Aluminum alloy corrosion resistance strengthening process combining regression reaging and subzero treatment

A technology of regressive reaging and cryogenic treatment, which is applied in the field of corrosion resistance strengthening combined with regressive reaging and cryogenic treatment of aluminum alloys. It can solve problems such as the lack of cryogenic treatment processes for aluminum alloys, and improve mechanical properties, corrosion resistance, and treatment quality. Good, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

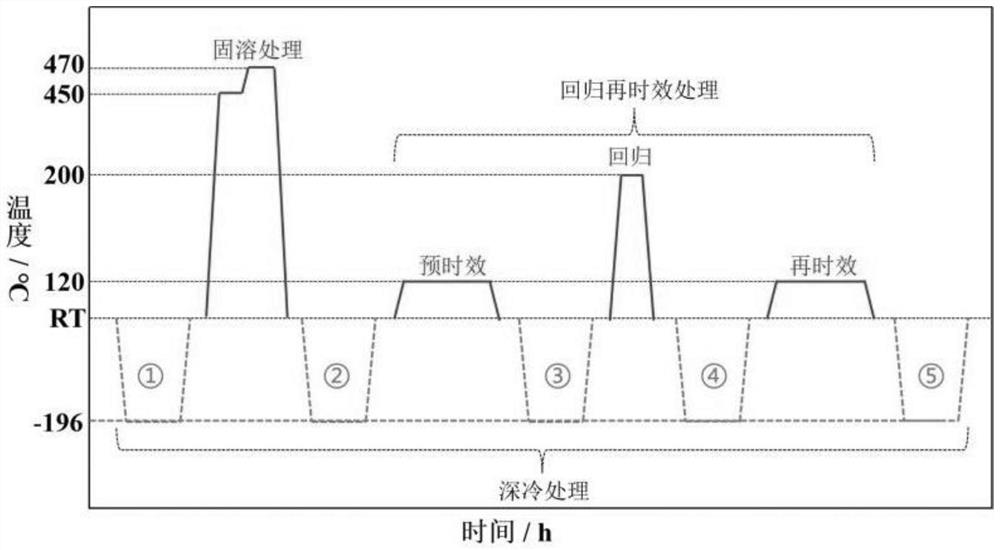

[0057]Step 1. Polish the aluminum alloy workpiece with a thickness of 0.5mm to a metallic luster with No. 2000 sandpaper, polish it with 1000-8000 mesh polishing paste, and place it on the workbench;

[0058] Step 2. Heat up the box-type resistance furnace to 450°C. After the temperature is stable, put the 7xxx series aluminum alloy into the furnace, and perform solid solution treatment on the aluminum alloy. The solid solution treatment time is 1 hour, and the furnace temperature is monitored by a potentiometer. The error of the furnace temperature is controlled within ±2°C; for quenching treatment, use deionized water at a temperature of 0-5°C, and the transfer time is within 2s;

[0059] Step 3. Put it into a digital display blast drying oven for aging treatment, and keep it warm for 12 hours at 120°C;

[0060] Step 4. Put it into a digital display blast drying oven for aging treatment, and keep it warm at 180°C for 8 minutes;

[0061] Step 5. Put it into a digital display...

Embodiment 2

[0064] Step 1. Polish the aluminum alloy workpiece with a thickness of 0.5mm to a metallic luster with No. 2000 sandpaper, polish it with 1000-8000 mesh polishing paste, and place it on the workbench;

[0065] Step 2, subject the alloy to cryogenic treatment, put it into liquid nitrogen, and keep it at -196°C for 10h;

[0066] Step 3. Heat up the box-type resistance furnace to 450°C. After the temperature is stable, put the 7xxx series aluminum alloy into the furnace, and perform solid solution treatment on the aluminum alloy. The solid solution treatment time is 1 hour, and the furnace temperature is monitored by a potentiometer. The error of the furnace temperature is controlled within ±2°C; for quenching treatment, use deionized water at a temperature of 0-5°C, and the transfer time is within 2s;

[0067] Step 4. Put it into a digital display blast drying oven for aging treatment, and keep it warm at 100°C for 16 hours;

[0068] Step 5. Put it into a digital display blast ...

Embodiment 3

[0072] Step 1. Polish the aluminum alloy workpiece with a thickness of 0.5mm to a metallic luster with No. 2000 sandpaper, polish it with 1000-8000 mesh polishing paste, and place it on the workbench;

[0073] Step 2. Heat up the box-type resistance furnace to 470°C. After the temperature is stable, put the 7-series aluminum alloy into the furnace, and perform solution treatment on the aluminum alloy. The solution treatment time is 2 hours, and the furnace temperature is monitored by a potentiometer. The error of the furnace temperature is controlled within ±2°C; for quenching treatment, use deionized water at a temperature of 0-5°C, and the transfer time is within 2s;

[0074] Step 3, subject the alloy to cryogenic treatment, put it into liquid nitrogen, and keep it at -196°C for 10h;

[0075] Step 4. Put it into a digital display blast drying oven for aging treatment, and keep it warm for 12 hours at 120°C;

[0076] Step 5. Put it into a digital display blast drying oven fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com