Flour cake screening and removing device

A technology for agglomeration and flour, which is applied in the field of equipment for screening and removing flour agglomerates, can solve the problems of failure to reach flour processing plants, secondary screening, poor screening effect, etc., and achieve convenient screening, convenient operation, and better screening effect good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] A flour cake screening removal device, such as figure 1 As shown, including the first fixing frame 1, the second fixing frame 2, the third fixing frame 3, the filter mechanism 4, the discharge mechanism 5, and the push mechanism 6, and the second fixing frame 2 on the left and right side are provided. Two first fastener 1, the inner wall of the two first fasteners 1 is provided with a third fixing frame 3, and the top of the third fixing frame 3 on both sides is provided with a filter mechanism 4, two first fixing frame 1. There is a discharge mechanism 5, and a push mechanism 6 is provided on both first fasted frames 1.

[0074] When people need to screen the cake flour, this flour cake screening can be used to remove the removed device, and first, people need to pour the cake flour into the discharge mechanism 5, and put the collected frame on the ground, then drive the discharge mechanism. 5 Back movement, so that the cake flour falls into the filter mechanism 4, the dis...

Embodiment 2

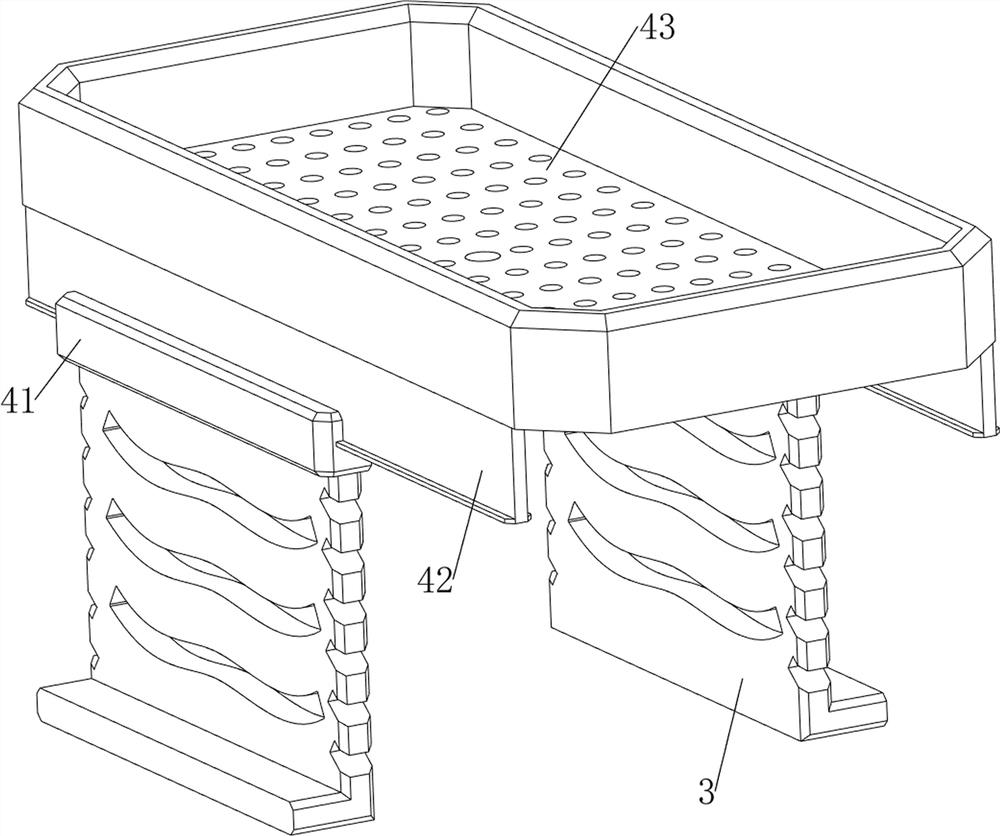

[0076] On the basis of Example 1, such as Figure 2- Figure 4 As shown, the filter mechanism 4 includes a first slide rail 41, a slide plate 42, and a filter frame 43, and both sides of the third fixing frame 3 are provided with a first slide rail 41, and the two first sliding rails 41 are slid. A sliding plate 42 is provided, and a filter frame 43 is provided between the top of the two sliding plates 42.

[0077] When the knot flour falls to the filter frame 43, people push the flow of about 43 to move the slide plate 42, so that the filter frame 43 sways, which can filter the cake of flour, so that the spread flour In the collection box, the effect of filtration is achieved.

