A kind of molybdenum disulfide @ graphdiyne composite material, preparation method and application

A composite material, molybdenum disulfide technology, applied in the field of electrochemical energy storage, can solve the problems of low mass energy density, achieve low cost, small size, and increase the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

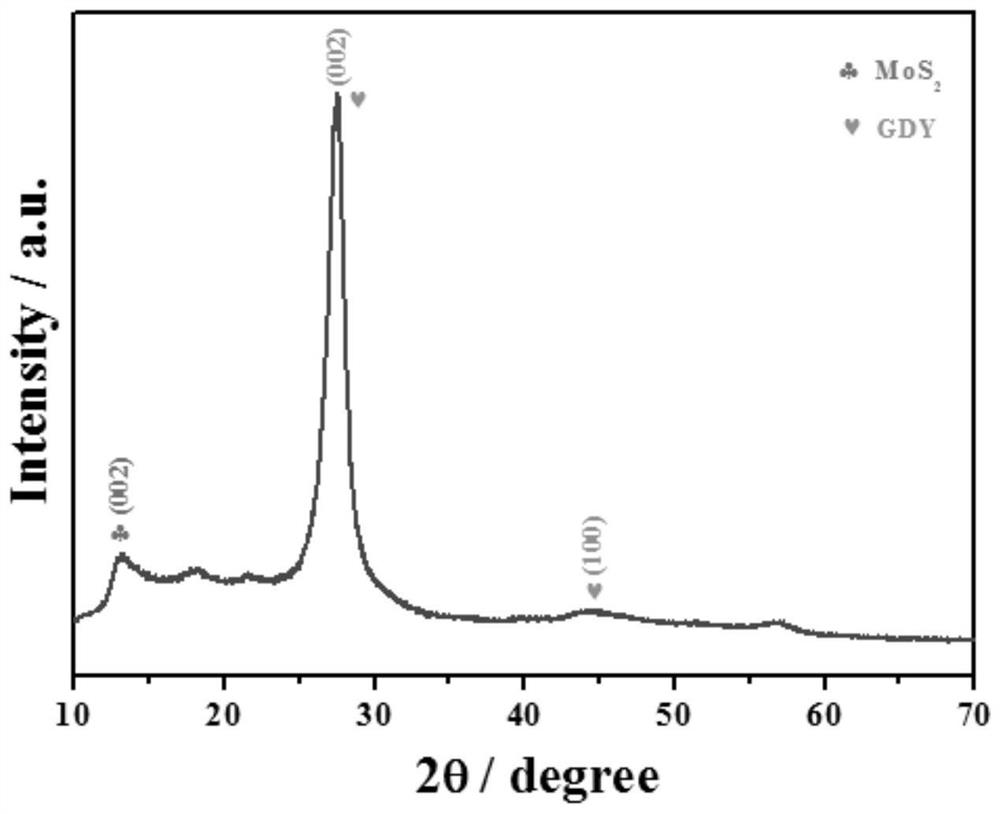

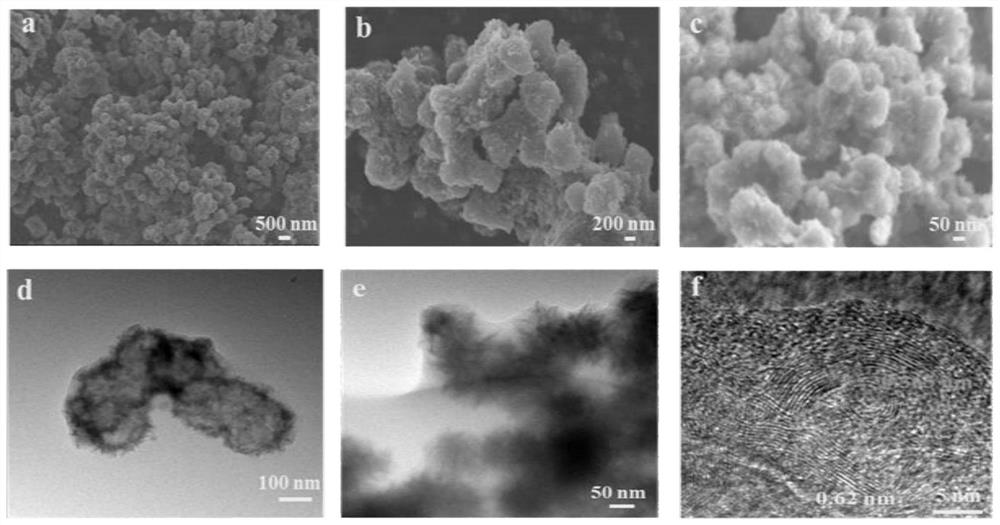

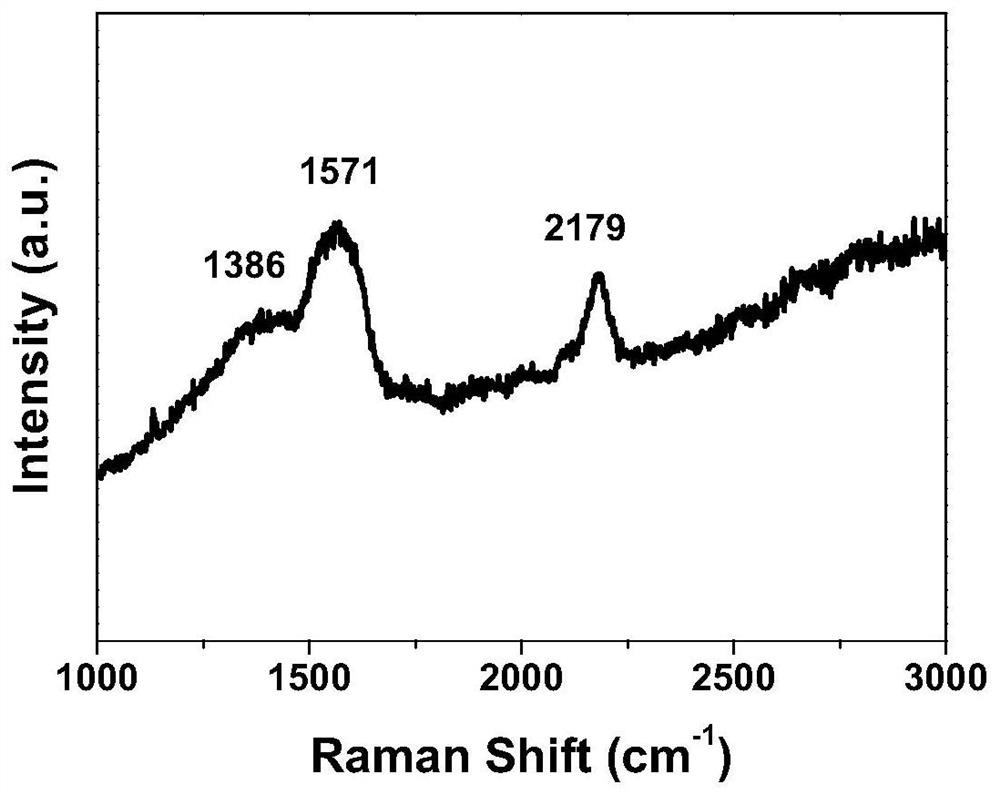

[0031] Preparation of MoS2@graphdiyne composites:

[0032] (1) Under a nitrogen atmosphere, 100 mg of hexa(trimethylsilyl-ethynyl)benzene (HEB-TMS) and 1 mL of tetra-n-butylammonium fluoride were sequentially added to a reaction flask containing 50 mL of dichloromethane (DCM). Trihydrate (TBAF), stirred at 0 °C for 15 min to obtain a mixture, then the above mixture was washed twice with 50 mL of deionized water, and then dried with anhydrous magnesium sulfate to obtain a hexaethynylbenzene solution.

[0033] (2) dropping the hexaethynylbenzene solution obtained in step (1) into a round bottle containing cobalt acetate and pyridine, wherein the addition ratio of the hexaethynylbenzene solution to cobalt acetate and pyridine is 1 mg / mL: 25 mg: 10 mL, The reaction was carried out at 40°C for 12h. After the reaction was completed, it was washed with pyridine, dimethylformamide, 1M HCl and deionized water in sequence, and dried to obtain graphdiyne (GDY) powder.

[0034] (3) addi...

Embodiment 2

[0036] Preparation of molybdenum disulfide@graphdiyne composites:

