Method for rapidly separating lignin with high yield by using green solvent

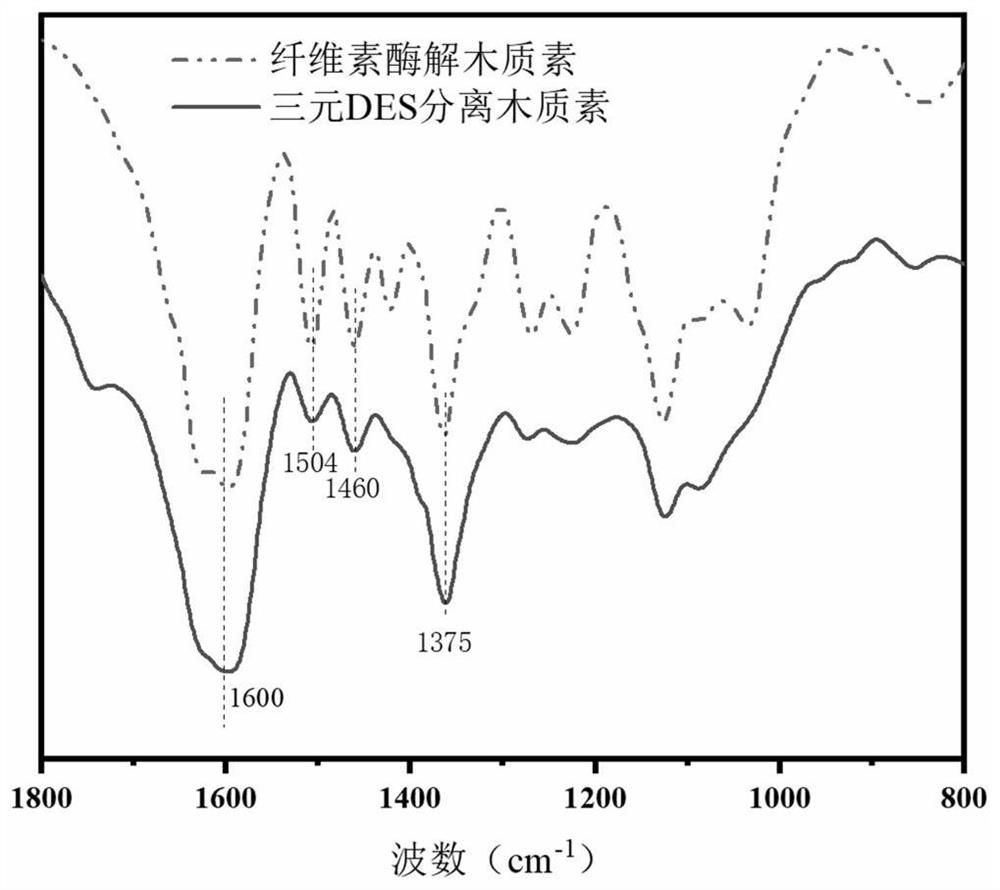

A green solvent, high-yield technology, applied in the field of lignin separation, can solve the problems of high energy consumption, long separation time, large molecular weight of lignin, etc., and achieve the effects of simple process operation, environmental friendliness and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Weigh choline chloride, glyoxylic acid and p-toluenesulfonic acid in a three-necked flask with a molar ratio of 1:2:0.05, heat and stir at 60°C to obtain a homogeneous transparent liquid, which is the deep eutectic solvent (DES) , cooled to room temperature and stored in a desiccator. Weigh 2.00 grams of red poplar wood powder (40-60 mesh) and 20 milliliters of DES into a three-necked flask, and react at 120° C. for 20 minutes. After the reaction, the slurry is poured into 60 milliliters of 50% acetone aqueous solution, and stirred at room temperature for 3 hours. Centrifuge to obtain residue one and supernatant one. The residue one was washed until the washing liquid was colorless, and the supernatant one and the washing liquid were combined and then concentrated to 30 ml. 15 ml of tetrahydrofuran was added to the concentrated solution, and the extraction was repeated three times. Afterwards, the extracts were combined and concentrated to 15 ml, added to 150 ml of sa...

Embodiment 2

[0032]Weigh choline chloride, glyoxylic acid and p-toluenesulfonic acid in a three-necked flask with a molar ratio of 1:2:0.03, heat and stir at 60°C to obtain a homogeneous transparent liquid, which is the deep eutectic solvent (DES) , cooled to room temperature and stored in a desiccator. Weigh 2.00 grams of red poplar wood powder (40-60 mesh) and 20 milliliters of DES into a three-necked flask, react at 120° C. for 120 minutes, pour the slurry into 60 milliliters of 50% acetone aqueous solution after the reaction, stir at room temperature for 3 hours, and Centrifuge to obtain residue one and supernatant one. The residue one was washed until the washing liquid was colorless, and the supernatant one and the washing liquid were combined and then concentrated to 30 ml. 15 ml of tetrahydrofuran was added to the concentrated solution, and the extraction was repeated three times. Afterwards, the extracts were combined and concentrated to 15 ml, added to 150 ml of saturated salin...

Embodiment 3

[0034] Weigh choline chloride, glyoxylic acid and p-toluenesulfonic acid in a three-necked flask with a molar ratio of 1:2:0.05, heat and stir at 60°C to obtain a homogeneous transparent liquid, which is the deep eutectic solvent (DES) , cooled to room temperature and stored in a desiccator. Weigh 2.00 grams of red poplar wood powder (40-60 mesh) and 20 milliliters of DES into a three-necked flask, react at 100° C. for 120 minutes, pour the slurry into 60 milliliters of 50% acetone aqueous solution after the reaction, stir at room temperature for 3 hours, and Centrifuge to obtain residue one and supernatant one. The residue one was washed until the washing liquid was colorless, and the supernatant one and the washing liquid were combined and then concentrated to 50 ml. 20 ml of tetrahydrofuran was added to the concentrated solution, and the extraction was repeated three times. Afterwards, the extracts were combined and concentrated to 30 ml, added to 300 ml of saturated sali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com