Radiation refrigeration self-cleaning coating

A radiation cooling and self-cleaning technology, applied in the direction of reflective/signal coatings, conductive coatings, coatings, etc., can solve problems such as unsatisfactory long-term effects, decline in radiation cooling effects, dust pollution on the coating surface, etc., to achieve good self-cleaning Cleaning effect, long-term stable cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

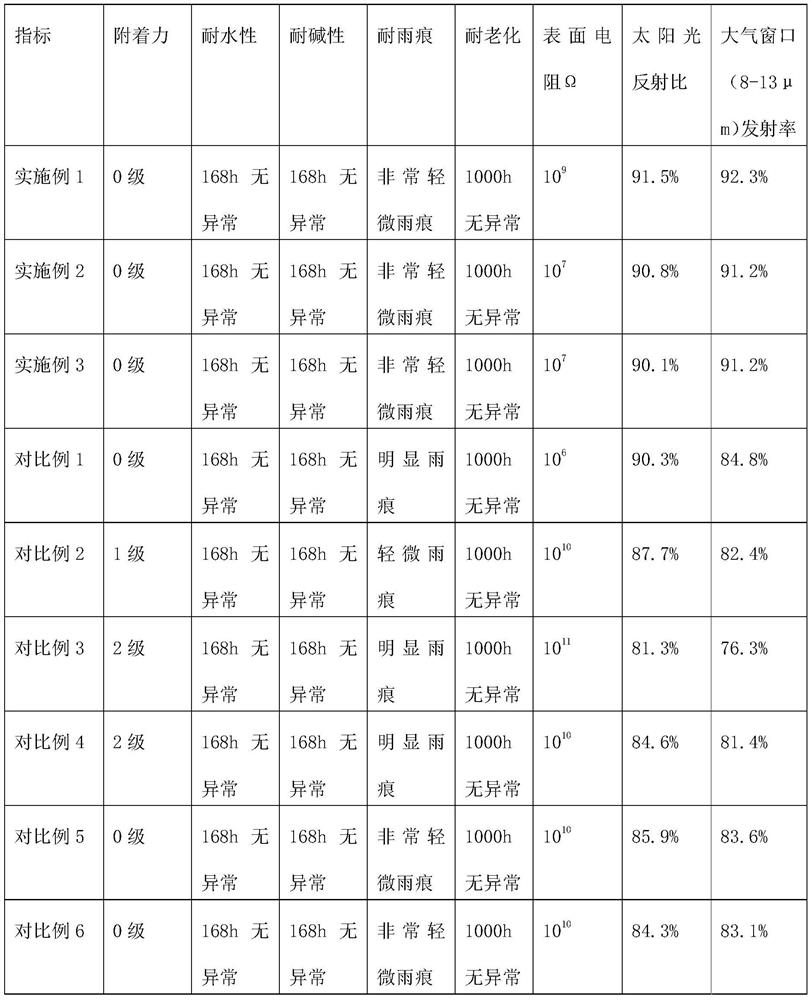

Embodiment 1

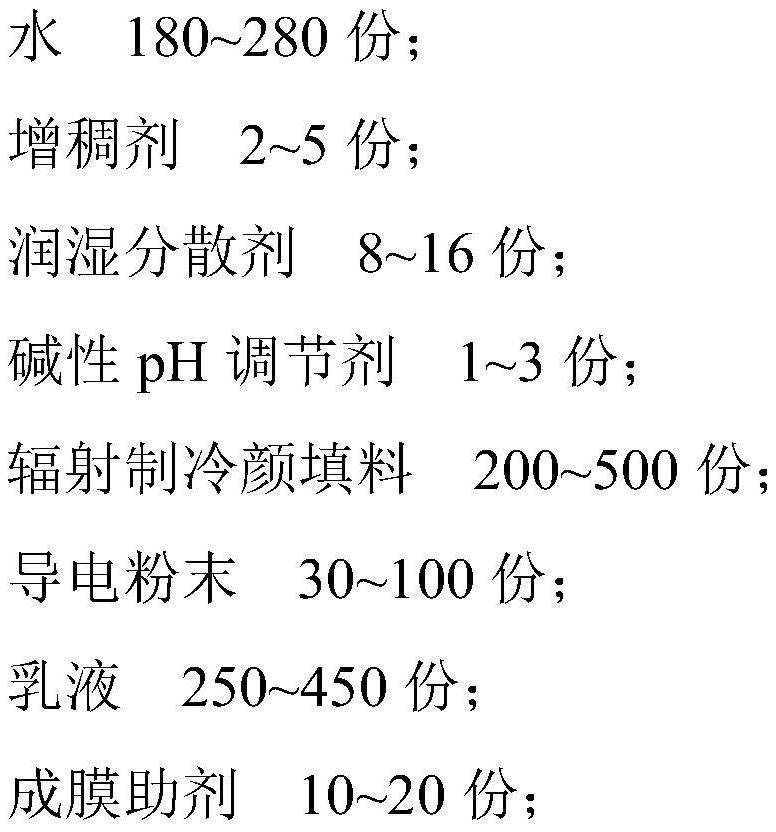

[0073] This example provides a high-performance radiative cooling self-cleaning coating, including the primer and top coat, and the raw materials are prepared according to the following ratio:

[0074] (1) Primer coating: 180Kg of water, 2Kg of thickener, 6Kg of defoamer, 16Kg of wetting and dispersing agent, 1Kg of pH regulator, 500Kg of radiant cooling filler, 30Kg of conductive powder, 250Kg of emulsion, and 15Kg of film-forming aid.

[0075] The thickener is associative polyurethane thickener: associative alkali-swellable thickener: hydroxyethyl cellulose ether at a ratio of 2:1:2.

[0076] Among them, the radiation cooling filler is titanium dioxide with high infrared reflectivity: the ratio of nano-alumina is 1:1.

[0077] Wherein the conductive powder is conductive titanium dioxide.

[0078] The emulsion is silicone acrylic emulsion.

[0079] Among them, the film-forming aid alcohol ester twelve: propylene glycol butyl ether: dipropylene glycol dimethyl ether is 8:4:3...

Embodiment 2

[0085] This example provides a high-performance radiative cooling self-cleaning coating, including the primer and top coat, and the raw materials are prepared according to the following ratio:

