Textile dye preparation system and method

A technology for preparing systems and dyes, applied in chemical instruments and methods, dissolution, metal processing, etc., can solve problems such as inability to flip, and achieve the effects of improving quality, reducing noise, and thoroughly utilizing value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

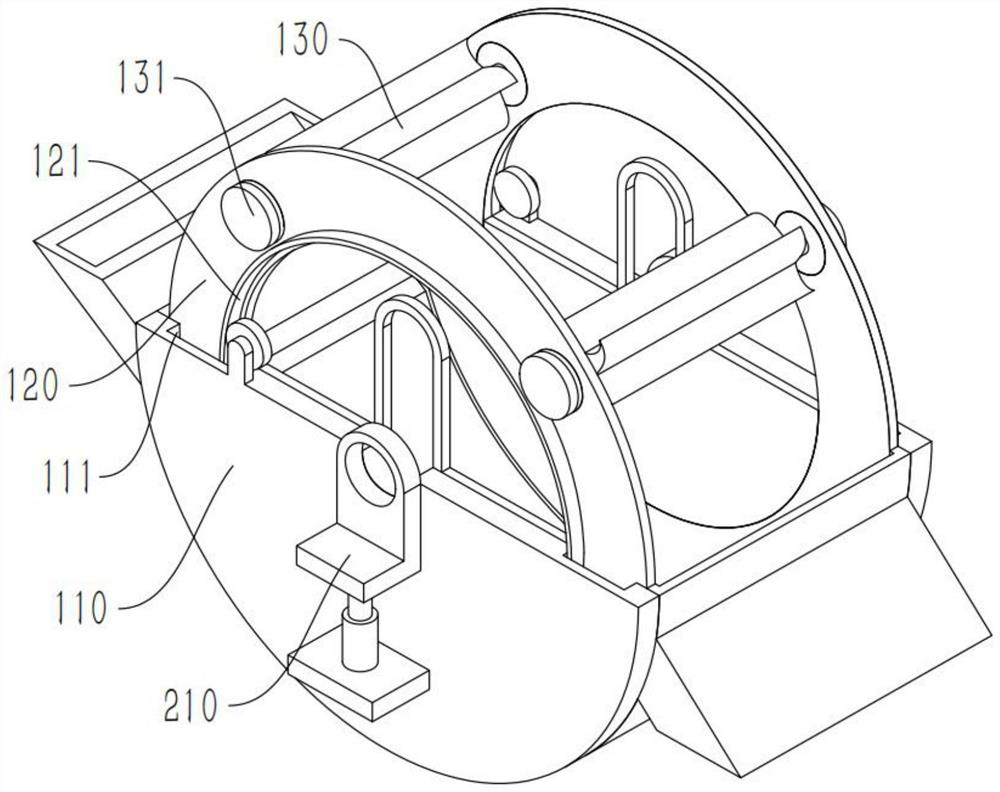

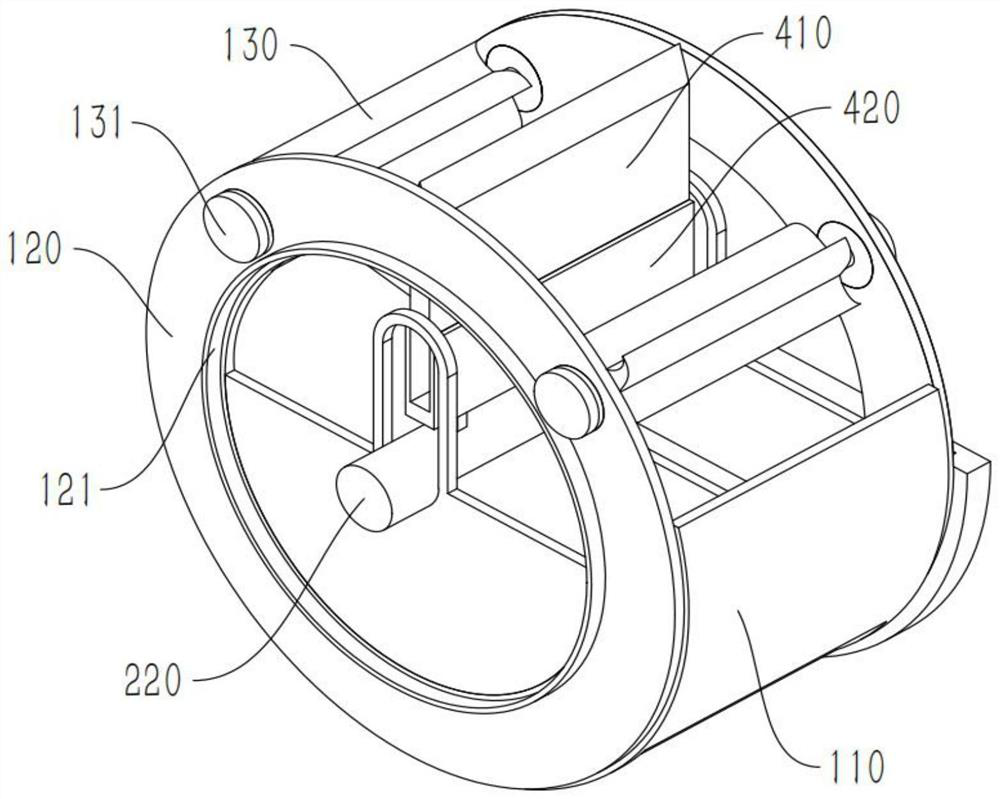

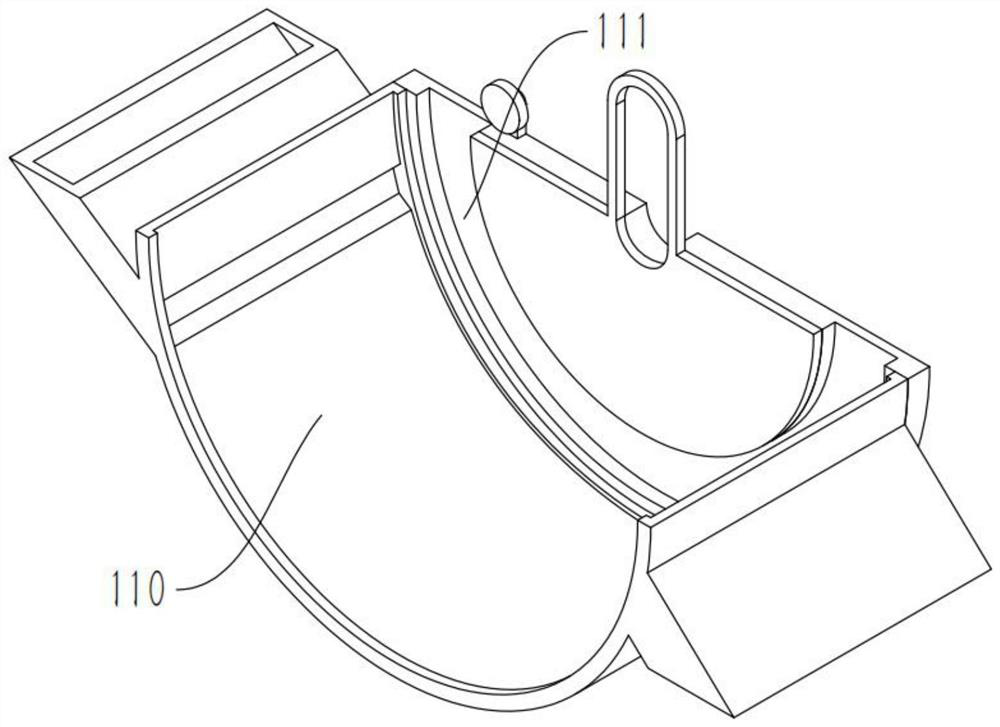

[0037] Such as figure 1 , 2 and 3,

[0038] Described a kind of textile dyestuff preparation system comprises processing case 110, rotating ring 120 and rotating leaf 130, and processing case 110 is provided with a material inlet, and processing case 110 is provided with a discharge port, and two rotating rings 120 are Rotationally connected in the processing box 110, the processing box 110 is provided with two rails 111, the two rotating rings 120 are fixedly connected with gear rings 121, and the front and rear ends of the two rotating rings 130 are fixedly connected with two friction wheels 131, a plurality of friction wheels 131 and two rails 111 friction transmission respectively, the rotating ring 120 is driven by external power, and the external power is a deceleration motor, the deceleration motor is fixedly connected to the processing box 110, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com