A filter for emergency core cooling system with both filtering and drainage functions

An emergency core and cooling system technology, which is applied to fixed filter element filters, reactors, filtration and separation, etc., can solve the problems of small self-priming pump flow, prolonged drainage time, and influence on the progress of refueling of nuclear power plants, so as to avoid The effect of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below by means of the accompanying drawings and specific embodiments.

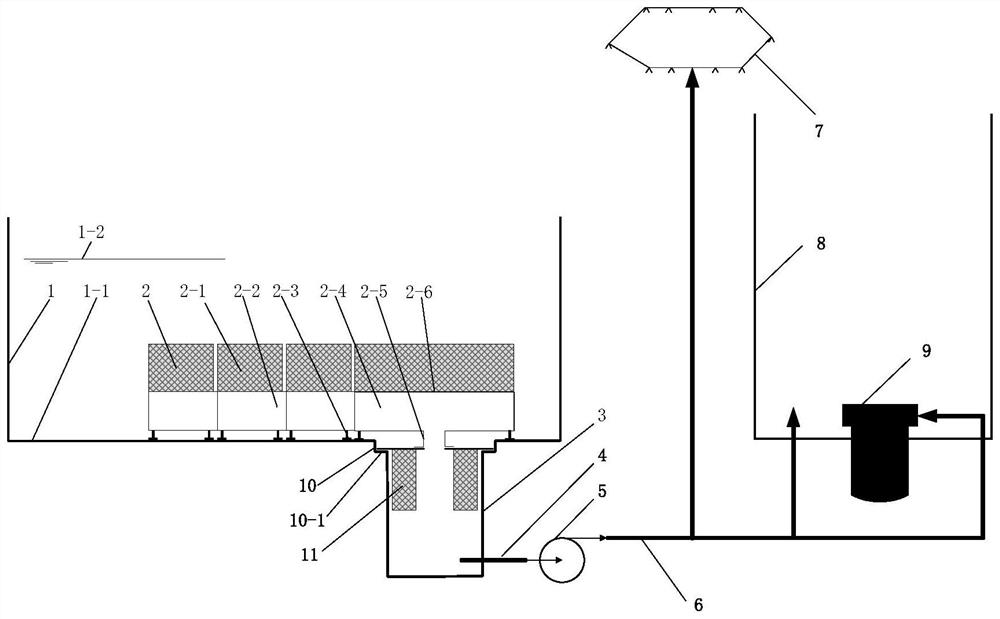

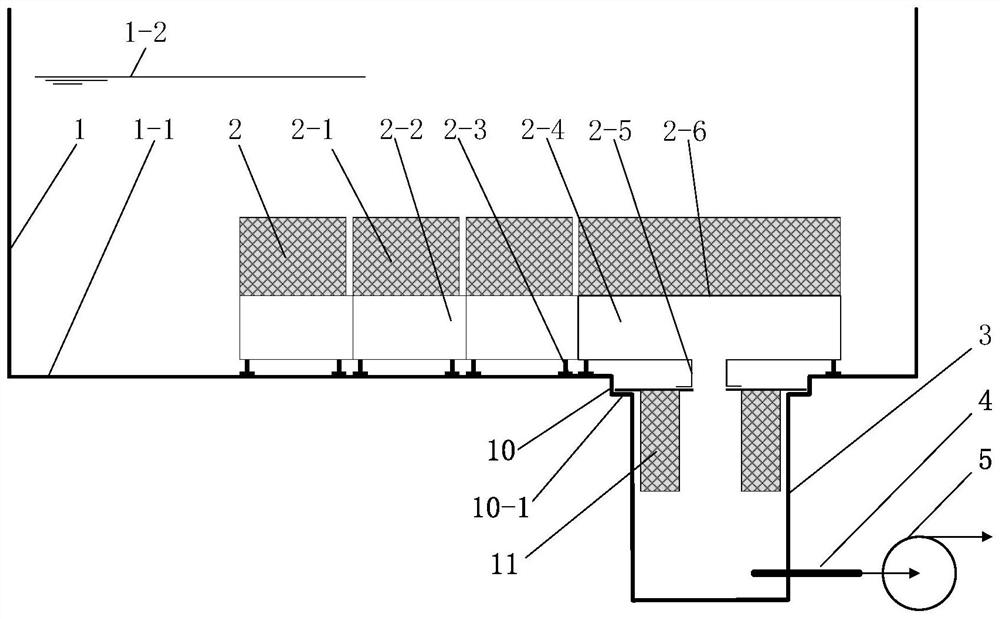

[0047] Such as figure 2 As shown, the core design of the present application is based on the traditional ECCS filter, which adds pit mouth groove 10 and sinking filter assembly 11 .

