Composite floor and ecological board base material and production process thereof

A technology of composite flooring and ecological boards, which is applied to wood processing appliances, manufacturing tools, and the joining of wooden veneers. It can solve problems such as inconsistent pressure on the base material, irreparable internal core material, and difficult control of moisture content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

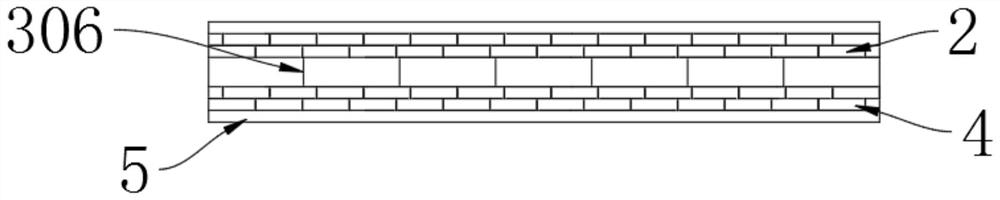

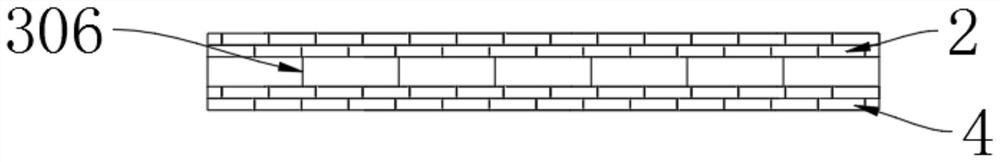

[0037] see Figure 1-11, an ecological board base material, including a core substrate 3, the core substrate 3 includes a core panel 306, an insertion rod 308 and an insertion block 302, the top left side of the core panel 306 is provided with a dovetail groove A303, and the core panel 306 Dovetail groove B304 is provided on the right side of the top of the core panel 306, and dovetail groove C309 is provided on the right side of the bottom of the core panel 306. The left side and the right side of the core puzzle 306 are provided with jacks 307, and inserting rods 308 are arranged in the jacks 307. The front and rear sides of the core puzzle 306 are all provided with slots 301, and inserting blocks are inserted in the slots 301. 302 , the front and rear sides of several core panels 306 are spliced by inserting blocks 302 , and the inner insertion holes 307 of several core panels 306 are connected through insertion rods 308 .

[0038] A composite floor made of ecological bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com