Environment-friendly mixed refrigerant, preparation method and refrigeration equipment

A technology of mixed refrigeration and refrigeration equipment, applied in the field of refrigeration working fluid, can solve the problems of inability to achieve R22 substitution, unable to solve the requirement of low GWP of flammable working fluid, etc. poor performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

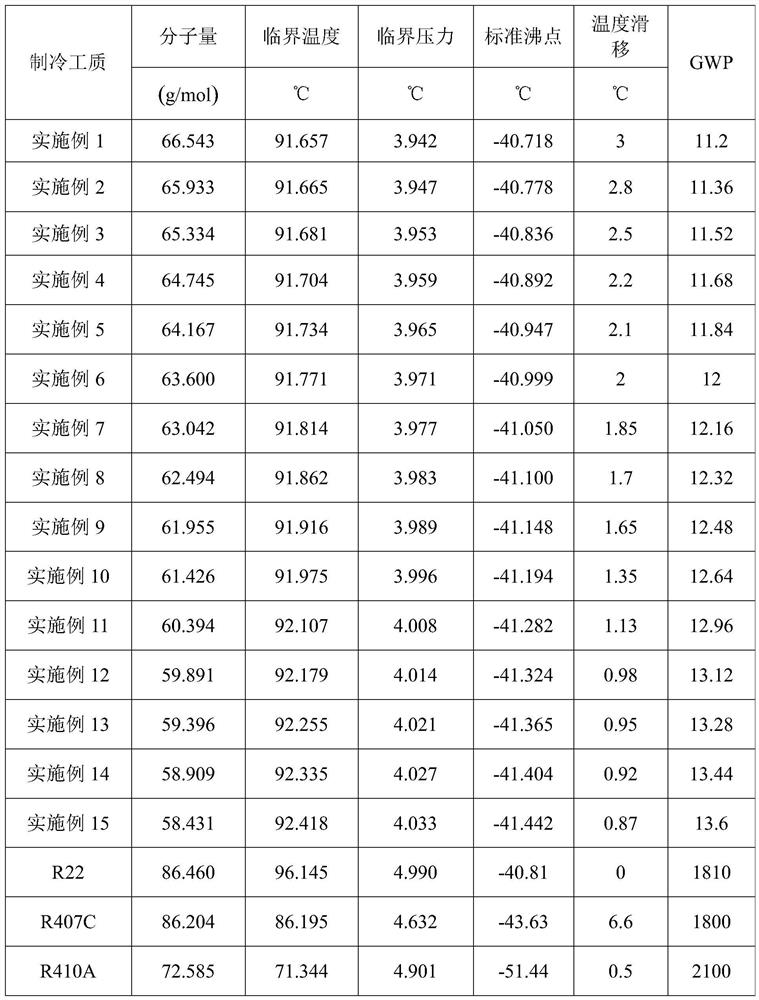

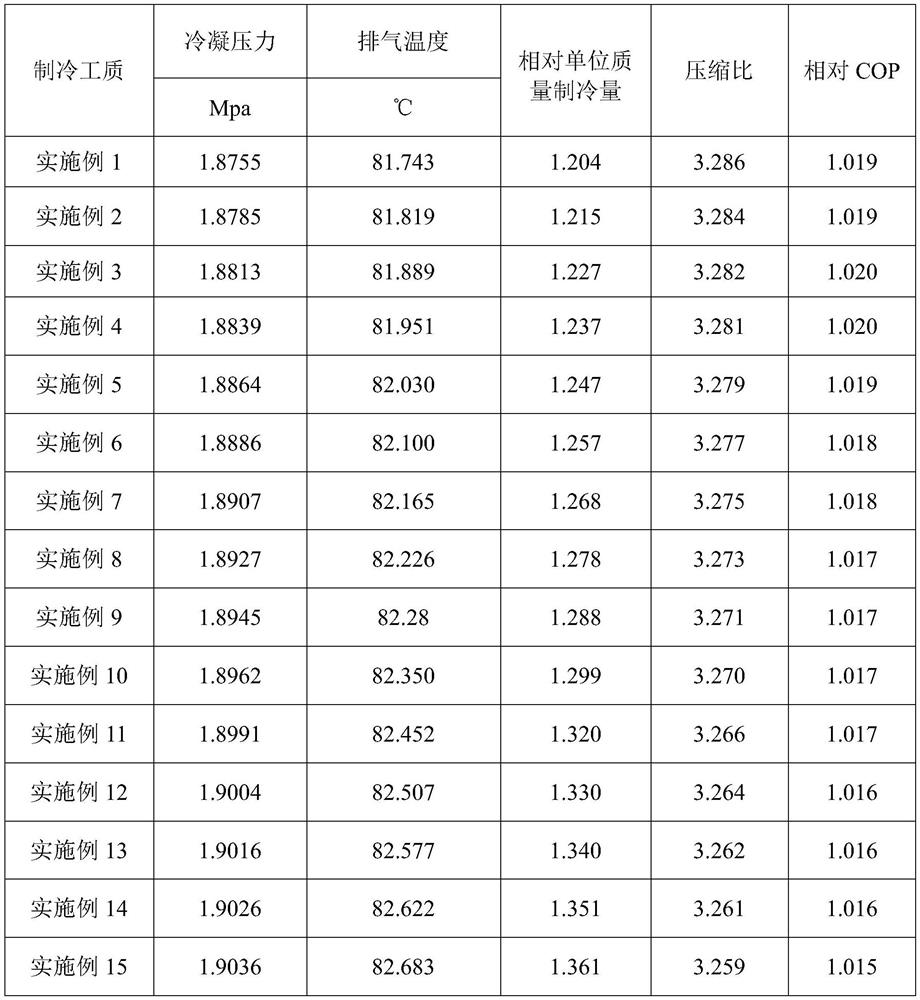

Embodiment 1

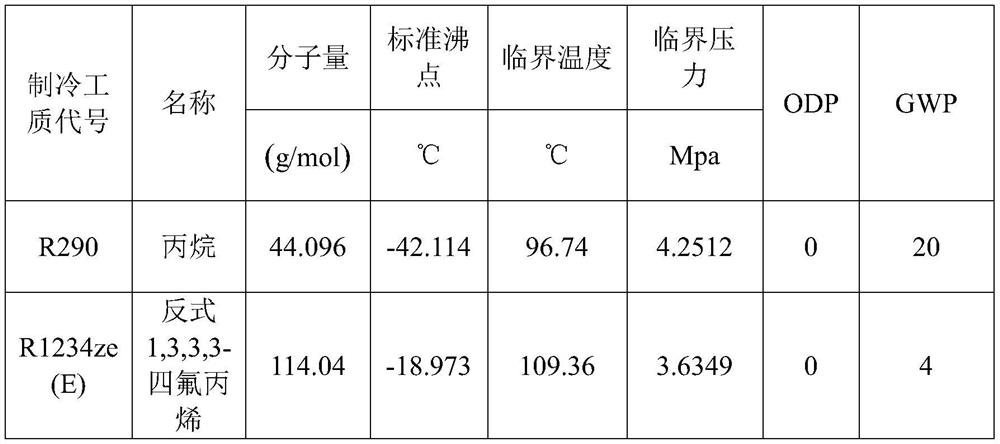

[0059] Example 1: The two components of propane (R290) and trans-1,3,3,3-tetrafluoropropene (R1234ze(E)) are physically mixed in a liquid state at a mass percentage of 45:55 , to obtain a high-efficiency and environmentally friendly mixed refrigerant.

[0060] That is, if the total mass of the mixed refrigerant is M, the mass M is multiplied by 45% propane; the mass M is multiplied by 55% trans-1,3,3,3-tetrafluoropropene; these two The components are physically mixed evenly in the liquid state, and the following expressions are analogous.

Embodiment 2

[0061] Example 2: The two components of propane (R290) and trans-1,3,3,3-tetrafluoropropene (R1234ze(E)) are physically mixed in a liquid state at a mass percentage of 46:54 , to obtain an environmentally friendly mixed refrigerant.

Embodiment 3

[0062] Example 3: The two components of propane (R290) and trans-1,3,3,3-tetrafluoropropene (R1234ze(E)) are physically mixed in a liquid state at a mass percentage of 47:53 , to obtain an environmentally friendly mixed refrigerant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com