Organic waste resource pretreatment system and method

An organic waste and recycling technology, applied in the field of organic waste treatment, can solve the problems of unpleasant air, environmental pollution, long treatment time, etc., and achieve the effects of harmless pretreatment, low investment cost and high treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

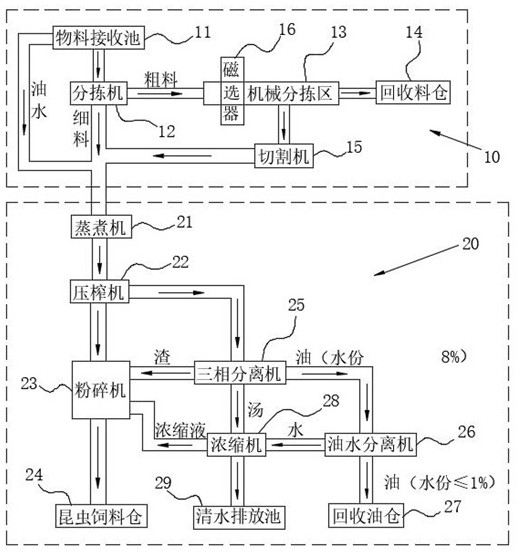

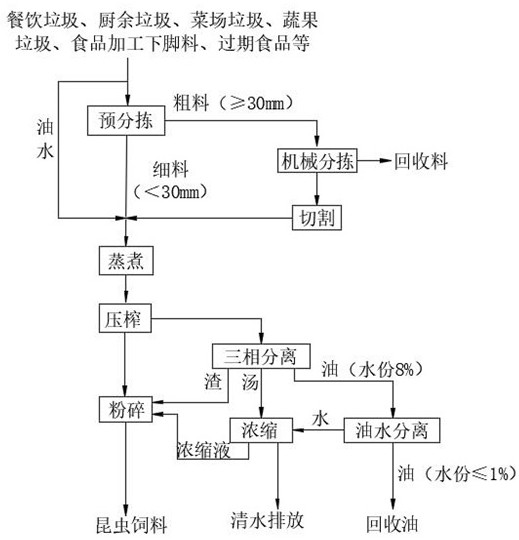

[0029] See figure 1 , figure 1 It is a structural schematic diagram of an organic waste resource recovery pretreatment system of the present invention. A pretreatment system for resource utilization of organic waste of the present invention includes a sorting module 10 and a processing module 20, the sorting module 10 includes a material receiving pool 11, a sorting machine 12, a mechanical sorting area 13, and a recycling bin 14 And cutting machine 15, processing module 20 comprises cooking machine 21, press machine 22, pulverizer 23, insect feed storehouse 24, three-phase separator 25, oil-water separator 26, recovery oil storehouse 27, concentrator 28 and clear water discharge pool 29 . In application, the material receiving pool 11 is used to receive organic wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com