[0037] (1) Under a nitrogen atmosphere, 80 mg of hexa(trimethylsilyl-ethynyl)benzene (HEB-TMS) and 1 mL of tetra-n-butylammonium fluoride were sequentially added to a reaction flask containing 40 mL of dichloromethane (DCM). Trihydrate (TBAF), stirred at 4° C. for 30 min to obtain a mixture, then the above mixture was washed twice with 50 mL of deionized water, and then dried with anhydrous magnesium sulfate to obtain a hexaethynylbenzene solution.

[0038](2) dropping the hexaethynylbenzene solution obtained in step (1) into a round bottle containing cobalt acetate and pyridine, wherein the addition ratio of the hexaethynylbenzene solution to cobalt acetate and pyridine is 1 mg / mL: 20 mg: 15 mL, The reaction was carried out at 40°C for 10h. After the reaction was completed, it was washed with pyridine, dimethylformamide, 1M HCl and deionized water in sequence, and dried to obtain graphdiyne (GDY) powder.

...

Embodiment 3

[0041] Preparation of molybdenum disulfide@graphdiyne composites:

[0042] (1) Under a nitrogen atmosphere, 90 mg of hexa(trimethylsilyl-ethynyl)benzene (HEB-TMS) and 1 mL of tetra-n-butylammonium fluoride were sequentially added to a reaction flask containing 60 mL of dichloromethane (DCM). Trihydrate (TBAF), stirred at 0 °C for 20 min to obtain a mixture, then the above mixture was washed twice with 50 mL of deionized water, and then dried with anhydrous magnesium sulfate to obtain a hexaethynylbenzene solution.

[0043] (2) dropping the hexaethynylbenzene solution obtained in step (1) into a round bottle containing cobalt acetate and pyridine, wherein the addition ratio of the hexaethynylbenzene solution to cobalt acetate and pyridine is 1 mg / mL: 20 mg: 10 mL, React at 50°C for 15h. After the reaction was completed, it was washed with pyridine, dimethylformamide, 1M HCl and deionized water in sequence, and dried to obtain graphdiyne (GDY) powder.

[0044] (3) adding the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com