A preparation process and device of ultra-short fiber for diapers

A technology of ultra-short fiber and preparation process, which is applied in the chemical characteristics of fibers, textiles and papermaking, and non-bundle formation, etc. It can solve the problem of polluting the workshop environment, short fibers are easily lifted by the wind, water absorption and stability need to be improved, etc. problems, to achieve the effect of improving the liquid absorption capacity, the cross-linking structure is remarkable, and the pores are dense.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

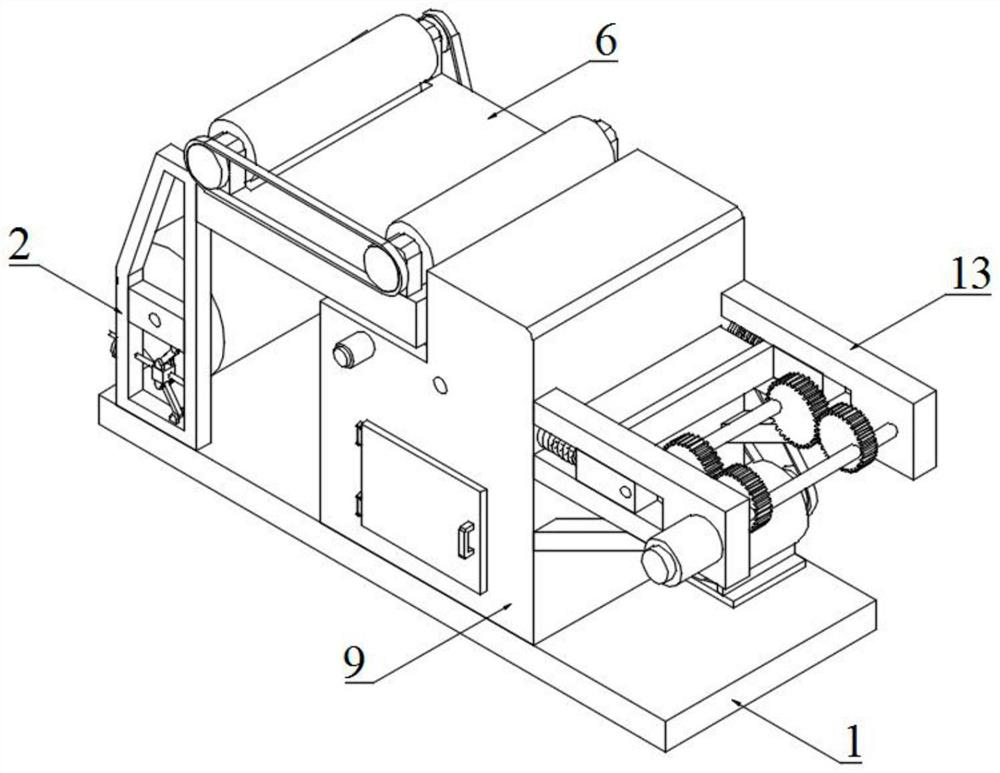

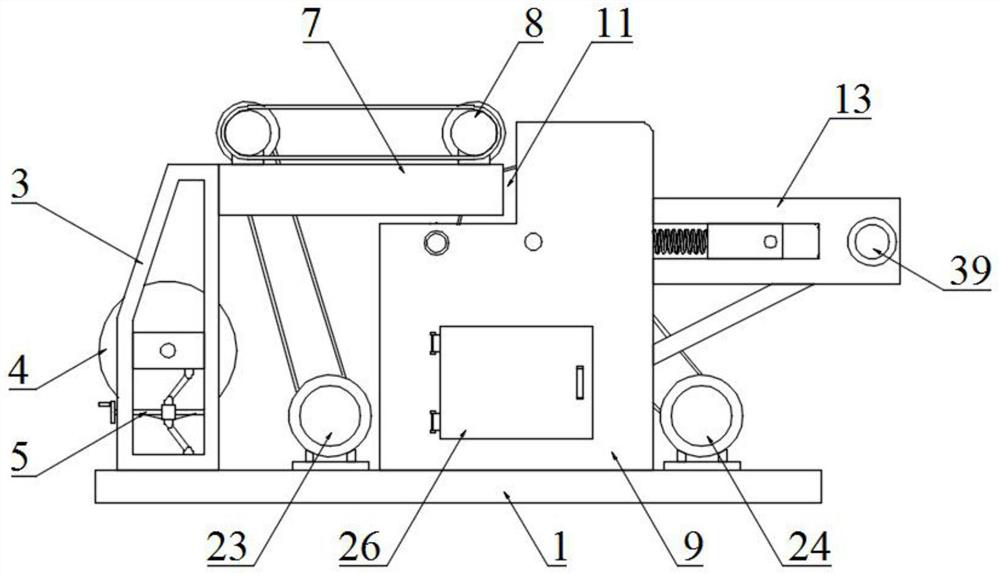

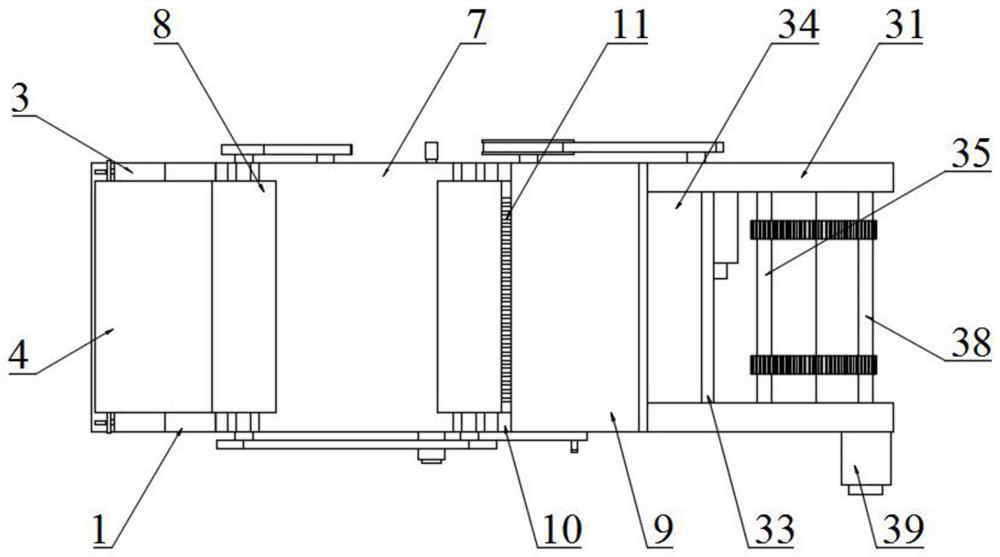

Image

Examples

Embodiment 1

[0042] A process for preparing ultra-short fibers for diapers. The ultra-short fibers for diapers include the following raw materials in parts by weight: 80 parts of acrylic acid, 10 parts of 2-acrylamide-2-methylpropanesulfonic acid, 2 parts of nanocellulose, ammonium persulfate 8 parts, N, 1 part of N-methylenebisacrylamide, and its preparation process comprises the following steps:

[0043] S1. Slowly add acrylic acid monomer into 25wt% NaOH solution in a water bath at 2-8°C, stir while adding, and carry out neutralization reaction, and configure acrylic acid monomer neutralizing solution;

[0044] S2. Dissolving 2-acrylamido-2-methylpropanesulfonic acid in distilled water, slowly adding 25wt% NaOH solution, stirring and reacting, and preparing a neutralizing solution of 2-acrylamido-2-methylpropanesulfonic acid;

[0045] S3, adding nanocellulose into ice water at 0-4°C for ultrasonic dispersion for 20 minutes, and preparing a cellulose dispersion;

[0046] S4. Add the cel...

Embodiment 2

