Hydraulic two-way recooling type heat dissipation type hydraulic hammer

A heat-dissipating, hydraulic hammer technology, used in impact drilling, reciprocating drilling rigs, fluid pressure actuating devices, etc., can solve the problems of temperature rise at the piston, reduced equipment work efficiency, temperature rise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

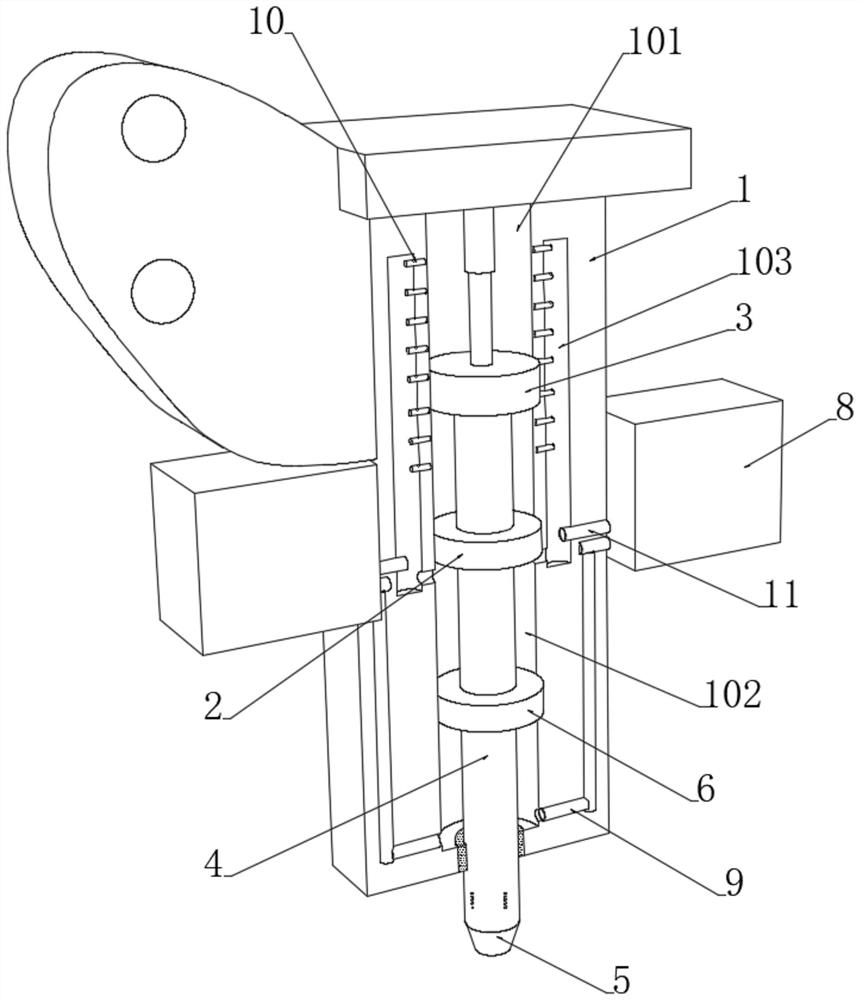

[0044] see Figure 1-5 , a hydraulic two-way back-cooling type heat-dissipating hydraulic hammer, including a cylinder body 1, the cylinder body 1 is formed by a pair of cylinder liners symmetrically arranged front and rear, and a connecting arm is arranged on one side of the cylinder body 1, which is easy to install the cylinder body 1 Installation, the cylinder body 1 is provided with a hollow cavity, and the middle part of the hollow cavity is provided with a fixed sleeve 2. The fixed sleeve 2 separates the hollow cavity into a hydraulic cavity 101 and a liquid storage cavity 102. The bottom end is connected with a drill rod 4, the lower end of the drill rod 4 penetrates the fixed sleeve 2 and extends to the liquid storage chamber 102, the lower end of the drill rod 4 penetrates the fixed sleeve 2 and extends to the liquid storage chamber 102, and the bottom end of the drill rod 4 is set through the tenon body. There is a drill hammer head 5, and both sides of the cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com