basis of embodiment 1:

[0063] see Figure 10 As shown, wherein, the bearing box 224 is fixedly connected with a clamping plate 270 on one side of the slot 240, the clamping plate 270 is in an “L” shape structure, and a chute structure is formed between the clamping plate 270 and the side wall of the bearing box 224, and the sliding A baffle plate 271 is slidably connected in the groove, and the top of the baffle plate 271 is fixedly connected with a back-moving spring 272, and the top of the back-moving spring 272 is fixedly connected with a mounting plate 273, and one side of the mounting plate 273 is fixed on the outer wall of the carrying case 224. When inserting plate 241, baffle plate 271 pushes baffle plate 271 to slot 240 by the elastic force of return spring 272, makes baffle plate 271 block slot 240, and then prevents the outflow of water, meanwhil...

Embodiment 3

[0065] In order to facilitate putting the railing into the water storage tank 111, the following improvements are made on the basis of Embodiment 1:

[0066] see Figure 11-Figure 12 As shown, wherein, one side of the base plate 110 is fixedly connected with an extension plate 120, the surface of the extension plate 120 and the base plate 110 is provided with a groove, the groove is slidably connected with the water storage tank 111, and the two ends of the surface of the base plate 110 are fixedly connected with a first Telescopic rod 121, the movable end of the first telescopic rod 121 is fixedly connected with the side wall of the water storage tank 111. When in use, the power supply of the first telescopic rod 121 is connected, and the movable end of the first telescopic rod 121 stretches out to drive the water storage tank 111 to move to the surface of the extension board 120 , thereby increasing the operating space for the staff, and making it easy to put the railing int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com