Electronic component surface oxide removing device

A technology for surface oxides and electronic components, applied in the field of surface oxide removal devices for electronic components, can solve problems such as affecting product quality and damage to electronic components, and achieve the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

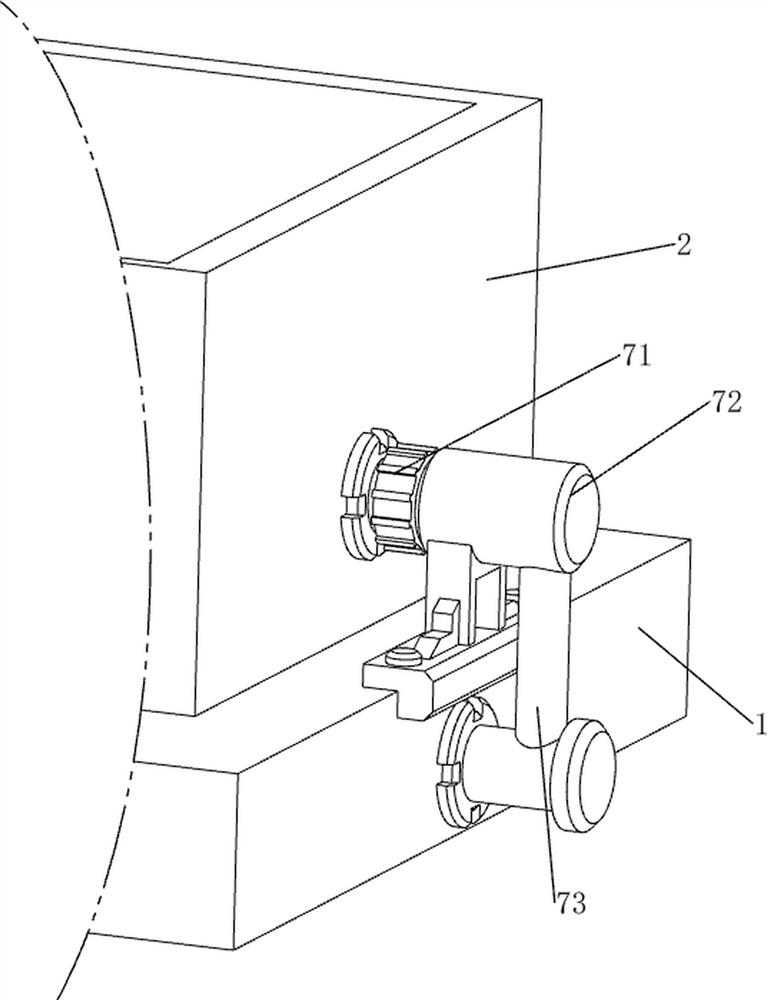

[0071] Such as Figure 1-2 As shown, a device for removing oxides on the surface of electronic components includes a first water tank 1, a second water tank 2, a derusting mechanism 4 and a feeding mechanism 5, the first water tank 1 is provided with a second water tank 2, and the second water tank 2 The upper side of the water tank 2 is provided with a derusting mechanism 4, and the derusting mechanism 4 is provided with a feeding mechanism 5.