[0050] A process for preparing ultra-short fibers for diapers. The ultra-short fibers for diapers include the following raw materials in parts by weight: 70 parts of acrylic acid, 20 parts of 2-acrylamide-2-methylpropanesulfonic acid, 1.5 parts of nanocellulose, ammonium persulfate 6 parts, N, 2 parts of N-methylenebisacrylamide, its preparation process comprises the following steps:

[0051] S1. Slowly add acrylic acid monomer into 20wt% NaOH solution in a water bath at 2-8°C, stir while adding, and carry out neutralization reaction, and prepare acrylic acid monomer neutralizing solution;

[0052] S2. Dissolving 2-acrylamido-2-methylpropanesulfonic acid in distilled water, slowly adding 20wt% NaOH solution, stirring and reacting, and preparing a neutralizing solution of 2-acrylamido-2-methylpropanesulfonic acid;

[0053] S3, adding nanocellulose into ice water at 0-4°C for ultrasonic dispersion for 20 minutes, and preparing a cellulose dispersion;

[0054] S4. Add the cellul...

Embodiment 3

[0058] A process for preparing ultra-short fibers for diapers. The ultra-short fibers for diapers include the following raw materials in parts by weight: 60 parts of acrylic acid, 130 parts of 2-acrylamido-2-methylpropanesulfonic acid, 1 part of nanocellulose, potassium persulfate 5 parts, N, 2 parts of N-methylenebisacrylamide, and its preparation process comprises the following steps:

[0059] S1. Slowly add acrylic acid monomer into 25wt% NaOH solution in a water bath at 2-8°C, stir while adding, and carry out neutralization reaction, and configure acrylic acid monomer neutralizing solution;

[0060] S2. Dissolving 2-acrylamido-2-methylpropanesulfonic acid in distilled water, slowly adding 25wt% NaOH solution, stirring and reacting, and preparing a neutralizing solution of 2-acrylamido-2-methylpropanesulfonic acid;

[0061] S3, adding nanocellulose into ice water at 0-4°C for ultrasonic dispersion for 10-30 minutes, and preparing a cellulose dispersion;

[0062] S4. Add th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com