Shading water-based ink and preparation method thereof

A technology of water-based ink and water-based polyurethane, which is applied in ink, household utensils, applications, etc., can solve the problems of polluting the ecological environment and endangering human health, and achieve the effects of saving energy, reducing production costs, and improving viscosity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

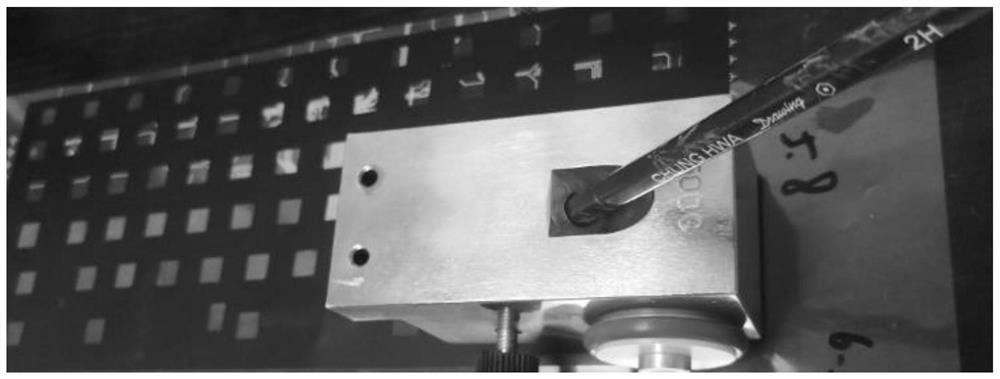

Image

Examples

Embodiment 1

[0045] A water-based light-shielding ink, in parts by mass, comprising:

[0046]Polyethylene glycol isophthalate 39.8 parts; Polyethylene terephthalate 17.2 parts; Trimethylolpropane 6 parts; Dimethylethanolamine 1.8 parts; Fatty alcohol polyoxyethylene ether (AE0-9) 1 part; 0.4 part of water-based polyether modified silicone leveling agent (Xinbocheng, SP-941); 0.2 part of polyether modified silicone defoamer; 0.2 part of 2,6-di-tert-butyl-p-cresol 8.4 parts of ethylene glycol butyl ether; 0.2 parts of N-methylpyrrolidone; 10 parts of isophorone; 26 parts of carbon black; 2.4 parts of talcum powder; 7.6 parts of barium sulfate; 78.8 parts of water.

[0047] In addition to trimethylolpropane, chain extenders can also use diethanolamine, triethanolamine, N-methyldiethanolamine, N-ethyldiethanolamine, N-propyldiethanolamine, N-butyldiethanolamine, dimethyl ethanolamine.

[0048] In addition to ethylene glycol butyl ether, alcohol ether solvents can also use ethylene glycol met...

Embodiment 2

[0061] A water-based light-shielding ink, in parts by mass, comprising:

[0062] Polyethylene glycol isophthalate 50 parts; Polyethylene terephthalate 16.6 parts; Trimethylolpropane 10 parts; Dimethylethanolamine 1 part; Fatty alcohol polyoxyethylene ether (AE0-9) 1.2 parts; 0.8 parts of water-based polyether modified silicone leveling agent; 0.4 parts of polyether modified silicone defoamer; 0.4 parts of 2,6-di-tert-butyl-p-cresol; 7 parts of ethylene glycol butyl ether; 0.6 parts of N-methylpyrrolidone; 8 parts of isophorone; 20 parts of carbon black; 4 parts of talcum powder; 10 parts of barium sulfate; 70 parts of water.

[0063] The preparation method is the same as in Example 1.

Embodiment 3

[0065] A water-based light-shielding ink, in parts by mass, comprising:

[0066] 44 parts of polyethylene isophthalate; 20 parts of polyethylene terephthalate; 16 parts of trimethylolpropane; 1.6 parts of dimethylethanolamine; fatty alcohol polyoxyethylene ether (AE0-9) 1.2 parts; 0.4 parts of water-based polyether modified silicone leveling agent; 0.2 parts of polyether modified silicone defoamer; 0.4 parts of 2,6-di-tert-butyl-p-cresol; 7.6 parts of ethylene glycol butyl ether; 4 parts of N-methylpyrrolidone; 5 parts of isophorone; 16 parts of carbon black; 8 parts of talcum powder; 6 parts of barium sulfate; 69.6 parts of water.

[0067] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com