On-chip magnetic core power inductor with inductance value changing along with working current

A technology of working current and power inductance, applied in the application of transformer/inductor core, transformer/inductor shell, magnetic film to substrate, etc., can solve the problem of not being able to maintain low ripple current transient response capability, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

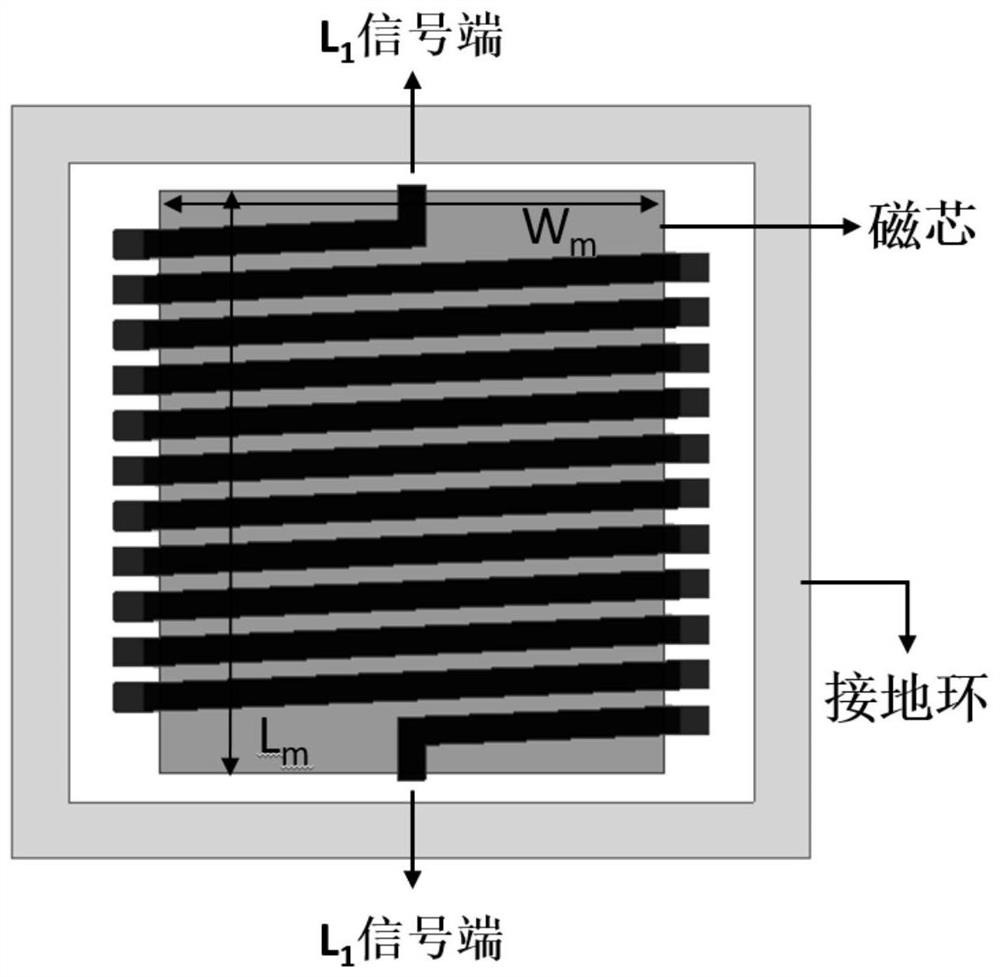

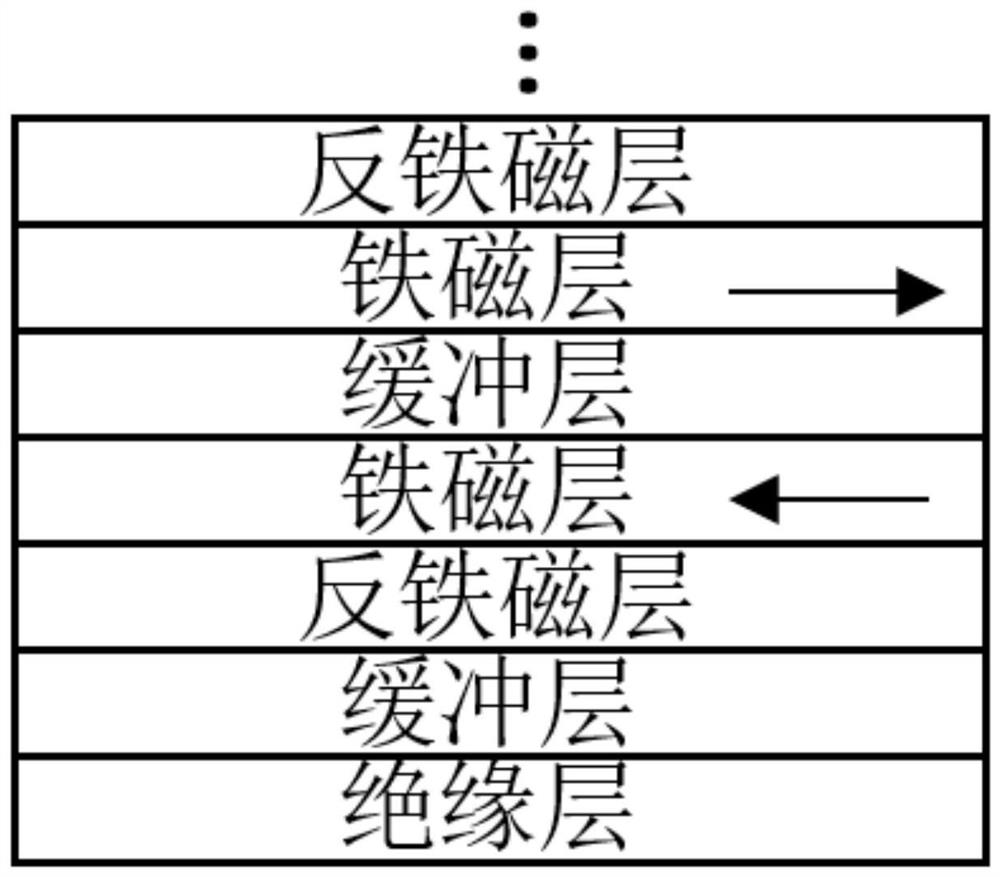

[0027] The on-chip magnetic core power inductor whose inductance value changes with the working current provided in this embodiment is prepared on a silicon chip by MEMS technology; the winding is made of metallic copper material with a thickness T c 12μm, width w c is 25μm, the coil gap g is 15μm; the width of the anisotropic magnetic core film W m =445μm, length L m =575 μm; the magnetic core film adopts [insulating layer / buffer layer / antiferromagnetic layer (AF) / ferromagnetic layer (FM) / buffer layer / ferromagnetic layer (FM) / antiferromagnetic layer (AF)] n Multi-layer film structure; insulating layer is SiO 2 The thin film is prepared by DC magnetron sputtering method: the sputtering power is 100-200W, the sputtering pressure is 0.2-0.7Pa, and the deposition time is controlled so that SiO 2 The thickness of the film is 4-10nm; the buffer layer is Cu metal thin film, which is prepared by DC magnetron sputtering method: the sputtering power is 25-60W, the sputtering pressur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com