Drill bit

A drill bit and head technology, which is applied in the field of rock drilling tools, can solve the problems of rock dust at the bottom of the hole, drill bit damage, micro-cracks, etc., and achieve the effects of reducing heat accumulation, improving service life, and preventing accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

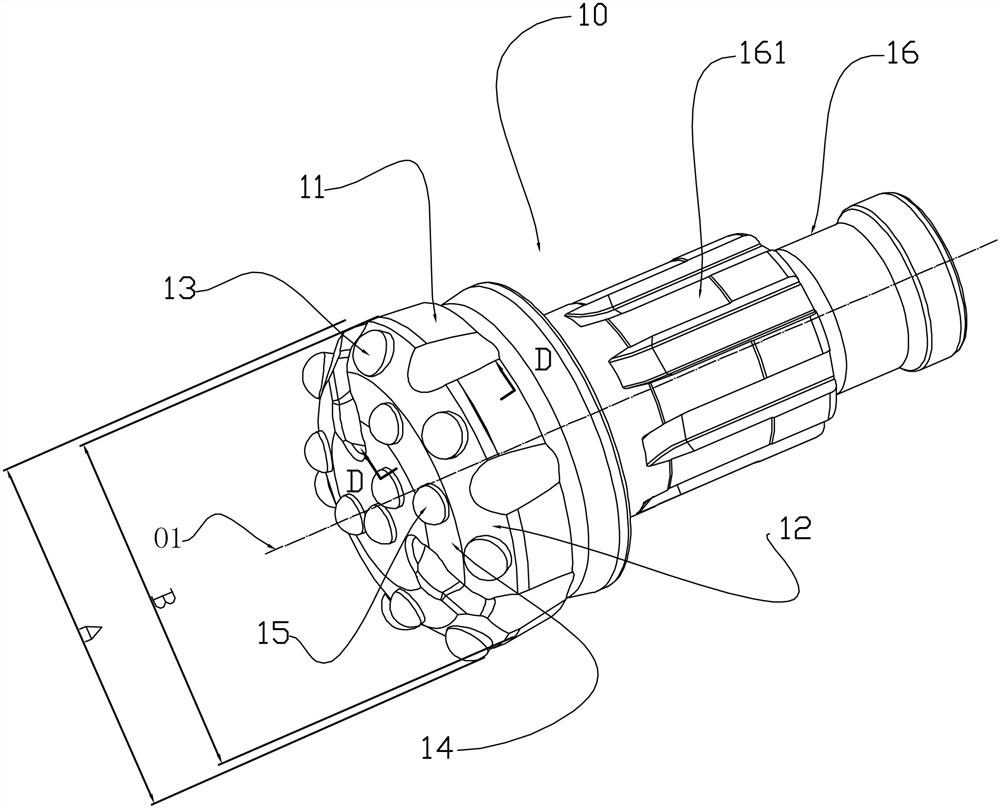

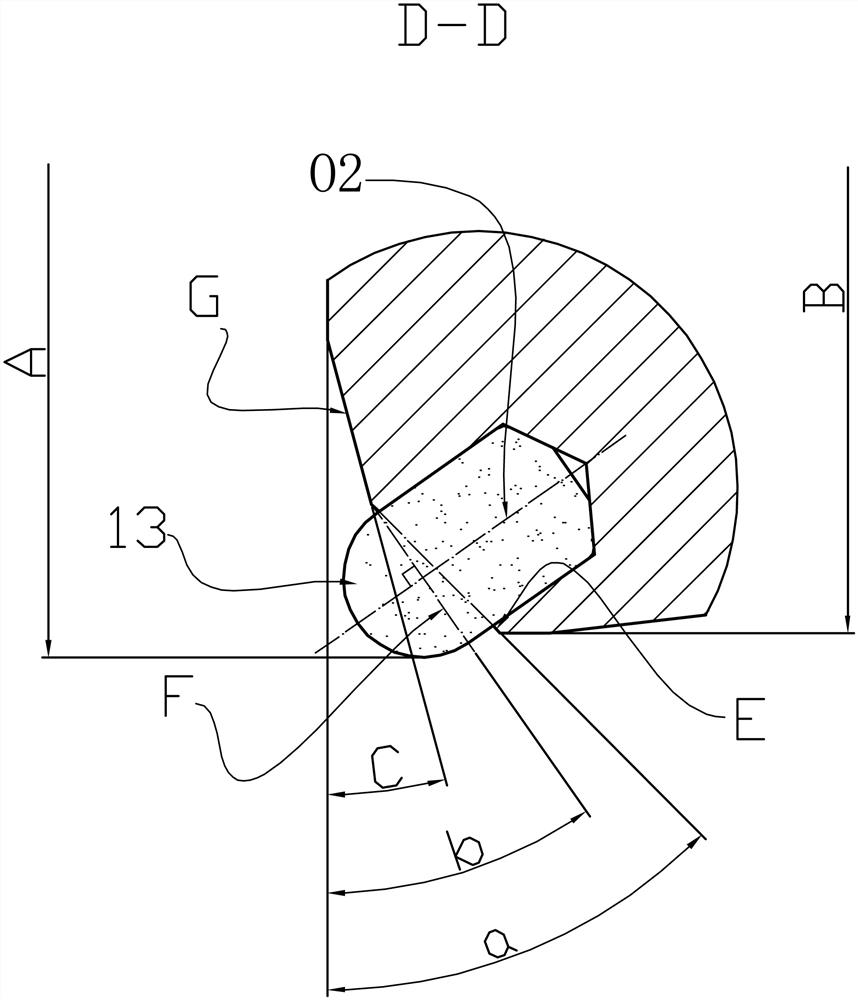

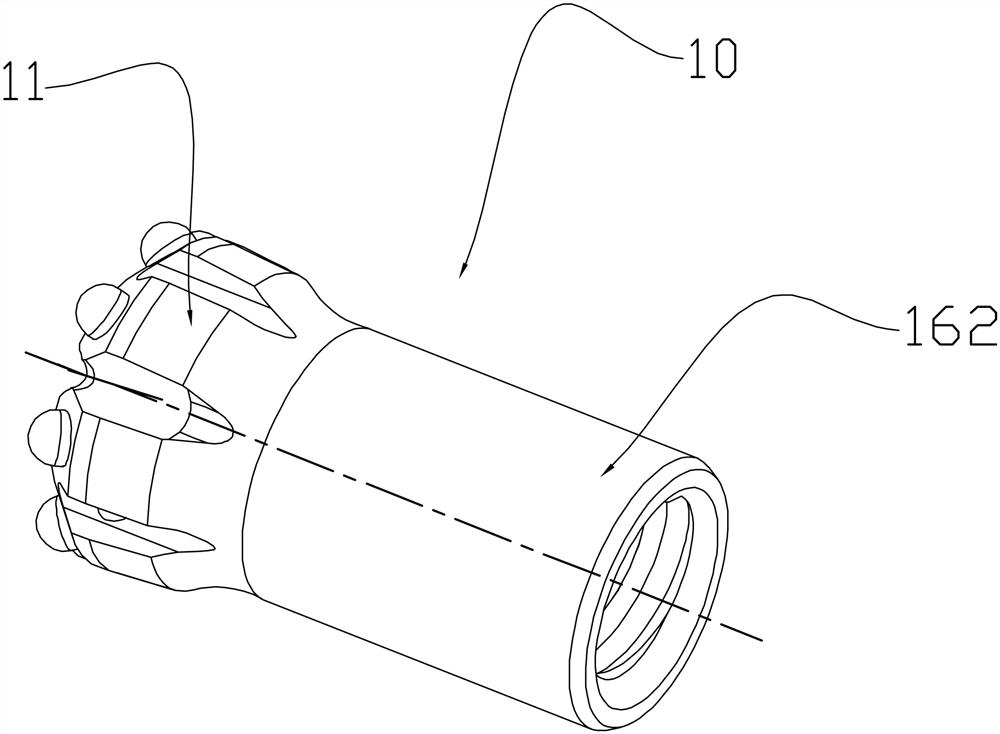

[0032] Such as Figure 1-3 , a drill bit, the drill bit 10 includes a head 11, the head 11 is provided with a first cone surface 12; the first cone surface 12 is provided with a first rock-breaking unit 13; The rock unit 13 completes the cutting of the outer rock at the bottom of the hole by the rotation of the drill bit 10 around its first axis O1; the first generatrix E of the first conical surface 12 forms a first included angle a with the end surface of the head 11; perpendicular to The section F of the second axis O2 of the first rock-breaking unit 13 forms a second angle b with the end surface of the head 11; and the value of the first angle a is always greater than the value of the second angle b; all the individual The second axis O2 of the first rock-breaking unit 13 is respectively in the same plane as the first axis O1 of the drill bit 10 ; By adopting the above drill bit structure and the corresponding angle value, the frictional hot spot of the first rock-breakin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com