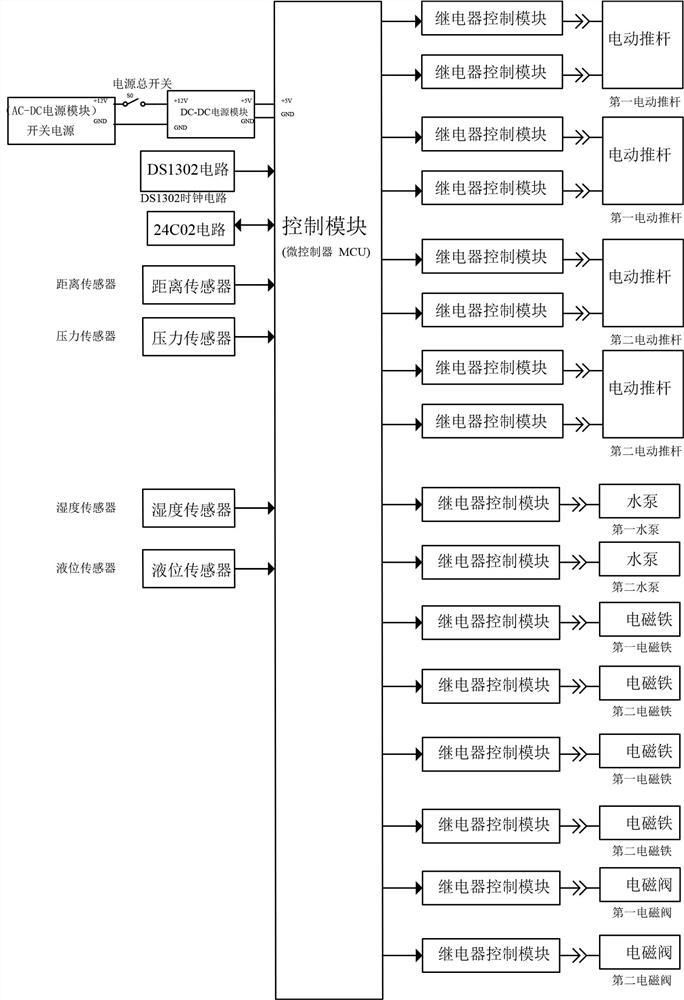

[0072] When people need to remove the surface oxide of electronic components, people need to press the main power switch to power on the device, and people need to pour the rust remover into the second water tank 2 first, and then put the electronic components in On the feeding mechanism 5, when the weight on the feeding mechanism 5 detected by the 5 parts of the feeding mechanism reaches the preset value in the control module, the 5 parts of the feeding mechanism send a signal, and the control module controls the operation of the fee...

Embodiment 2

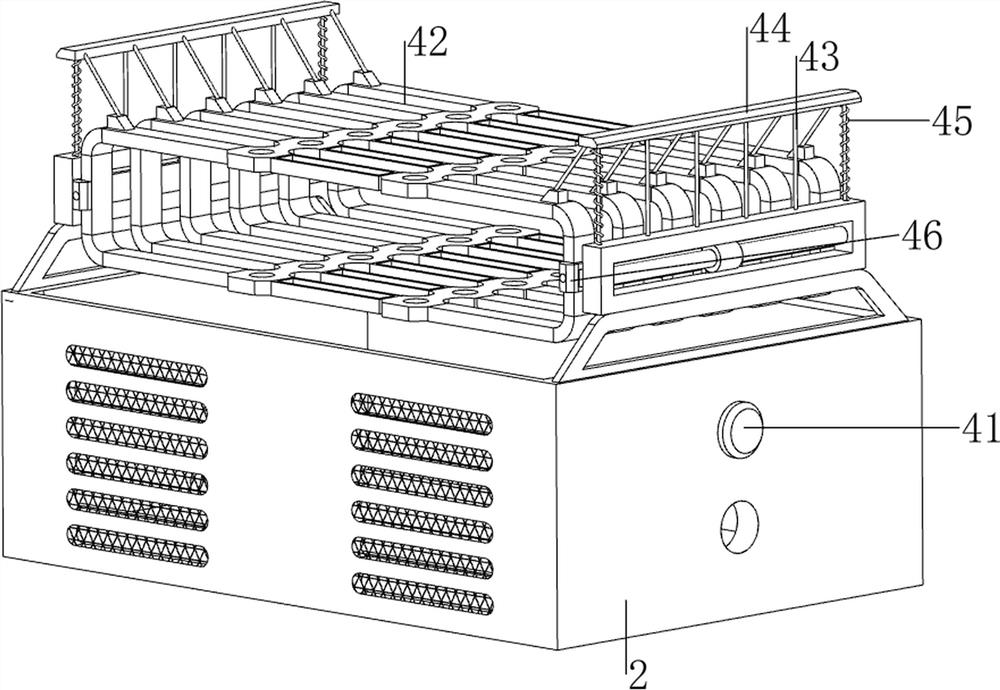

[0074] Such as Figure 3-17 As shown, the derusting mechanism 4 includes a liquid level sensor 41, a feeding part 42, a stay cord 43, a first electromagnet 44, a first spring 45, a magnetic block 46 and a sliding sleeve 47, and the outer wall of the second water tank 2 upper right side is arranged There is a liquid level sensor 41, and the left and right sides of the top of the second water tank 2 are slidingly provided with sliding sleeves 47, and the two sliding sleeves 47 are provided with magnetic blocks 46, and a feeding part 42 is arranged between the two magnetic blocks 46. Six stay cords 43 are connected between the left and right sides of the top of the discharge member 42 and the top of the second water tank 2, and the first electromagnet 44 is arranged between the six stay cords 43 on the same side in the longitudinal direction. The second water tank 2 cooperates, and the first spring 45 is all wound on the two stay cords 43 of the frontmost side and the two stay co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com