A variable diameter wire rope descaling device

A steel wire rope, variable technology, applied in the direction of grinding drive devices, manufacturing tools, grinding machine tool parts, etc., can solve the problems of scattered and inconvenient collection of steel wire ropes, achieve convenient collection, improve work efficiency, and avoid scattered effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

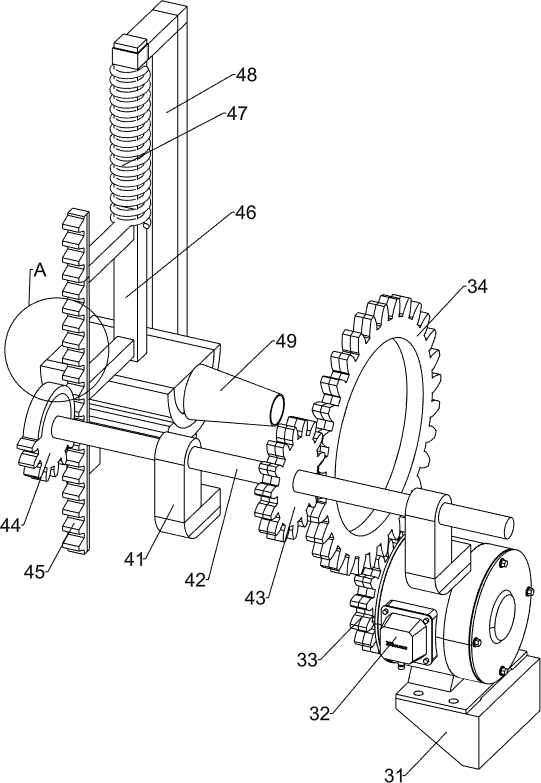

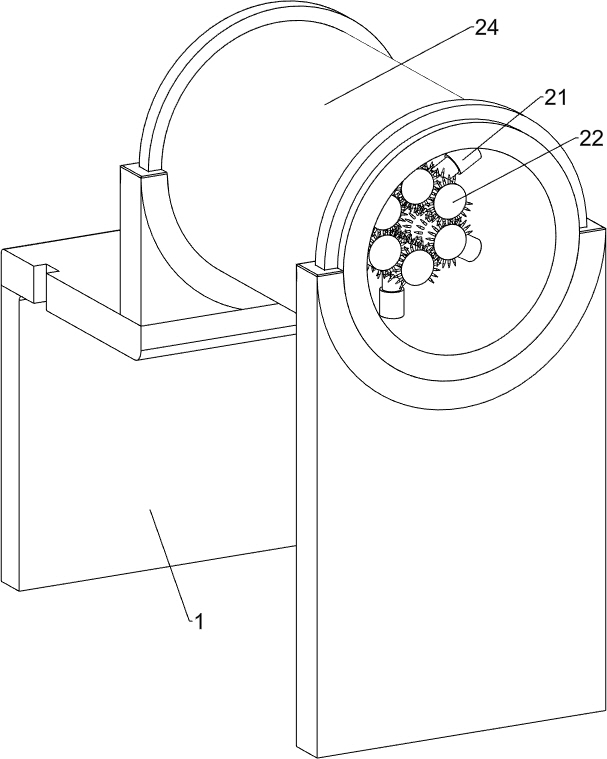

[0021] A variable-diameter steel wire rope derusting device, such as figure 1 As shown, it includes a mounting frame 1, a derusting mechanism 2 and a power mechanism 3. A derusting mechanism 2 is rotatably connected between the top of the mounting frame 1, and a power mechanism 3 is provided at the front and rear of the mounting frame 1. The power mechanism 3 and The derusting mechanism 2 is connected.

[0022] When people need to derust the steel wire rope, people pass the steel wire rope through the middle part of the rust removal mechanism 2, and then start the rotation of the parts of the power mechanism 3, and the rotation of the parts of the power mechanism 3 drives the rotation of the parts of the rust removal mechanism 2, and the rust removal mechanism 2 The rust on the steel wire rope is worn away by the rotation of the parts. After finishing the derusting of the steel wire rope, people close the parts of the power mechanism 3 so that the device no longer rotates, so ...

Embodiment 2

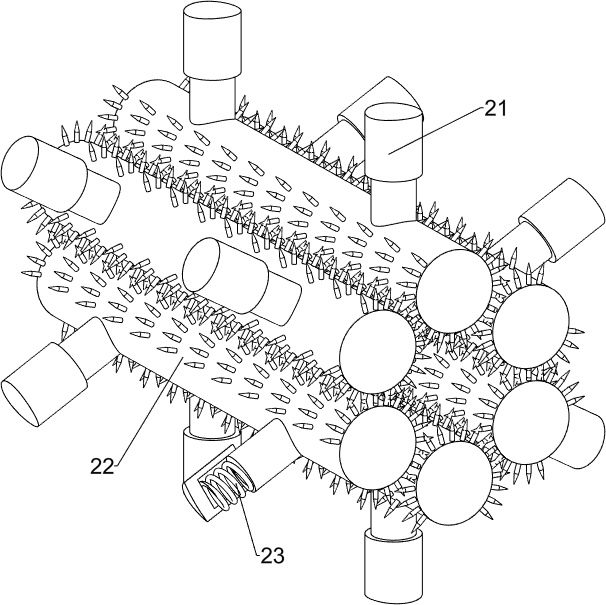

[0024] On the basis of Example 1, such as Figure 2-6 As shown, the derusting mechanism 2 includes a guide sleeve 21, a derusting rod 22, a first spring 23, and a roller 24. The roller 24 is connected in rotation between the top of the mounting frame 1, and the inner wall of the roller 24 is symmetrically arranged on both sides of the front and rear sides. The guide sleeve 21 is slidably connected with a derusting rod 22 between the guide sleeve 21 on the front side and the rear side, and a first spring 23 is connected between the inner wall of the guide sleeve 21 and the derusting rod 22 .

[0025] When people derust the steel wire rope, people pass the steel wire rope between the derusting rods 22. When the steel wire rope was relatively thick, the first spring 23 was compressed, and the wire rope was stuck between the derusting rods 22. When the steel wire rope was relatively thin , the first spring 23 resets, and the wire rope is stuck between the derusting rods 22. With t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com