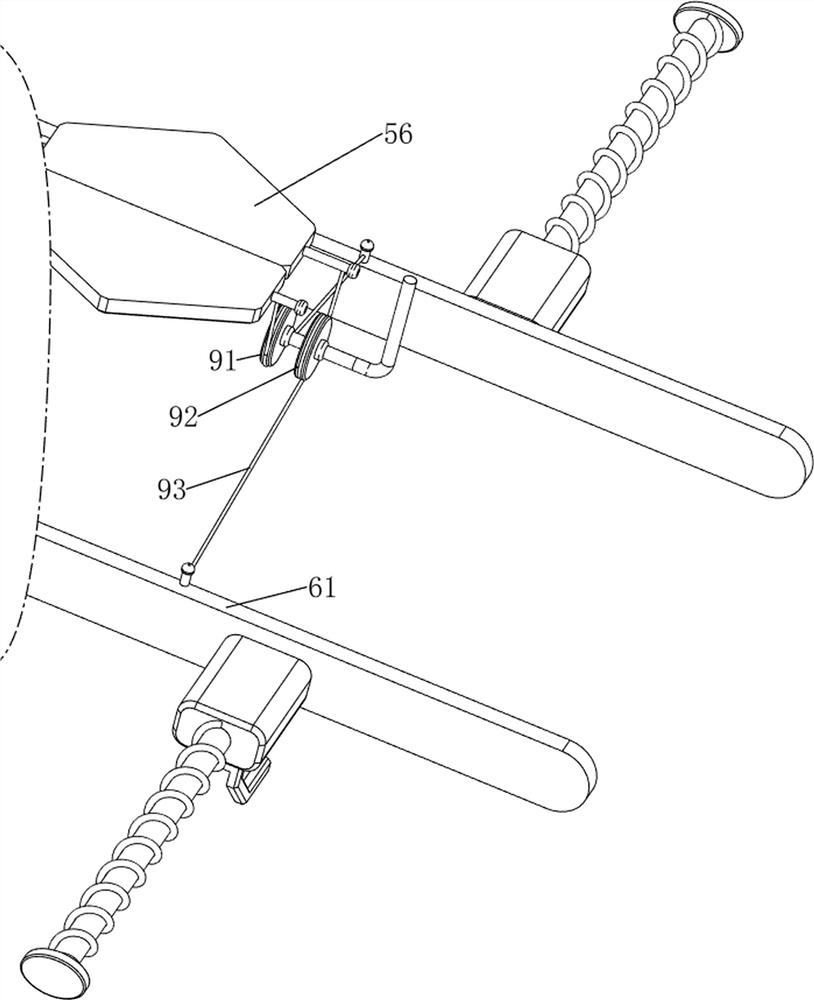

[0078] The discharge mechanism 5 includes a fourth fixing frame 51, a tank 52, a fifth fixation frame 53, a curved rail 54, a curved spring 55, a valve 56, a first fixing shaft 57, and a guide rod 58, two first The mounting frame 1 is provided with a fourth fixing frame 51, and there is a tank 52 between th...

Embodiment 3

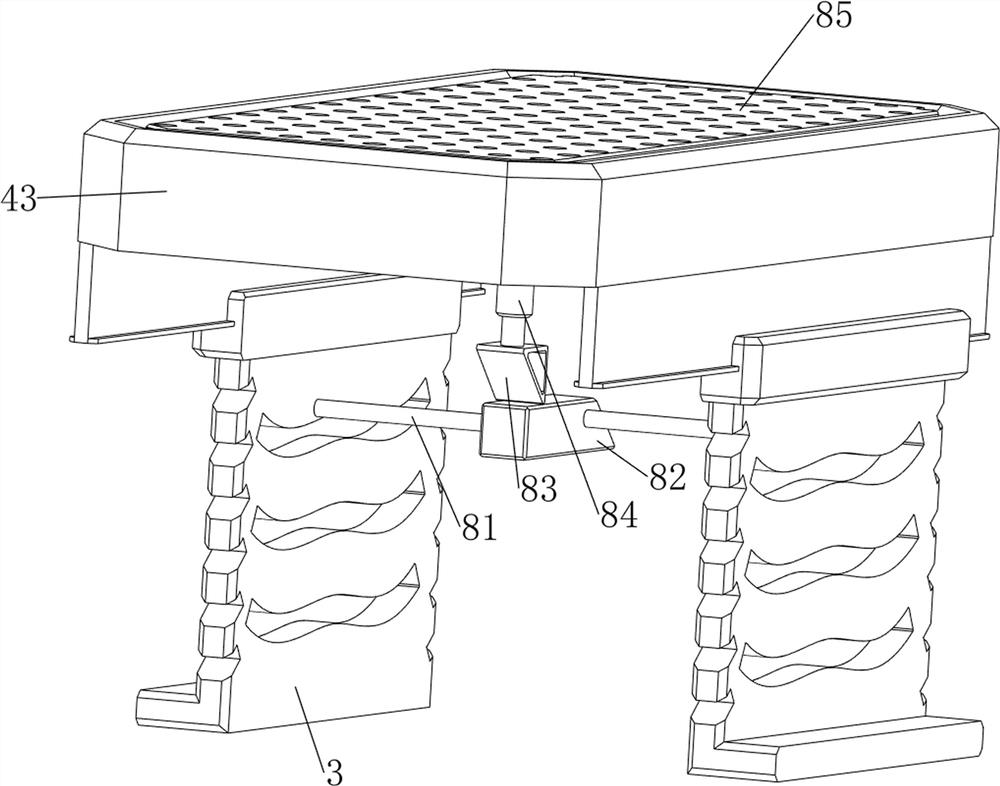

[0083] On the basis of Example 2, such as Figure 5 - Figure 8 As shown, there is a jitter mechanism 7, the jitter mechanism 7 includes a seventh fixing frame 71, a motor 72, an eighth fixing frame 73, a pulley group 74, a curved arm 75, and a link 76, a first fixation frame 1. The seventh fixing frame 71 is provided in the right portion, and the top of the seventh fixing frame 71 is attached, and the first fixing frame 1 in the front side is provided with the eighth fixation frame 73, the eighth fixation frame 73 upper rotation type. An arms 75 are provided having a link 76 on both sides of the right portion of the curved arm 75, and the connecting rod 76 is fixedly connected to the same side, and the output shaft of the motor 72 is connected between the intermediates of the arms 75. The leather belt set 74, the leather wheel group 74 consists of two pulley and belt, and one pulley is attached to the output shaft of the motor 72, and the other pulley is connected to the left side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com