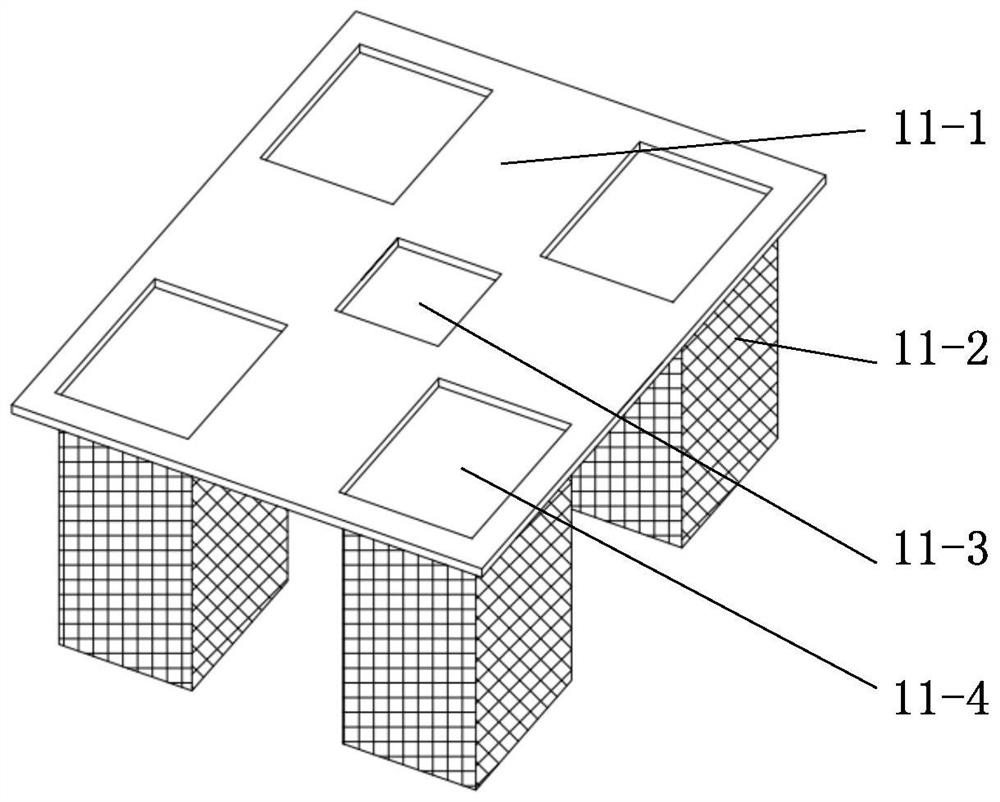

[0048] The ECCS filter includes an upper filter assembly 2 installed at the bottom of the built-in refueling water tank 1 , a pumping sump 3 installed below the built-in refueling water tank 1 , and a submerged filter assembly 11 located in the pumping sump 3 .

[0049] The upper filter assembly 2 includes an equipment support leg 2-3 installed on the bottom surface 1-1 of the built-in refueling water tank, a filter screen flow channel 2-2 installed through the equipment support leg 2-3 and a pit mouth flow channel 2-4, installed on The filter screen 2-1 on the filter screen flow channel 2-2 and the pit mouth flow channel 2-4; the connecting piece 2-5 is installed at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com