Totally-closed internal circulation self-dustfall granulation system, and method using same

An internal circulation and fully enclosed technology, which is applied in separation methods, chemical instruments and methods, and dispersed particle filtration, can solve problems such as waste of materials, waste of plant land resources, and pollution of the plant environment, so as to reduce production costs and prevent air pollution. material, to ensure the effect of the factory environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

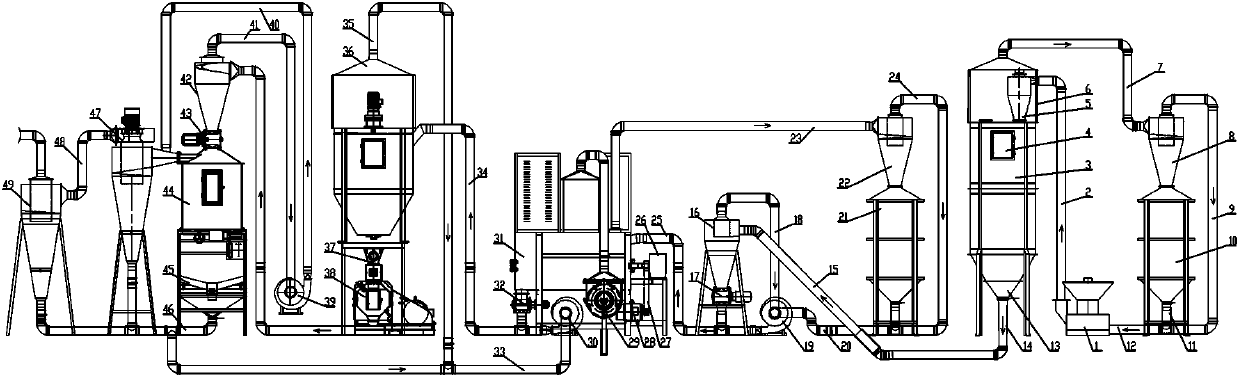

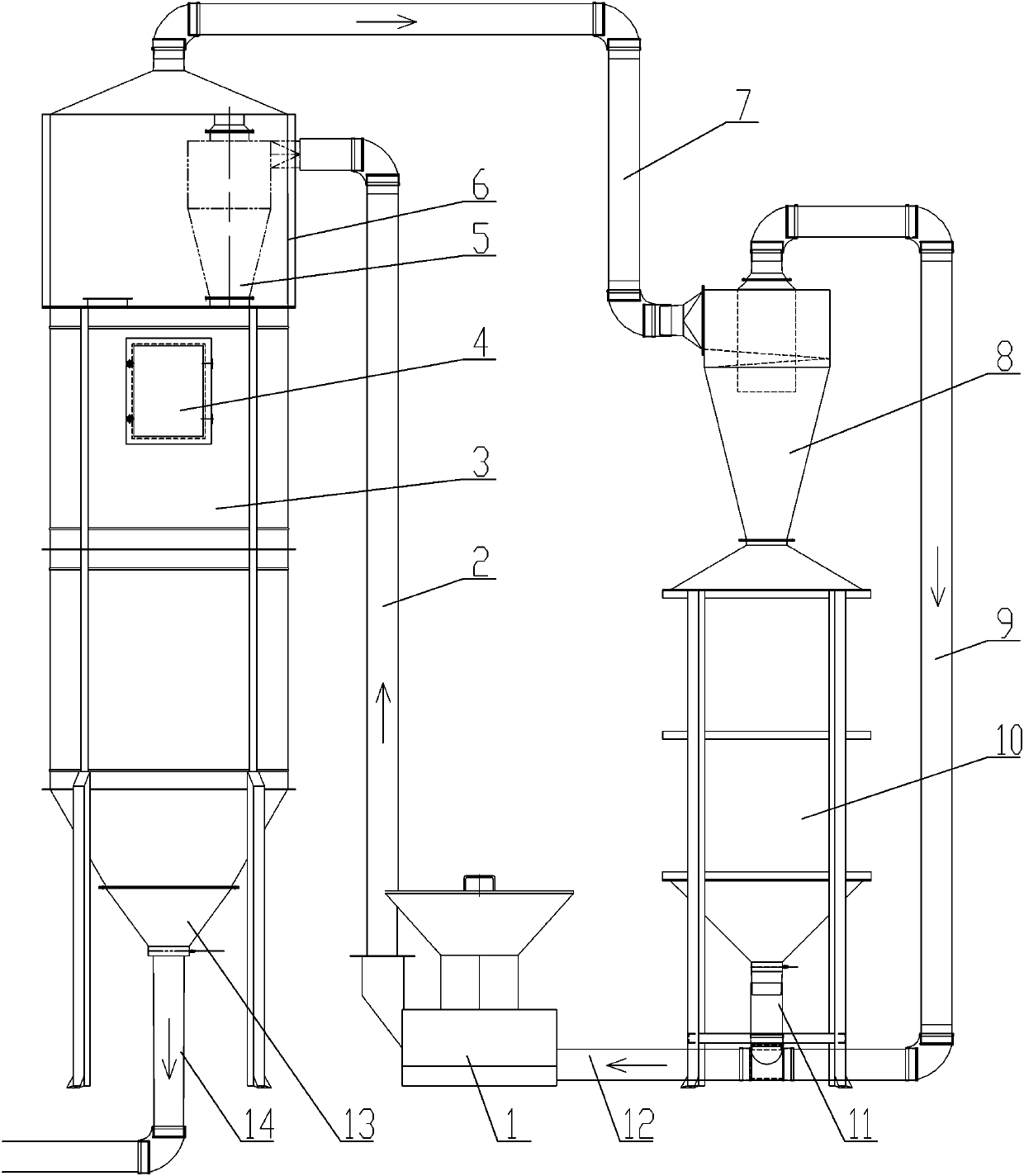

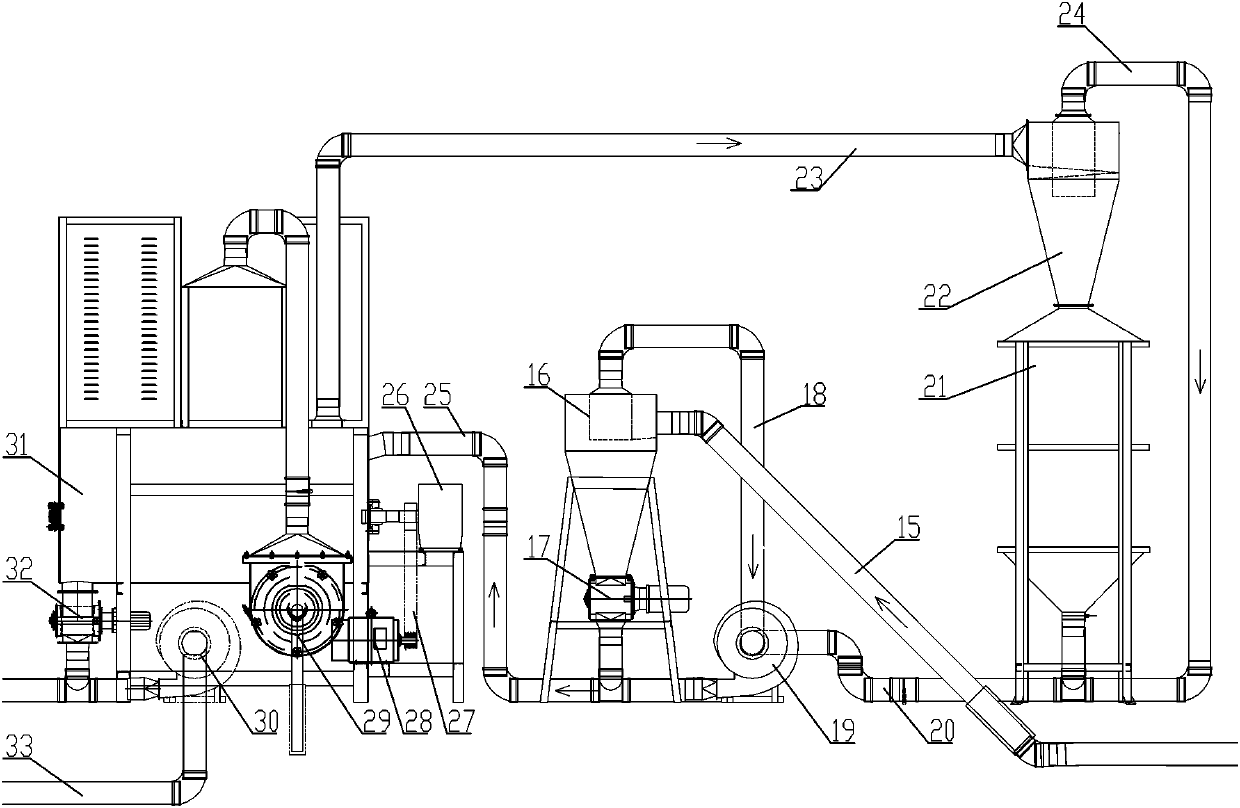

[0042] see Figure 1-4 , a fully enclosed, internal circulation, self-falling dust granulation system, which includes a coarse material crushing system for recycling and crushing straw materials, the powder output pipe 14 of the coarse material crushing system passes through the first conveying pipe 15 and the first wind force The conveying system is connected; the discharge port of the first wind conveying system is connected with the mixer 31 through the second conveying pipe 25; the mixer 31 is equipped with a fine material crushing device for grain material crushing; the mixer The discharge port of 31 is connected with the blanking tower 36 through the second wind power conveying system and the third conveying pipe 34; the discharge port of the blanking tower 36 is connected with the conditioner 37; the discharge of the conditioner 37 The port is connected with the granulator 38 for granulation; the outlet of the granulator 38 is connected with the drying tower 44 through ...

Embodiment 2

[0054] Any one of the fully enclosed, internal circulation, self-dusting granulation system for granulation method, comprising the following steps:

[0055] Step1: The straw and forage are crushed by the coarse material grinder 1, and the crushed grass powder is sent to the powder storage tower 3 through the pipeline for storage. The third dust removal device 8 collects the suspended dust and enters the coarse material crushing again. In machine 1, a self-circulation is completed;

[0056] Step2: Send the grass powder into the mixer 31 through the first wind conveying system and the first conveying pipe 15, and mix it with the grain concentrate pulverized by the concentrate pulverizer 29;

[0057] Step3: The mixed material is sent to the blanking tower 36 through the second wind conveying system and the third conveying pipe 34;

[0058] Step4: Blanking tower 36 evenly transports the material to the pelletizing system composed of conditioner 37 and feed pellet machine 38 to co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com