[0086] (1) Primer coating: 220Kg of water, 3Kg of thickener, 4Kg of defoamer, 12Kg of wetting and dispersing agent, 2Kg of pH regulator, 280Kg of radiant cooling filler, 49Kg of conductive powder, 320Kg of emulsion, 10Kg of film-forming aid, curing agent 100Kg.

[0087] Among them, the thickener is preferably an associative polyurethane thickener: water-based bentonite at a ratio of 3:2.

[0088] Among them, the radiation refrigeration filler nano-alumina: nano-zinc oxide: ceramic powder is 4:4:1.

[0089] Among them, the ratio of conductive powder conductive titanium dioxide: tin oxide powder is 6:1.

[0090] The emulsion is preferably a hydroxyl acrylic emulsion (hydroxyl value ≤ 100): the curing agent ratio is 3.2:1.

[0091] Alcohol ester twelve: propylene glycol diacetate: dipr...

Embodiment 3

[0097] This example provides a high-performance radiative cooling self-cleaning coating, including the primer and top coat, and the raw materials are prepared according to the following ratio:

[0098] (1) Primer coating: 280Kg of water, 5Kg of thickener, 3Kg of defoamer, 8Kg of wetting and dispersing agent, 3Kg of pH regulator, 200Kg of radiant cooling filler, 90Kg of conductive powder, 400Kg of emulsion, and 11Kg of film-forming aid.

[0099] Among them, the thickener is preferably an associative polyurethane thickener: water-based bentonite: associative alkali-swellable thickener at a ratio of 3:2:1.

[0100] Among them, the ratio of radiative cooling filler high infrared reflection titanium dioxide: ceramic powder is 8:1.

[0101] Among them, the conductive powder conductive titanium dioxide: conductive mica powder: tin oxide powder is 1:2:1.

[0102] The emulsion is an acrylic emulsion.

[0103] Alcohol ester twelve: propylene glycol butyl ether is 4:1.

[0104] (2) To...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com