Spiral cross fuel element small villiaumite cooling high-temperature reactor core

A technology for fuel elements and high-temperature reactors, applied to fuel elements, reactor fuel elements, cooling devices, etc., can solve the problems of complex fuel cycle schemes, high fuel peak temperature, difficult installation and positioning, etc., to easily accommodate swelling deformation, reduce Stress, easy fixation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

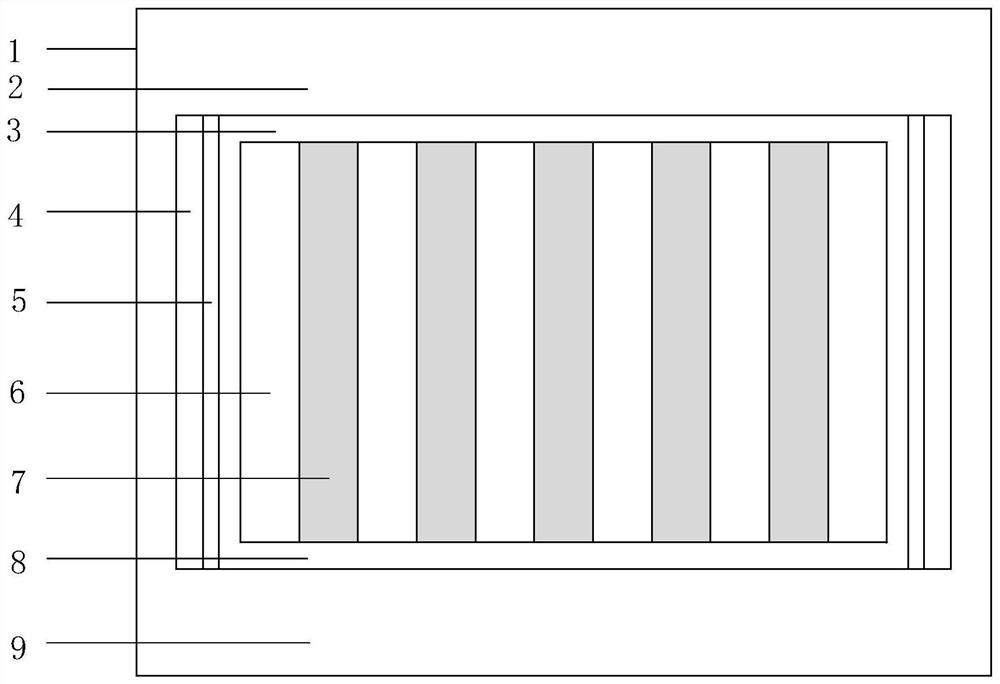

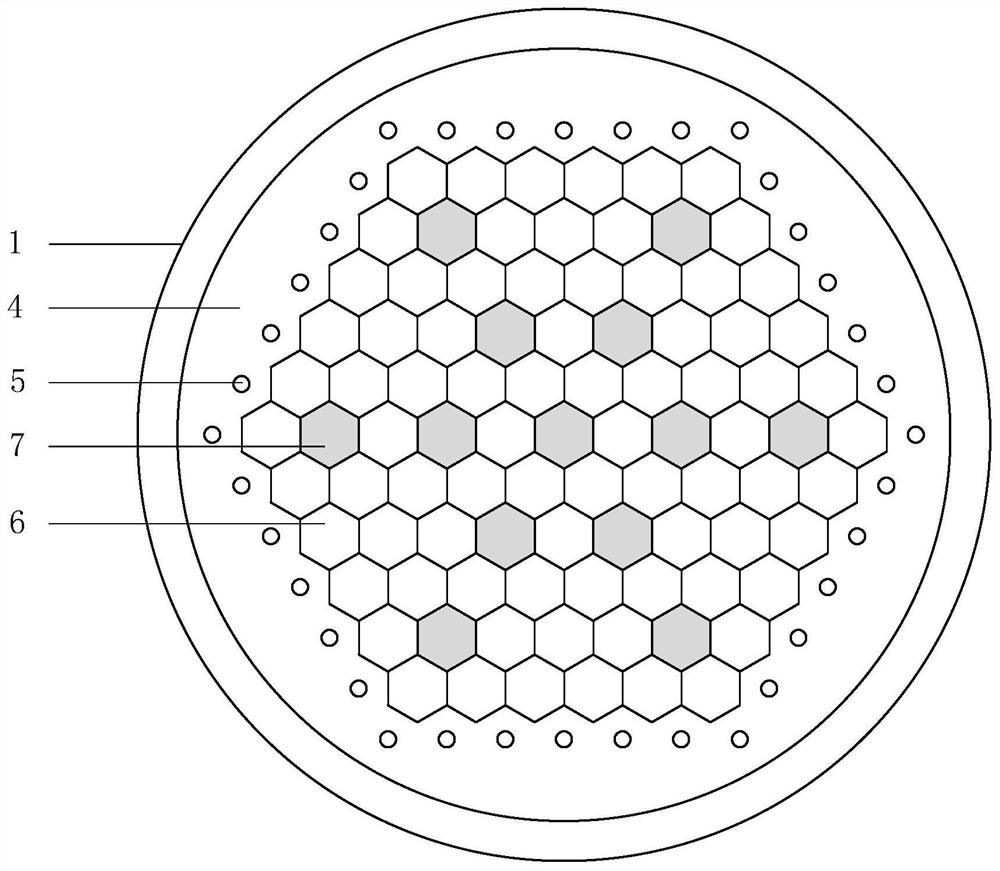

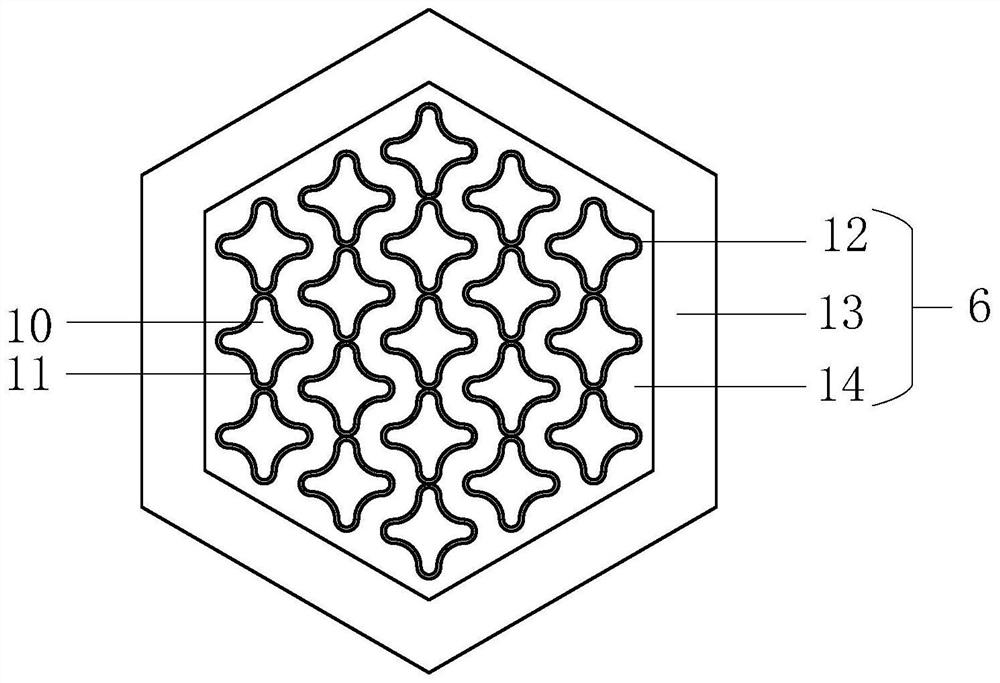

[0029] The present invention provides a small fluorine salt cooled high temperature reactor core of a spiral cross fuel element. The present invention will be further described in detail with reference to the accompanying drawings.

[0030] like figure 1 and figure 2 Shown is an embodiment of the spiral cross fuel element small fluorine salt cooled high temperature stack of the present invention.

[0031] It includes a core shroud 1, an upper chamber 2 located in the core shroud 1, a lower chamber 9, an upper reflection layer 3 located between the upper chamber 2 and the lower chamber 9, a radial reflection layer 4, and a coolant Bypass channel 5, fuel assembly 6, control rod assembly 7 and lower reflection layer 8; said fuel assembly 6 and control rod assembly 7 are located between radial reflection layer 4, upper reflection layer 3 and lower reflection layer 8, fuel assembly 6 and the periphery of the control rod assembly 7 include 36 coolant bypass channels 5, the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com