Automatic corn stripping and breaking device

An automatic peeling, corn technology, applied in the direction of threshing equipment, applications, agricultural machinery and implements, etc., can solve the problems of corn husk peeling, corn husk peeling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

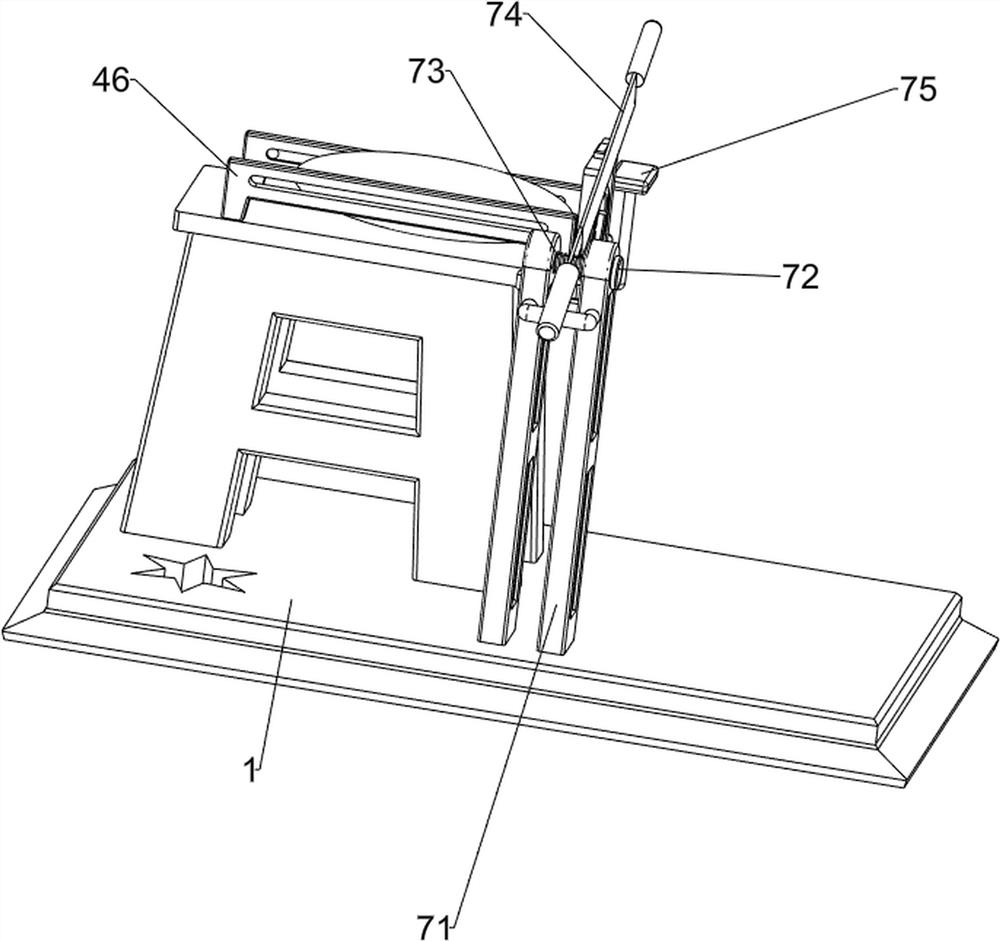

[0064]Automatic peel separation of corn devices, such asfigure 1 As shown, a base 1, a fixing frame 2, a collector 3, a feed mechanism 4, and a release mechanism 5 are provided, and a fixing frame 2 is provided on the left side of the base 1. The top of the base 1 is provided with a collector 3, and the fixing frame 2. A feeding mechanism 4 is provided between the top and the top of the base 1, and the upper right portion of the fastener 2 and the feed mechanism 4 is provided with a release mechanism 5.

[0065]When people need to peel off and cut off the corn skin, it is possible to use such automatic peeling to separate corn devices. First, the user needs to place corn on the fixing frame 2, and then start the feeding mechanism 4, the feed mechanism 4 drives corn to the right, when corn When the release mechanism 5 is exposed, the peeling mechanism 5 will peel the corn skin, and the peeling corn will fall into the collector 3, and it is not necessary to close the feed mechanism 4 whe...

