Hydrolysis method of polymeric proanthocyanidins and product and application thereof

A technology of high-polymer procyanidin and oligomeric proanthocyanidin is applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, pharmaceutical formulations, etc. lower problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

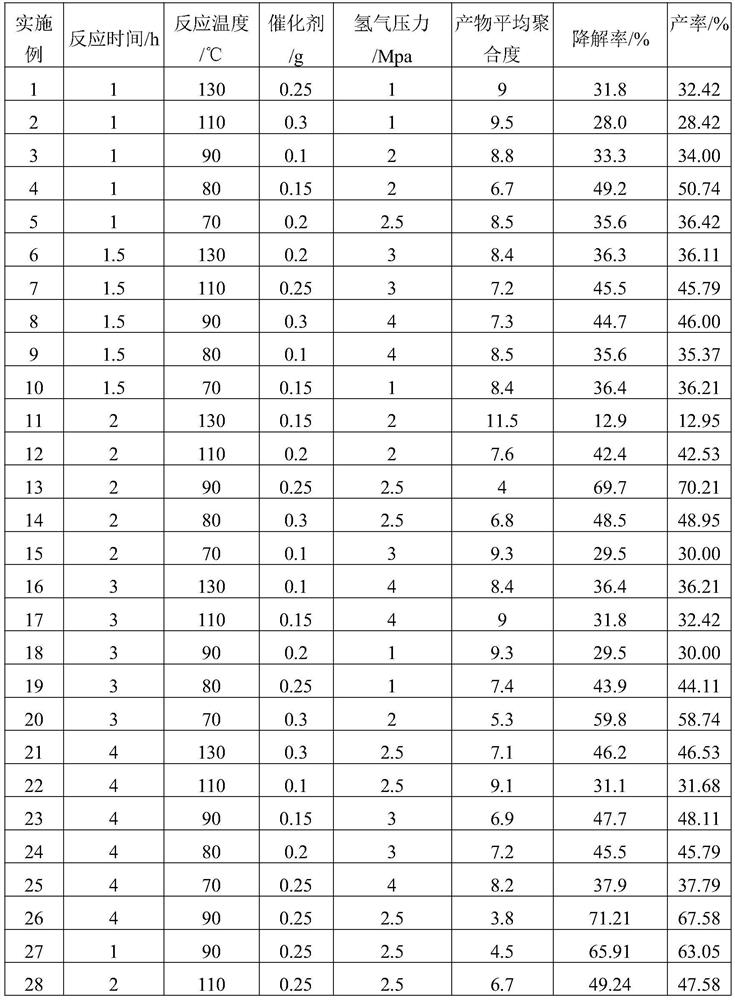

Examples

preparation example Construction

[0020] Preparation of Highly Aggregated Proanthocyanidins from Larix Bark

[0021] Extraction method was used to extract the high polyproanthocyanidins from the bark of pine leaf. Weigh 30 g of ground larch bark, add 300 mL of 70% (V / V) ethanol solution, reflux in a water bath at 80°C for 2 h, and collect the filtrate by filtration while it is hot. Add 210mL of 70% (V / V) ethanol solution to the filter residue, reflux extraction in a water bath at 80°C for 1 hour, and filter. The filtrates were combined to obtain an extract. Add petroleum ether (60-90) to the extract at a volume ratio of 1:1 to remove impurities such as resins and gums in the extract to obtain a purified solution. Use a rotary evaporator (45 ± 5) °C to recover the ethanol in the purified solution under reduced pressure, and filter to remove the red insoluble matter to obtain a concentrated solution. An equal volume of ethyl acetate was added to the concentrated solution for a total of 6 extractions. Obtain ...

Embodiment

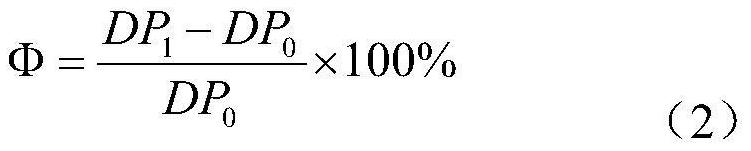

[0040] Weigh 0.5g polyproanthocyanidins and add 53.6g [BMIM]Cl (about 50mL), heat and dissolve under magnetic stirring at 90°C, after the dissolution is complete, add the mixed material and a certain amount of Pd / C catalyst into the hydrogenolysis reaction kettle , feed hydrogen, set the temperature and stirring speed at 500r / min, after the temperature in the reactor reaches the experimental temperature, turn on the rotor and start stirring, count the time, and start the reaction. After the reaction is finished, the reactant is taken out, the Pd / C solid catalyst is removed by filtration, and the reaction product LHPC is obtained, and the degradation effect of proanthocyanidins is represented by the degradation rate, and the degradation rate is calculated according to formula (2). Put the reaction product into a dialysis bag and dialyze for 72h, wash and dry to separate the degradation product.

[0041]

[0042] in: -Degradation rate

[0043] DP 1 - average degree of pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com