Preparation method of waterborne epoxy resin dispersion

A technology of water-based epoxy resin and solid epoxy resin, which is applied in the direction of epoxy resin coatings and coatings, and can solve problems that affect the water and solvent resistance of the coating film, cannot maintain stability and performance, and cannot meet the development needs of coatings, etc. , to achieve good storage stability and dilution stability, excellent chemical resistance, convenient transportation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

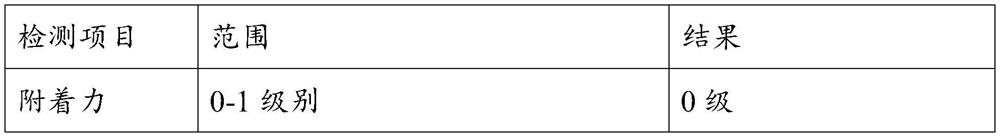

Examples

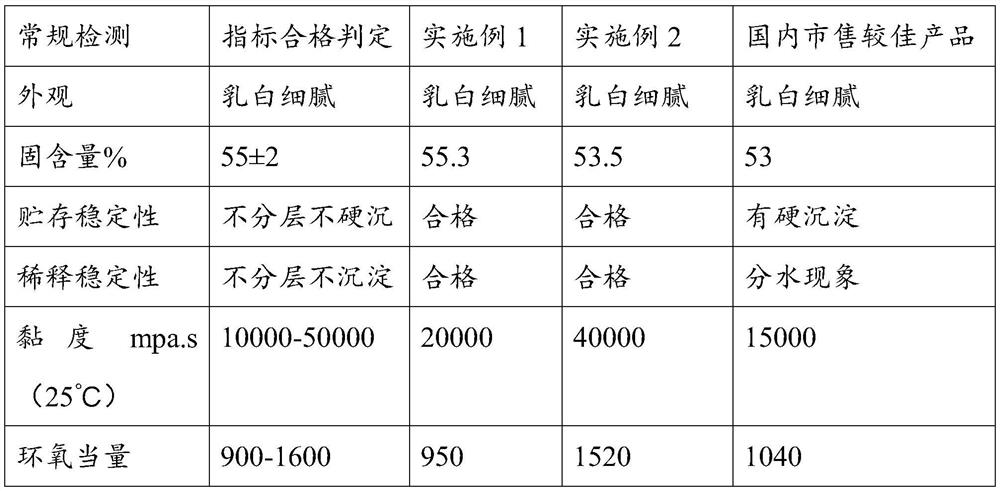

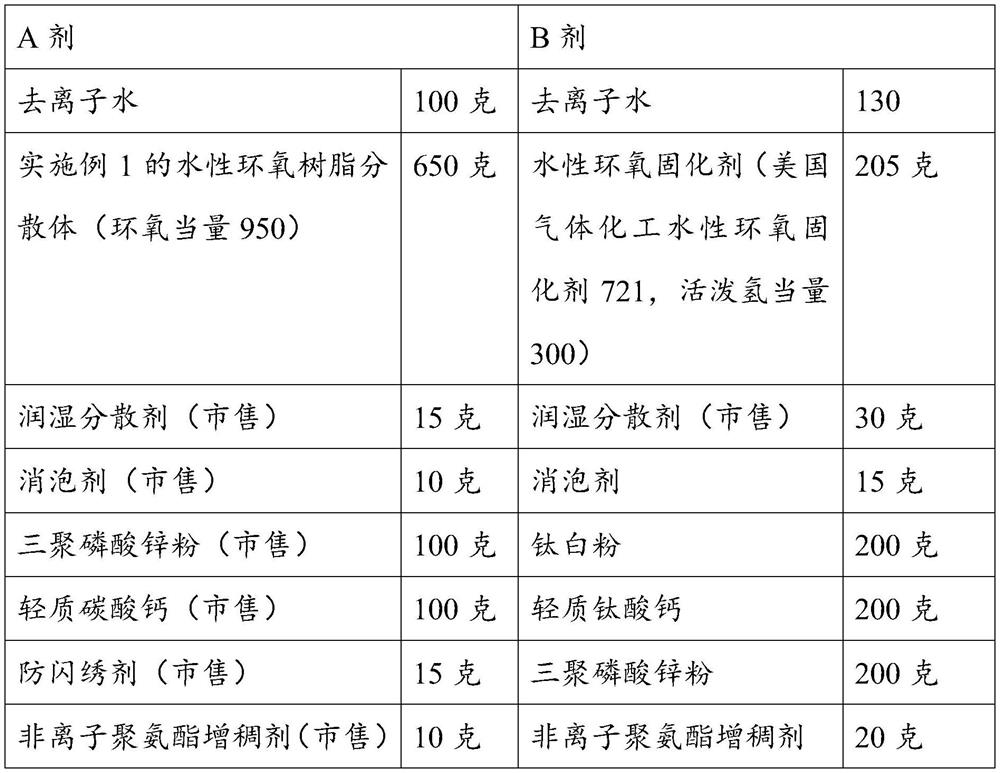

Embodiment 1

[0025] The operation steps are as follows:

[0026] 1. Add 3000 grams of hydrophilic polyethylene glycol propylene glycol copolymer (PEG / PPG-17 / 6 copolymer) into the four-necked flask, start stirring and raise the temperature to 100°C, and start vacuuming to remove the moisture in the system , kept for 1h, stopped when there were no small bubbles in the four-necked flask, and then lowered the temperature to 70°C.

[0027] 2. Add 20 grams of catalyst boron trifluoride diethyl ether into the four-necked flask, stir for 10 min, then slowly add 900 grams of solid epoxy resin E-20 dilution (mass fraction is 70% solid ring Oxygen resin content of xylene dilution), 1h dropwise, the temperature was kept at 70 ° C for 2-3h.

[0028] 3. Add 15 grams of catalyst boron trifluoride diethyl ether into the four-neck flask, stir for 10 minutes, slowly add 92 grams of epichlorohydrin dropwise, after 1-2 hours, keep the reaction at 80-85°C for 3 hours.

[0029] 4. Raise the temperature to 110...

Embodiment 2

[0034] The operation steps are as follows:

[0035] 1. Add 5000 grams of hydrophilic polyethylene glycol propylene glycol copolymer (PEG / PPG-25 / 30 copolymer) into the four-necked flask, start stirring and raise the temperature to 100°C, and start vacuuming to remove the moisture in the system , kept for 1h, stopped when there were no small bubbles in the four-necked flask, and then lowered the temperature to 70°C.

[0036] 2. Add 30 grams of catalyst N, N dimethylbenzylamine to the four-necked flask, stir for 10 min, then slowly add 1600 grams of solid epoxy resin E-12 dilution (mass fraction is 70 % solid epoxy resin content of xylene dilution), 1h dropwise, the temperature was maintained at 70 ° C for 2-3h.

[0037] 3. Add 20 grams of catalyst N,N dimethylbenzylamine into the four-necked flask, stir for 10 minutes, slowly add 95 grams of epichlorohydrin dropwise, and dropwise for 1-2 hours, keep the reaction at 80-85°C for 3 hours .

[0038] 4. Raise the temperature to 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com