Embodiment 2

[0067]On the basis of Example 1, such asfigure 2 ,image 3 As shown, the feed mechanism 4 includes a first bracket 41, a servo motor 42, a first number of axis 43, a turntable 44, a swing rack 45, a rail 46, and a push plate 47, and two first brackets 41 are provided on the top of the base 1. The servo motor 42 is attached to the top of the first bracket 41, and the output shaft of the servo motor 42 is connected between the first number of the rails 41 between the rear side, and the first axis 43 and the rear side of the first bracket 41 rotation type Connecting, a turntable 44 is provided on the rear side of the first rotating shaft 43, and both sides of the front and rear side of the fastener 2 are provided with a slide rail 47 between the two side slide 46, and the base 1 is in the middle of the left. The side rotation is provided with a wiper 45, the swing frame 45 is slidable with the push plate 47, and the left side of the turntable 44 is slidable with the swing frame 45.

[0068...

Embodiment 3

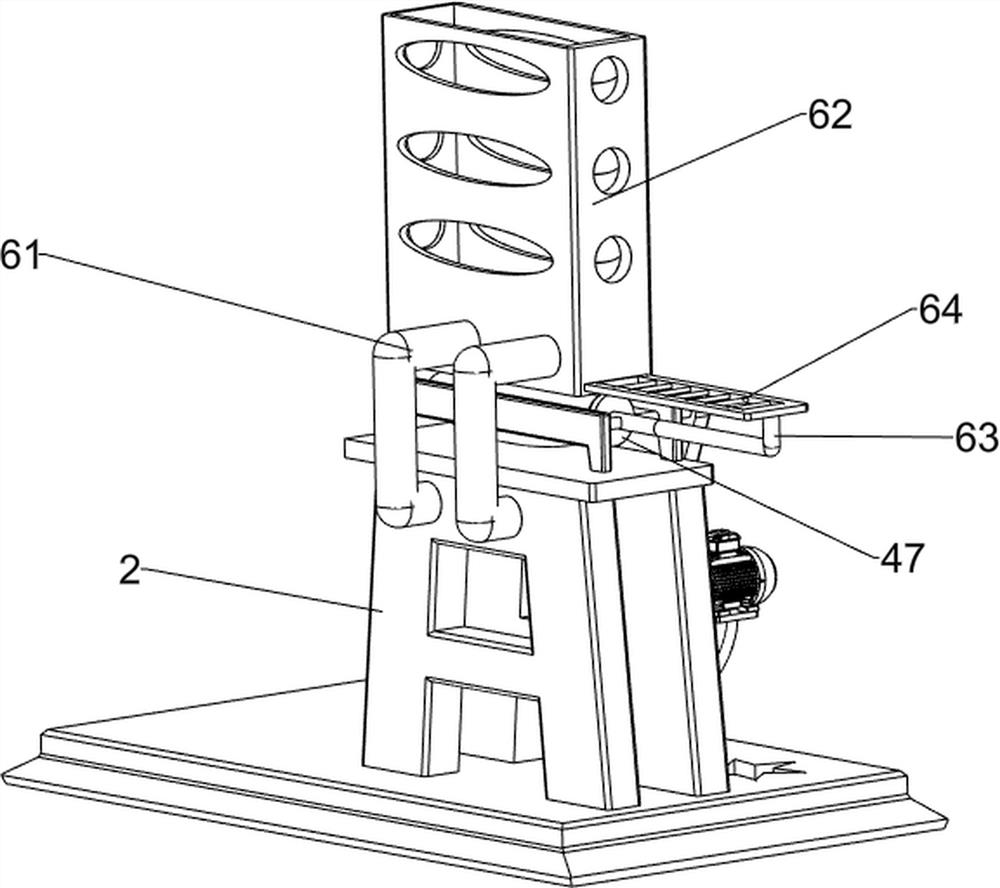

[0072]On the basis of Example 2, such asFigure 4 - Figure 7As shown, there is also a discharge mechanism 6, and the discharge mechanism 6 includes a secondary strut 61, a discharge box 62, a push rod 63, and a baffle 64, and two second sheets are provided on the upper side of the rear of the fastener 2. There is a discharge box 62 between the front side of the two secondary pillars 61, and a push rod 63 is provided on the left side of the push plate 47. The top end of the push rod 63 is provided with a baffle 64, and the baffle 64 is slid. Connection.

[0073]The user is placed in the discharge box 62 in the corn, and the push plate 47 will drive the push rod 63 to reciprocate, when the push plate 47 is moved to the left, the corn will fall from the discharge box 62 to the fixing frame 2. On the upper, while the push plate 47 is moved to the right, the baffle 64 can block corn so that corn does not fall into the fixing frame 2 to achieve a function of gap.

[0074]Also included include th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com