Part derusting device for engineering machinery

A technology for construction machinery and parts, applied in the field of rust removal devices for construction machinery parts, can solve the problems of easy rusting of iron parts, accelerated time for parts to rust, reduction in diameter, etc., and achieve the effect of rust removal and rust removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

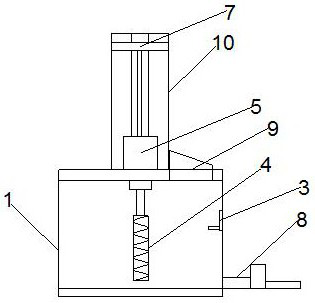

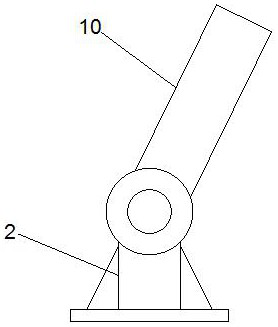

[0019] Combining with the derusting device for construction machinery parts shown in 1-3, it includes a lifting bracket and a derusting tank. The top end of the derusting bucket 1 is provided with a feeding port, and a feeding hopper is set on the feeding port. 9. There is a circular opening in the center of the top of the derusting bucket 1, and the lifting bracket is located on one side of the derusting bucket 1. The lifting bracket includes a mounting frame 2, and the mounting frame 2 is hinged by a rotating motor 6 Elevator 10 is arranged, and described elevator 10 comprises lifting platform 7, and the bottom of described lifting platform 7 is hung with stirring m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com