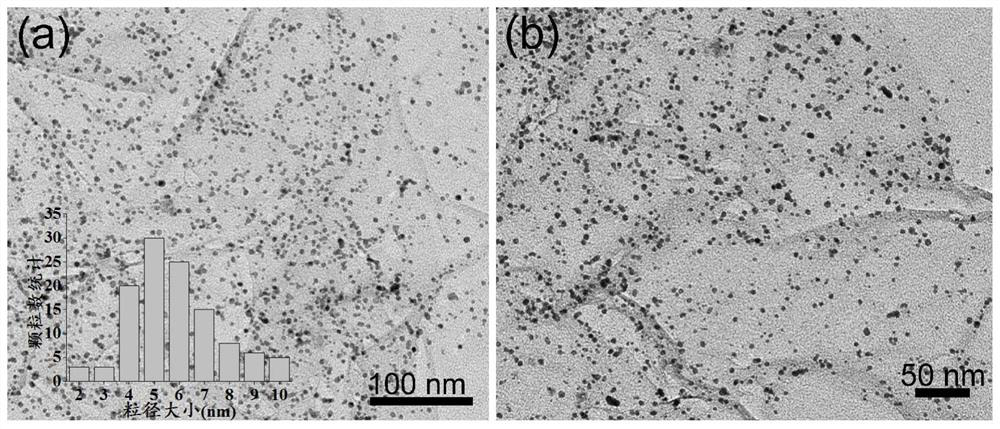

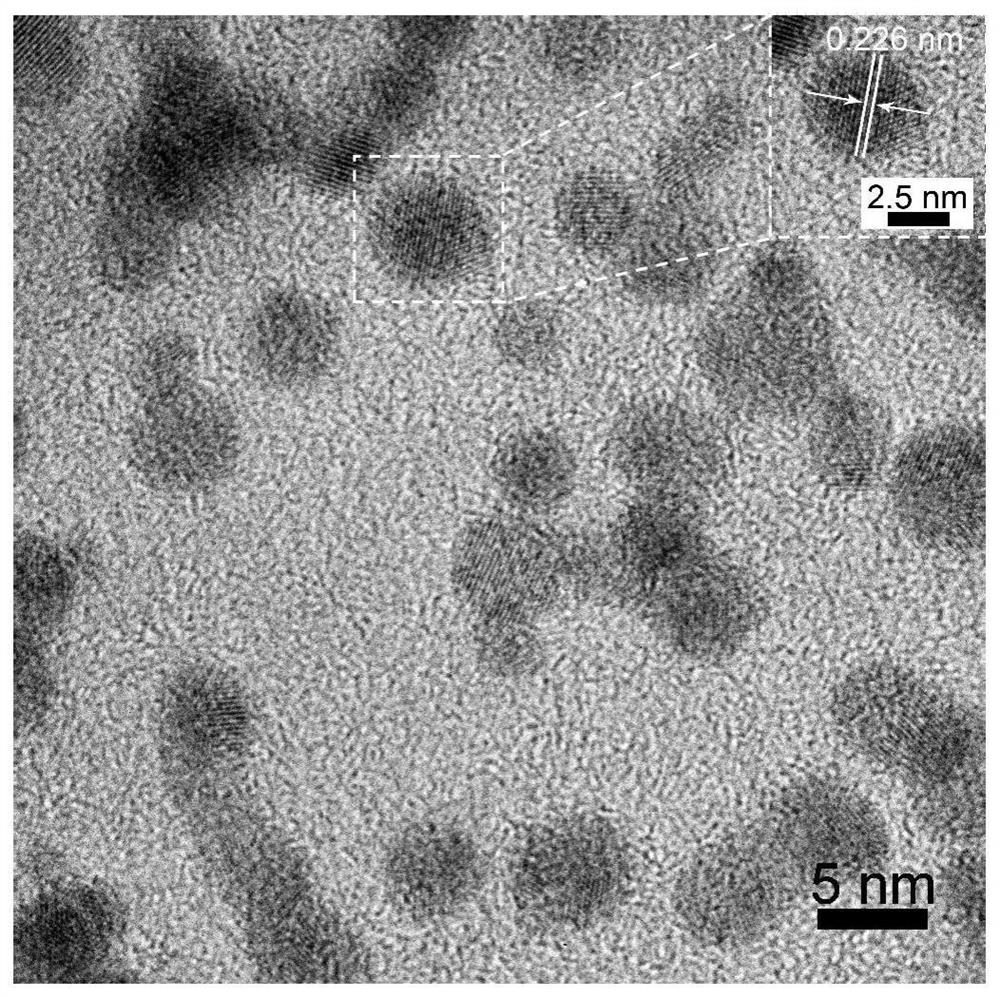

Preparation of supported CuPd bimetallic catalyst and application of supported CuPd bimetallic catalyst in oxidative coupling reaction

A bimetallic catalyst, supported technology, used in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, organic chemistry, etc., can solve the problem of low yield and high price of oxidative coupling reaction products. problems, to achieve good catalytic activity and stability, reduce dosage, and improve the effect of catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of supported CuPd bimetallic catalyst of the present invention, comprises the steps:

[0041] S1: Take 0.015-0.020mol / L sodium chloropalladate (Na 2 PdCl 4 ), 0.015-0.020mol / L copper chloride (CuCl 2 2H 2 (2) solution joins in the round bottom flask A, and magnetic stirring makes sodium chloropalladate and cupric chloride completely uniformly mix, and solution is transparent reddish-brown;

[0042] S2: Add the pre-prepared graphene oxide (GO) and deionized water into the round bottom flask B, and sonicate it until the graphene oxide is completely dissolved in the deionized water, and the solution is muddy yellow;

[0043] S3: Add the graphene oxide aqueous solution in the round bottom flask B dropwise into the round bottom flask A, so that the graphene oxide aqueous solution is uniformly mixed with sodium chloropalladate and copper chloride solution;

[0044]S4: adjust the pH value of the mixed solution in the flask of step S3 to 8-9 with sodi...

Embodiment 1

[0049] S1: Take 10mL 0.017mol / L sodium chloropalladate (Na 2 PdCl 4 ), 10mL 0.017mol / L copper chloride (CuCl 2 2H 2 O) solution joins in the 100mL round-bottomed flask A, and magnetic stirring makes sodium chloropalladate and cupric chloride completely uniformly mix, and the solution is transparent reddish-brown.

[0050] S2: Add 10 mg of graphene oxide (GO) prepared in advance and 20 mL of deionized water into a 100 mL round-bottom flask B, and sonicate it for 2 h until graphene oxide is completely dissolved in deionized water, and the solution turns muddy yellow.

[0051] S3: Add the graphene oxide aqueous solution in round-bottom flask B to round-bottom flask A drop by drop, at a rate of about 60 drops per minute, ultrasonic treatment while adding, and continue ultrasonication for 1 hour after the addition to make graphene oxide The aqueous solution is uniformly mixed with sodium chloropalladate and copper chloride solution.

[0052] S4: Adjust the pH value of the mixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com